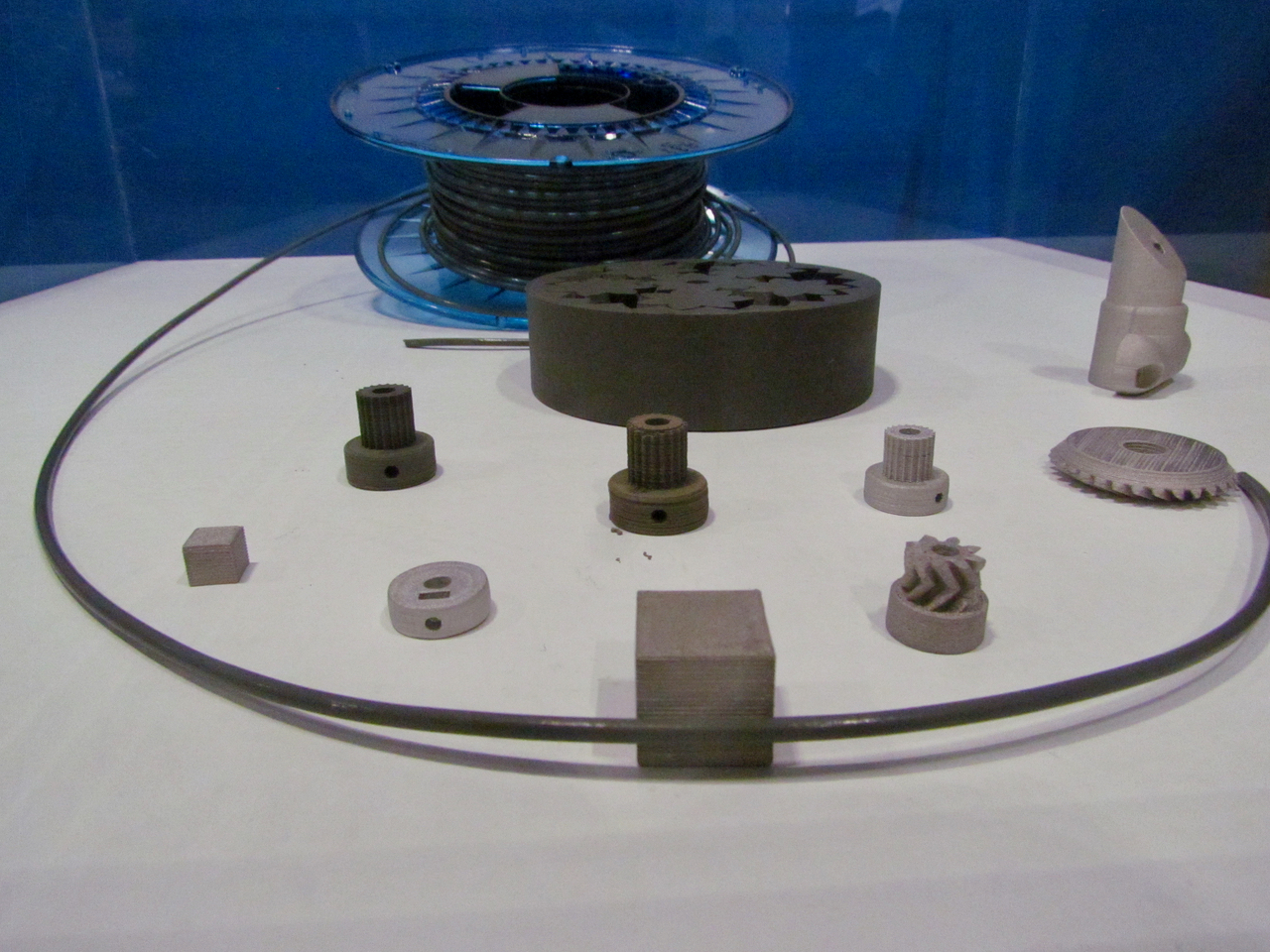

Hidden in the back of EVO-tech’s booth at FormNext was a very significant spool of material.

The Austrian company produces a professional desktop 3D printer capable of using exotic materials, but this material was of particular interest.

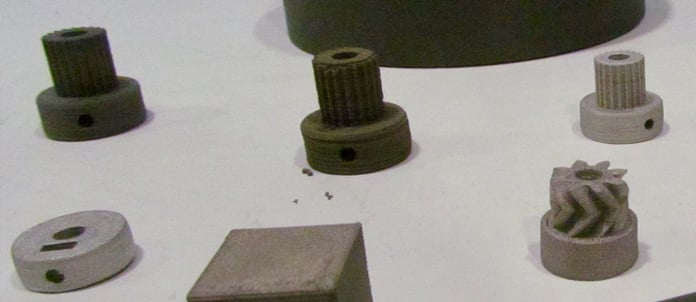

It seems they’ve even working with BASF to produce an unusual 3D printer filament that essentially permits metal prints. The filament contains a polymer and a great deal of stainless steel powder, and metal prints require a two-stage process.

First, the object is printed on EVO-tech’s machine, the EVO-lizer in the usual manner. Then, the “green” object is placed in a furnace and sintered at temperatures up to 1400C. This burns out the polymer and fuses the stainless steel together to form a solid, metal object.

In the process, the object shrinks proportionally as it loses polymer, so prints will have to account for this change in dimension.

We’re told this unusual filament is currently being beta tested by certain EVO-tech clients, but will be available for general purchase in mid-2017. Pricing? Not yet established.

This could be a very inexpensive way to get into 3D metal printing, but be aware that the resulting metal parts may – or may not – meet the engineering specifications required for your application.

Via EVO-tech