Yesterday at the Consumer Electronics Show MCOR announced the Arke, a full RGB color desktop 3D printer, capable of producing intricately color textured objects at low cost.

The Ireland-based company had previously (and still does) produced the Iris, a lower-cost full RGB-color 3D printer. The new machine, the Arke, offers dramatically improved performance and also dramatically lowered costs. After a secret two-year effort, the company now may strongly build their business with this new machine.

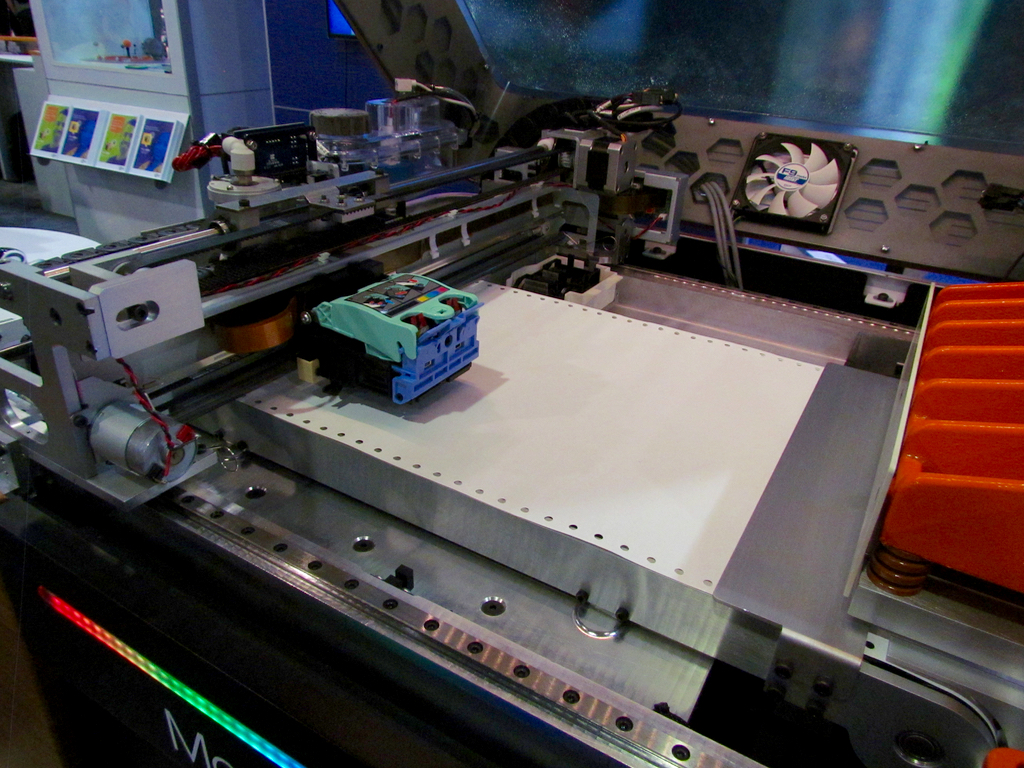

Like its predecessor, the Arke uses a unique paper-based 3D printing process in which layers of paper are glued together, with excess material cut away by a digitally controlled knife. The Iris achieved color 3D prints by pre-printing the colored edges of the objects on sheets of paper prior to gluing and cutting. The process worked very well, but the Arke takes the concept even further.

It seems that MCOR spent considerable time working with their clients (and potential clients) to understand their needs, which have been implemented in the form of the new Arke. According to CEO Conor MacCormack, the top three requirements were: Reliability, Price and Color.

The Arke meets all these and more by a series of interesting technical changes.

First, the Arke has integrated the coloration process (ink-jet printing) directly into the same mechanical systems as the cutting and gluing processes. The new ink-jet head (made by Funai, one of the world’s largest ink-jet companies, who owns the Lexmark brand you may have heard of), is of much higher resolution at 4800 x 2400 DPI.

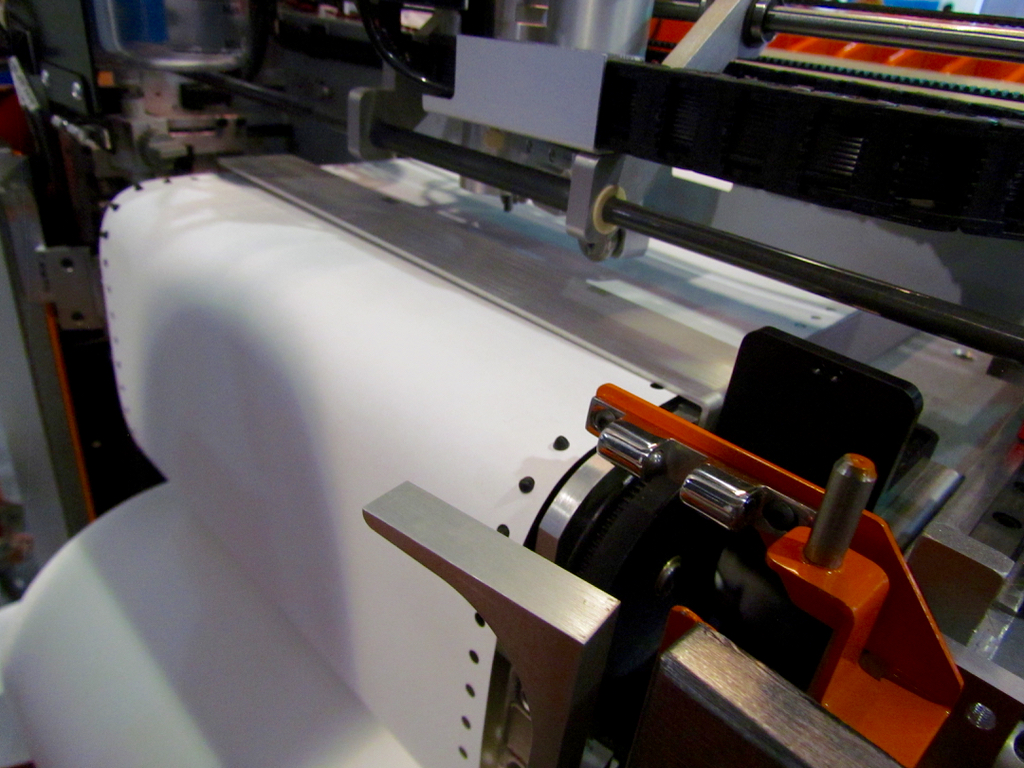

The second major change is with the materials used. Yes, it’s still paper, but instead of using commonly available paper sheets, the Arke uses paper rolls! These rolls are fed in by sprockets shown here. The reason for this change is that the paper can move at a far faster speed, and is registered to the same location in the print chamber at very high accuracy.

Another change with the paper is that you must now purchase the specialized paper rolls from MCOR. The reasoning here is not to gouge the customers on materials (the rolls are expected to cost only around USD$15, or maybe even less). Instead it’s to maintain color quality and adhesion properties, which would otherwise vary depending on what kind of paper sheets are fed in by customers.

The sprocket system is also significantly more reliable. Consider an analogous system: the ubiquitous paper receipt printers we see everywhere. They always work, and so should the Arke. The same style of paper mechanism is used in very high speed paper printers, too.

One curious feature is a machine-wide color band that appears on the front of the Arke. It’s under program control by the machine itself, and it is used to display status. Specifically it’s a giant progress bar that can be seen well across a room.

Why make such a strange feature? The answer is that when used in the classroom, students and teachers will be able to quickly see when a job is completed.

Of course, this machine is quite wired as well. It includes WiFi, Ethernet and two USB ports (front and back). The camera used in the Iris has also made the jump to the Arke, but instead of being designed for maintenance service, the Arke’s cameras are specifically set up for viewing the print operations, which can be done from a new MCOR app remotely. The app also permits operational commands can be sent to the machine. MacCormack also hints that this machine could even order its own supplies in the future.

For the first time in MCOR machine history, the Arke includes a color touch screen on the front of the machine. It’s not as large as some we’ve seen, but we suspect the Arke will be normally operated from the App. Interesting feature: you can see a 3D preview of the current print on this screen.

The gluing system is quite different, although you won’t see it unless you dig deep inside the machine. It’s a kind of strange “dragging” mechanism that tags along with the cutter. But the implication is that the Arke can now do “vectored” cuts and gluing, whereas the Iris could not. This implies much faster prints and far smoother surfaces. There’s also a new adaptive system that simplifies the waste material removal that should permit printing of even more complex objects.

Another very unusual feature for an industrial 3D printer is the ability to select different “skins”. Yes, there are three different case styles for the Arke, including White, Gray and Woodgrain. Perhaps there will be more in the future.

Let’s look at the bottom line here: the Arke produces far superior fully color textured objects at a speed of around 10-12mm per hour.

But the most interesting feature, which we haven’t mentioned yet, is the price: USD$8,995. This is significantly less than the Iris, which was priced around USD$50,000, and the only other fully RGB-capable 3D printers from 3D Systems’ ProJet line. Combining this low entry price with the price of materials means you have a winning combination of reliability, price and color.

How did MCOR get the price so low? Evidently during its two-year development cycle, their engineers were challenged to build a low-priced machine. For example, the Arke includes only stepper motors, whereas one of the servo motors in the Iris cost as much as ALL of the steppers in the Arke. It’s that kind of intelligent design that brings the price down.

While there have been apparently 2,572 pre-orders from MCOR resellers in anticipation of demand to the tune of USD$22M, they will have to wait until mid-2016 when the Arke is released. This machine may well change everything for MCOR. According to MacCormack, they’ll be selling thousands of machines instead of hundreds.

Via MCOR