A 3D printing experiment demonstrates how both success and tragedy in the industry.

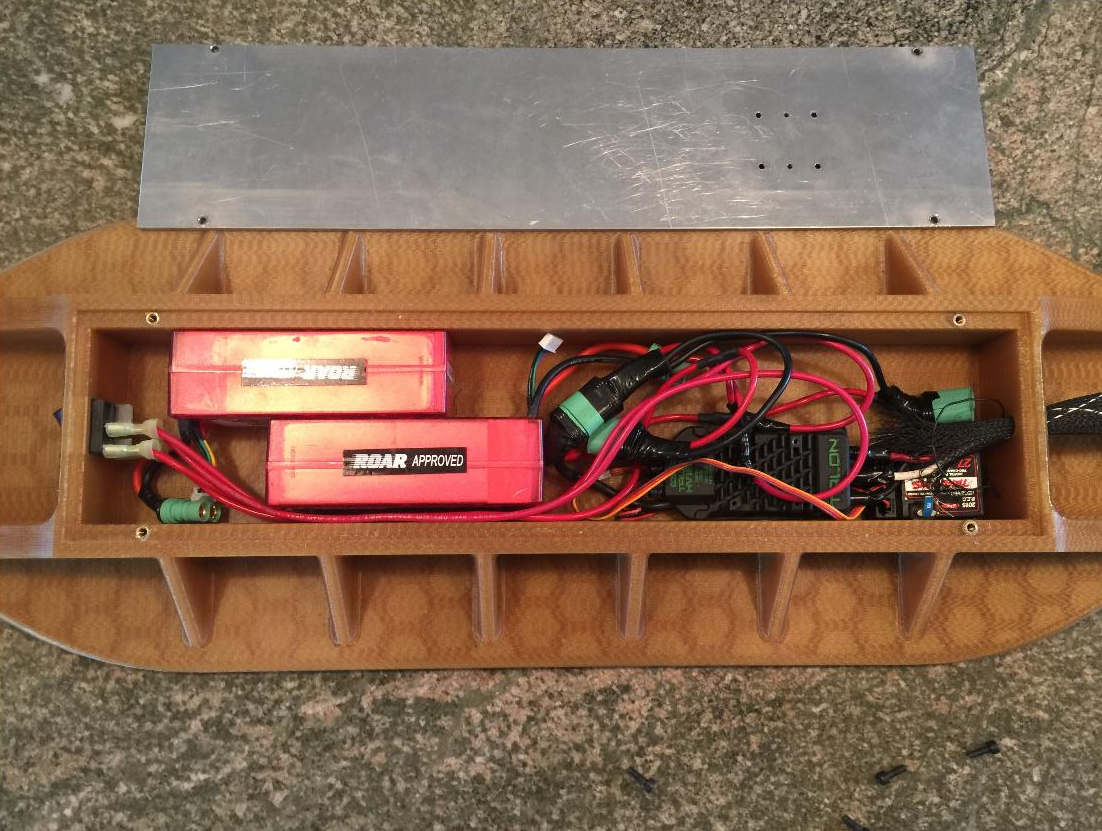

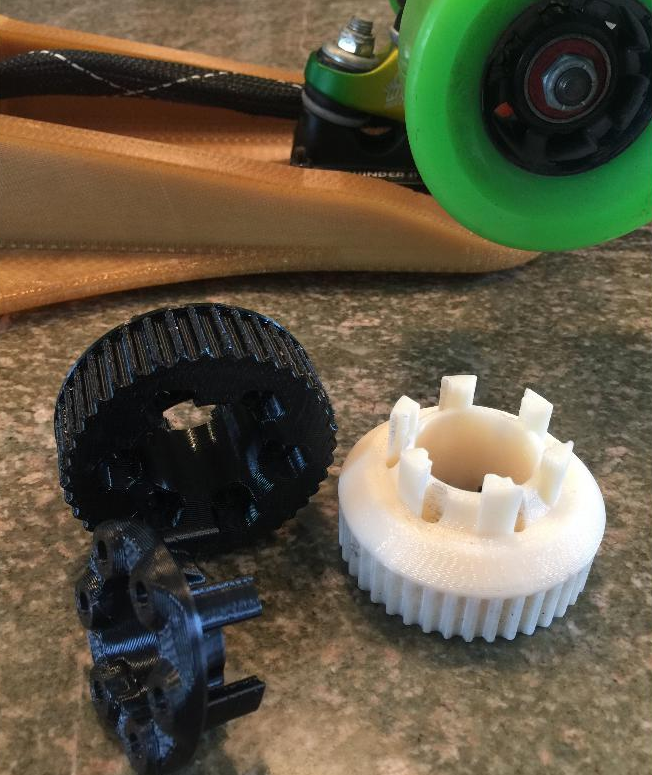

Reddit contributor tallaustin posted images of his custom 3D printed longboard, shown at top. tall austin was an intern at Stratasys Research & Development (a place we visited a few weeks ago), where he was able to access the equipment necessary to 3D print the longboard.

It took a couple of attempts to complete this print, including an initial version printed in nylon (note large break on the left side above), which apparently wasn’t strong enough. The final version was 3D printed in Stratasys’ ULTEM 1010 material, known for strength and high heat resistance. Which machine was used? The Fortus 900mc, the largest plastic extrusion machine currently sold by Stratasys, although there’s bigger machines coming in the future.

The resulting longboard is more than sufficiently strong to support the rider, as ULTEM is a powerful material and the longboard was printed solid – 100% infill over a six-day period. It also is made from a custom designed and sized 3D model, so it’s ideal for the creator.

That’s the good news from this project: custom, high quality longboard produced on demand.

But there’s a darker side, too. According to tallaustin, the cost of 3D printing this longboard, if charged by a service bureau, might have been USD$8,000.

That’s an enormous amount for a single longboard.

Some point out that you could 3D print this on lesser equipment at a lower cost, but I’m skeptical. The ULTEM 1010 material requires a 400C hot end and a build chamber temperature of 220C, far above virtually all other 3D printers. You might be able to print the part on other machines, assuming you have the build volume, but I’m not sure you’d have the required strength.

And this is the conundrum with 3D printing these days: you can do anything, but it’s expensive.

Someday pricing will come down, but it may require the introduction of entirely new forms of 3D printing that are more efficient.

Via Reddit