This week’s selection is the innovative Kinematic Petals Dress by Nervous System.

Nervous System has a long history of developing rather incredible 3D printed designs, initially in jewelry and more recently with complete dresses. Their latest venture, the Kinematic Petals Dress, pushes the design envelope even further.

Here’s their overview of the project:

Inspired by petals, feathers, and scales, we developed a new textile language for Kinematics where the interconnected elements are articulated as imbricating shells. Like our previous garments, this dress can be customized to the wearer’s body through a 3D scan, and additionally, each element is now individually customizable: varying in direction, length, and shape.

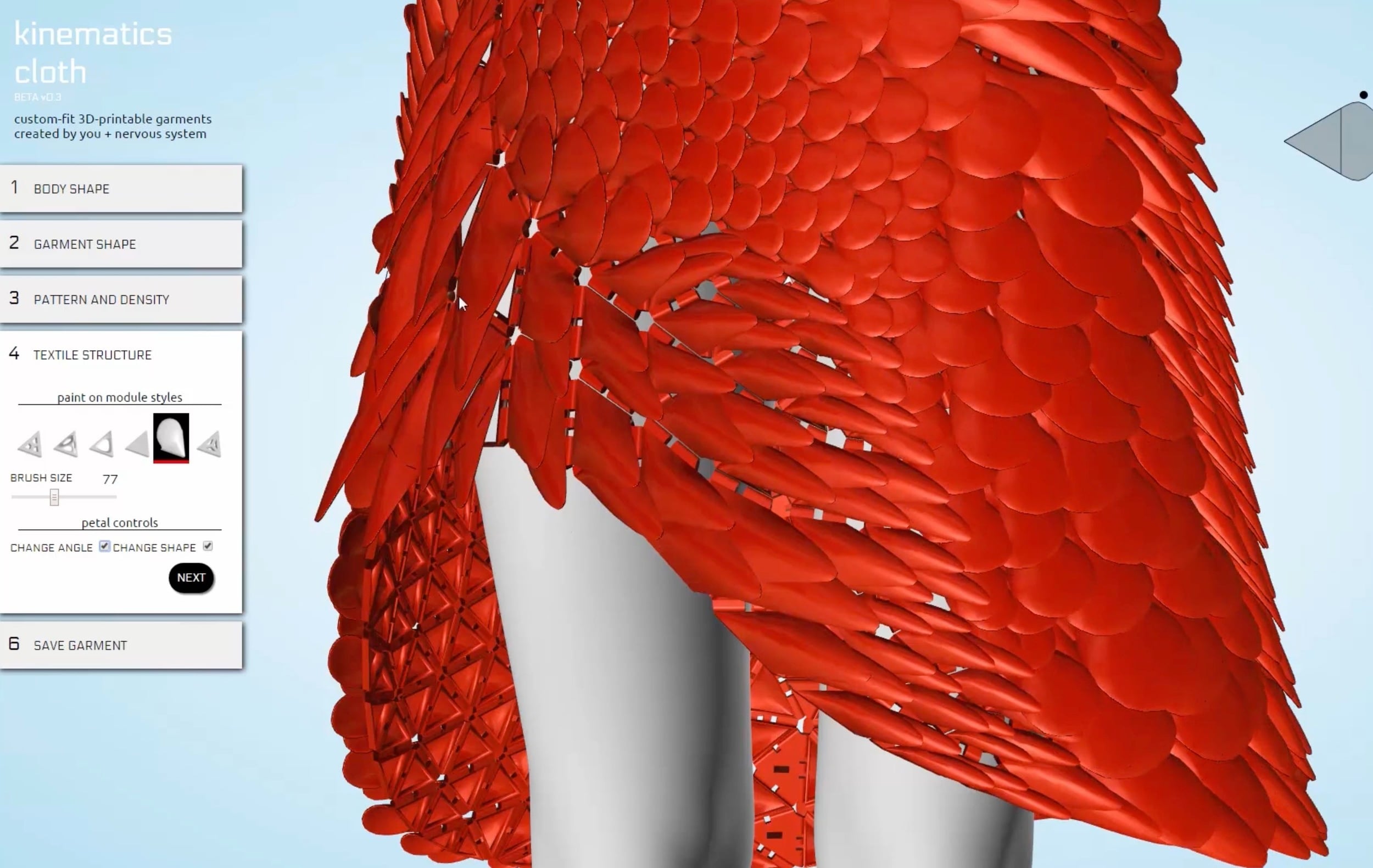

Yes, they’ve made a “textile language”, which I presume is a method for rapidly designing such highly complex structures. The dress components are essentially a standard pattern that’s repeated many times, but with varying sizes and connections to neighboring elements. This explains how they can dynamically create a custom dress design using an online generator program, as shown here:

They didn’t just design a dress; no, instead they designed a dress-generating system! The number of unique dresses available from such a system is effectively infinite. Watch this video to see how it works:

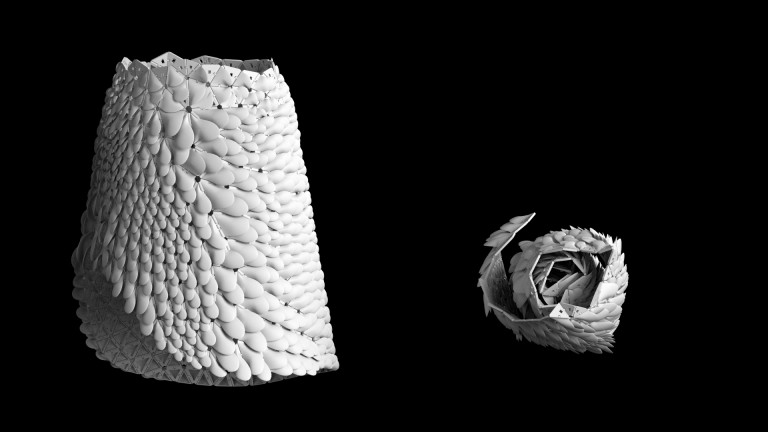

There are more fascinating aspects to this project. One that piques my interest is that the generated designs are provided in a “rolled up” fashion, such that the 3D model fits within the build volume of the intended 3D printers, which we suspect are the EOS line of powdered nylon equipment.

Thus, when you print this item, you can unfold it directly into wearable form, even though the dress is visually far larger than the printer’s maximum volume. Of course, this doesn’t literally happen, as the print will have to be cleaned of residual nylon powder, and the print must also be dyed to the correct color. But still, pulling a complete dress out of a 3D printer is quite a feat of design.

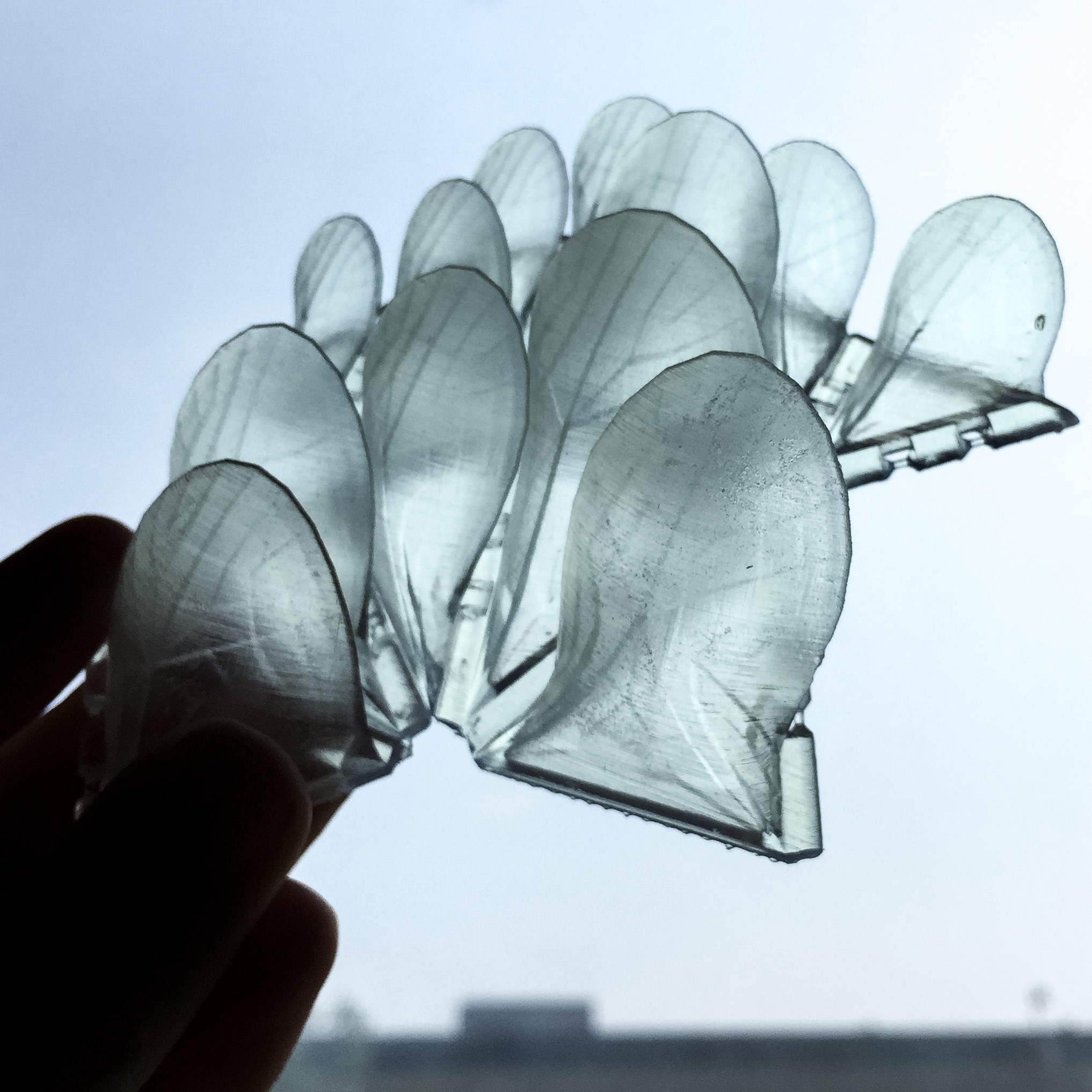

Folding is possible due to the unique hinged design; each cell is interlocked with its neighbors with tiny hinges. The rigid cells are transformed into a fabric-like structure by these hinges: holding a piece of it drapes over your fingers much like a traditional fabric would. They explain further:

Petals protrude from the underlying framework of tessellated triangular panels, sheathing the body in a directional landscape of overlapping plumes. Each interlocking component of the dress is rigid, but in aggregate, they behave as a continuous textile. The dress is 3D-printed in durable nylon plastic by Selective Laser Sintering. While the design is composed of more than 1600 unique pieces interconnected by more than 2600 hinges, it emerges from the 3D printer fully assembled and ready to wear. We employ a smart folding strategy to compress Kinematics garments into a smaller form for efficient fabrication. By folding the garments prior to printing them, we can make complex structures larger than a 3D printer, that unfold into their intended shape.

The Kinematics Petal Dress was commissioned by Boston’s Museum of Fine Arts for an exhibition focused on the intersection of fashion and technology, of which the Kinematics Petal Dress must certainly be a prime example.

If you’re in Boston any time before July 10th, you can see this piece in person.

Via Nervous System