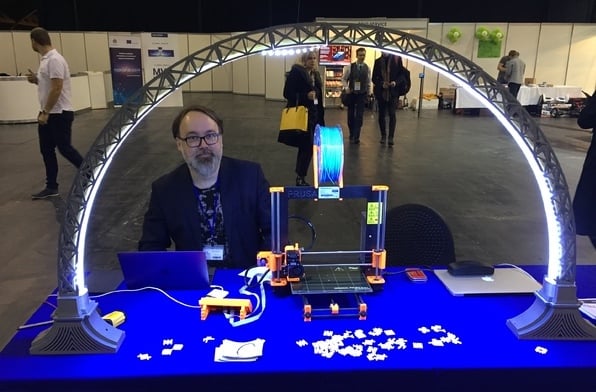

This week’s selection is the rather large LED Bridge lamp by Thingiverse contributor Janis Jakaitis.

Latvia-based Jakaitis wished to create a lamp that would illuminate his soldering station from all sides and avoid shadows. But rather than simply stringing up lengths of LED lights or purchasing a series of traditional lamps, he decided to design a massive structure to hold up the LEDs.

The LED bridge is exactly that: an enormous 3D printed “bridge” that spans your workspace. The LEDs, hung on the inner edge of the bridge, provide 180 degrees of brilliant illumination to mostly eliminate shadows.

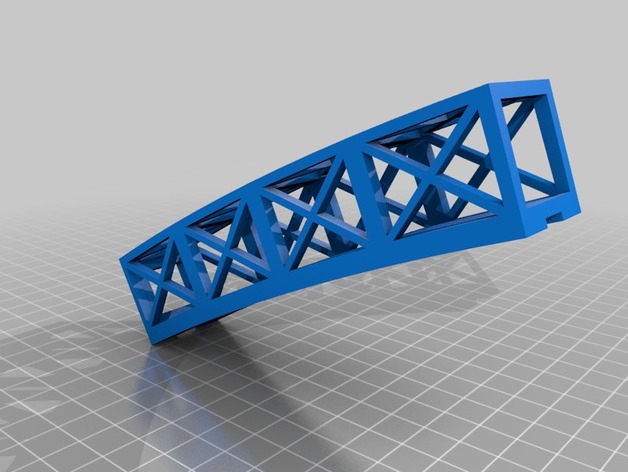

The bridge is composed of sixteen 3D models that must be printed and attached in an arc. There are two fancy-looking bases from which the bridge begins and ends. Jakaitis explains the design:

To me, the ArtDeco and imperial architecture (hello, Gotham City) are endless sources of excitement and admiration. I spent some time researching old Roman architecture on the Internet, to design the base for the bridge.

There are actually two different models of the LED Bridge. The first one involves custom segments that together make an appealing arc shape. However, due to public demand, Jakaitis produced a second version that instead uses a “universal” arc segment. While it is perhaps somewhat easier to print multiple copies of a single 3D model for the segments, the arc becomes perfectly circular, shown here.

I think I prefer the original arc, although the second model also includes a number of other minor improvements.

I should note that this project is considered advanced, simply because it requires a great deal of support material for the spindly structures. If your 3D printer has challenges with a lot of supports, then you’d best do a test on one piece to see how well it prints. Jakaitis recommends using Simplify3D to slice the models and generate easily removable supports.

Printing and assembling this item is not the end of the fun! With the LEDs you can develop some very unusual lighting scenarios, as shown in this video:

Jakaitis also suggests he’s working on future improvements:

I will soon add some magic into it – IR proximity sensors inside each segment to switch it on and off by the hands gesture and three rotary encoder knobs to adjust RGB components of the led strip.

Both 3D models are freely available for download on Thingiverse.

Via Thingiverse (Original) and Thingiverse (Universal)