We first saw the MarkForged desktop 3D printer in San Diego 2014, where it surprised everyone with its ability to print carbon fiber. Two years later they’ve released the Mark Two.

The original MarkForged machine was not notable in that it had the ability to print with two materials, but instead that one of the materials could be a very strong carbon fiber material. This enabled the machine to print a nylon part that included embedded carbon fiber elements that could vastly improve the strength of the print. Even better, the machine could also print Kevlar and Nylon.

In between the announcement of the original machine and today, the company has spent considerable effort developing a very sophisticated cloud-based software suite to accompany the hardware. It can literally automatically determine an optimum recommended strength pattern for a given object. This was really a requirement to make the machine successful, as the ability to intelligently embed strong materials was not something found in commonly available 3D modeling software. So they made it themselves, and as far as we can tell, quite well.

This week the company announced the Mark Two, stepping back into the world of hardware. What’s improved? It seems that they’ve managed to speed up the printing of carbon fiber by 40%, likely by a combination of tweaks to both hardware and materials.

The Mark Two can “Reinforce features 15 times smaller than before”. This relates to the minimum size of the carbon fiber extrusions, which previously had somewhat coarse limits. At the time of the announcement, ANY carbon fiber capability was revolutionary, but now the machine is much more capable. Essentially, it means that the Mark Two can produce finely detailed nylon objects with strong carbon fiber in more portions of the geometry. You can make more types of stronger things!

These improvements, combined with their ongoing software improvement process, make the Mark Two quite an attractive machine for designers and engineers wishing to create prototypes whose strength properties approach or match the final production versions.

It appears that the Mark One has been discontinued, as only the Mark Two appears in their online store. It’s available in three versions:

- The Mark Two Standard, USD$5,499, can 3D print in nylon, fiberglass and carbon fiber.

- The Mark Two Professional, USD$8,799, adds the ability to print in Kevlar, three sets of nozzles, and a local software option.

- The Mark Two Enterprise, USD$13,499, adds the ability to print in high-temp fiberglass and provides enterprise security features for group use in a larger environment.

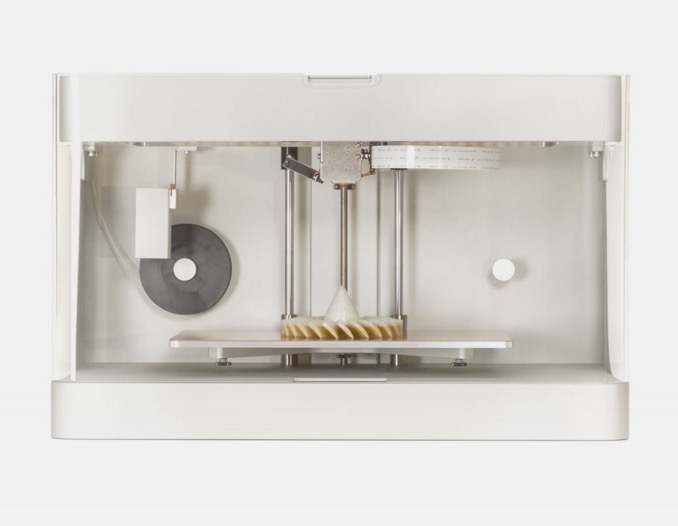

One more thing: the Mark Two, as was the Mark One, has a beautifully designed exterior that is clean and simple, much like their cloud-based software.

Via MarkForged