If you’re a student of 3D printing processes, pay attention: Nanoscribe has perhaps the most unusual process of them all.

Their company name gives it away somewhat: their process is designed to print small items. Very small items. Microscopic items. And it does so in a peculiar way.

Like other 3D printing processes, Nanoscribe’s process involves solidifying lines of material. But the difference is that their lines are only 0.25 microns wide! That’s equal to 0.00025mm!

With such incredible resolution, the Nanoscribe Photonic Professional GT desktop 3D printer can produce ridiculously detailed 3D objects of a size that’s almost invisible to the eye. The sample print at the top shows a very small object, but in fact this is considered to be a very LARGE object by Nanoscribe. It’s about the only thing they can reasonably show the public and still have it visible without a microscope.

Back to the printing process, which produces objects in polymer. It’s a liquid process, in which material is solidified, similar to other processes. However, that’s where things diverge.

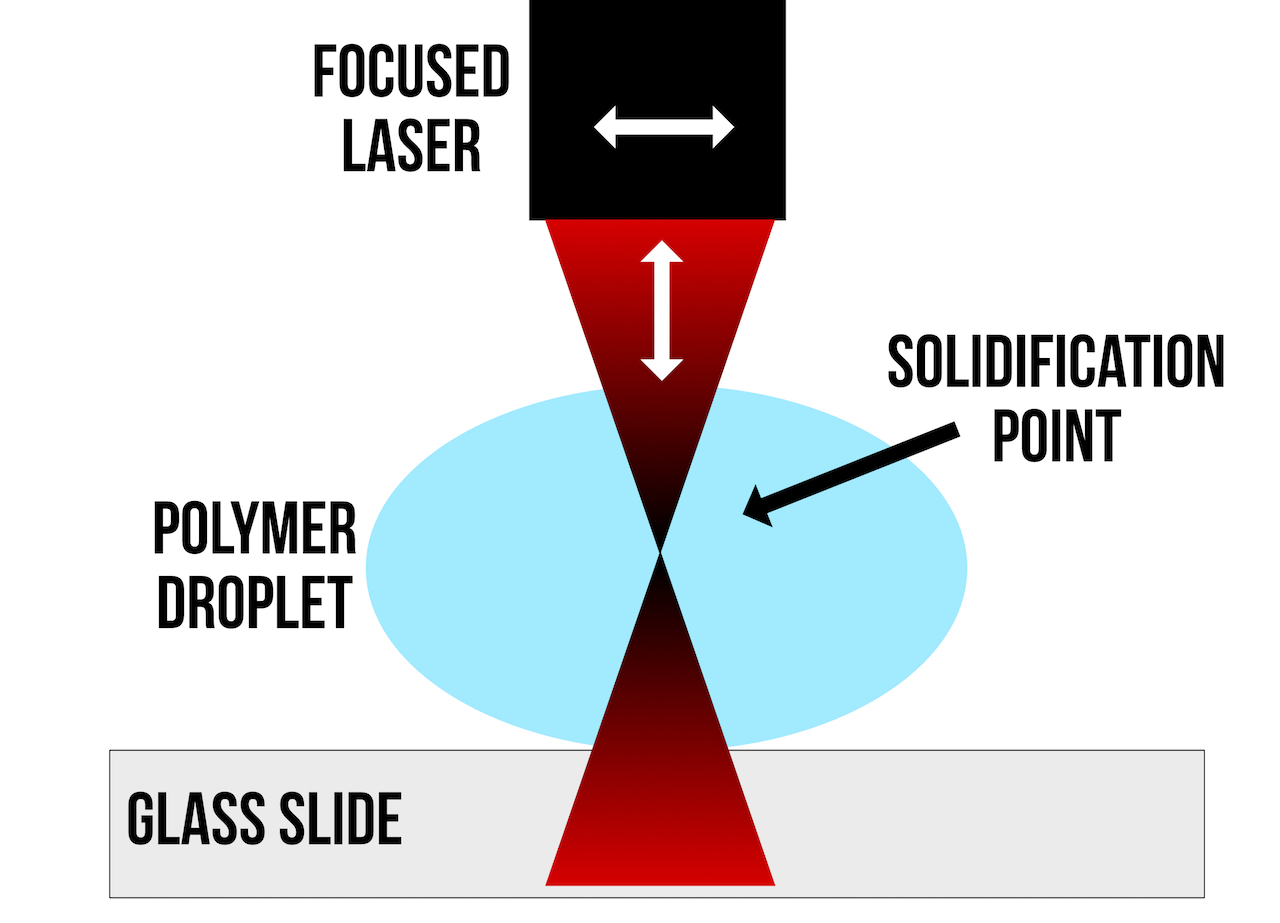

First you manually place a single droplet of liquid polymer on a glass slide. That’s it – you’ve now loaded all the materials for this process! Also, we’re told that the liquid is NOT a photopolymer; it’s a specialized substance designed by Nanoscribe.

Instead of having a powerful laser sweep across the liquid, the Nanoscribe process uses a laser that is focused to a pinpoint in space. Imagine a laser that’s largely out of focus, but does come to a focus point within a droplet of liquid polymer. The laser is not sufficiently powerful per volume at any other point to solidify the liquid.

Then the laser moves around within the droplet in three dimensions! It begins solidifying at the bottom and slowly adds lines and layers to build up a complete 3D object entirely within the droplet. An on- board camera captures the printing, as it would otherwise be impossible to observe.

This video shows how an object is printed in real time:

Nanoscribe first introduced this system in 2008 and in 2013 their GT system appeared, which increased print speed.

Who uses this type of invisible 3D printing? Their major clients – and they have over 100 system in place now – are research facilities wishing to create very tiny specialized objects. This replaces older “subtractive” techniques for producing microscopic parts in the same way that 3D printing is displacing CNC milling for some larger applications.

Another very promising area described to us is medical. Here’s how it works: the liquid polymer is mixed with fine magnetic material and a medical agent. Tiny objects are solidified with this mixture and then introduced into a human body. Exterior magnets are then used to “guide” the magnetic objects toward a particular part of the body, where the medical agent is released as the polymer dissolves. In other words, targeted drug delivery!

Pricing of this system varies depending on options selected.

Via Nanoscribe