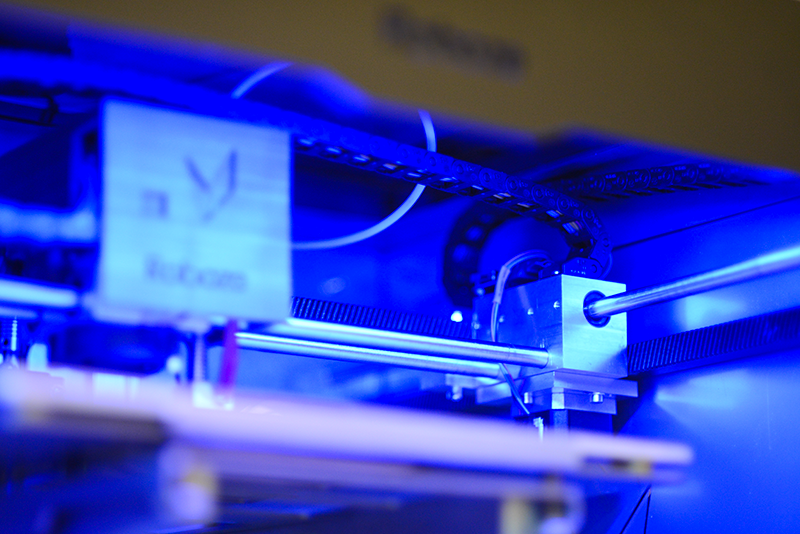

We’re checking out a new desktop 3D printer, the Roboze One+400, which claims to use no belts within its motion system.

Instead of belts, which are commonly used by virtually every other desktop 3D printer, they use a rack and pinion system. A “helical rack” is directly contacted by a pinion to drive both the X and Y axes on this machine.

There are several advantages to this approach:

- Flexible belts by nature have a bit of “give”, and this translates into lowered printing accuracy, while the direct-contact rack and pinion system should have no “give”. Expect few wobbles and higher printing accuracy

- Belts often wear out, break or worst of all, stretch. Stretched belts lead to poor printing results as the motion becomes less accurate, and sometimes steps are skipped if the loose belt slips off the driving gear. These types of errors are far less likely to happen in the Roboze One+400

- Print speed should improve. Indeed, Roboze explains that their machine can hit speeds of up to 250mm/second while printing, which is quite fast

But, there may be a disadvantage:

- If the rack and pinion system does break down, perhaps due to a printing error that jams some plastic in the works, repairs could be very costly

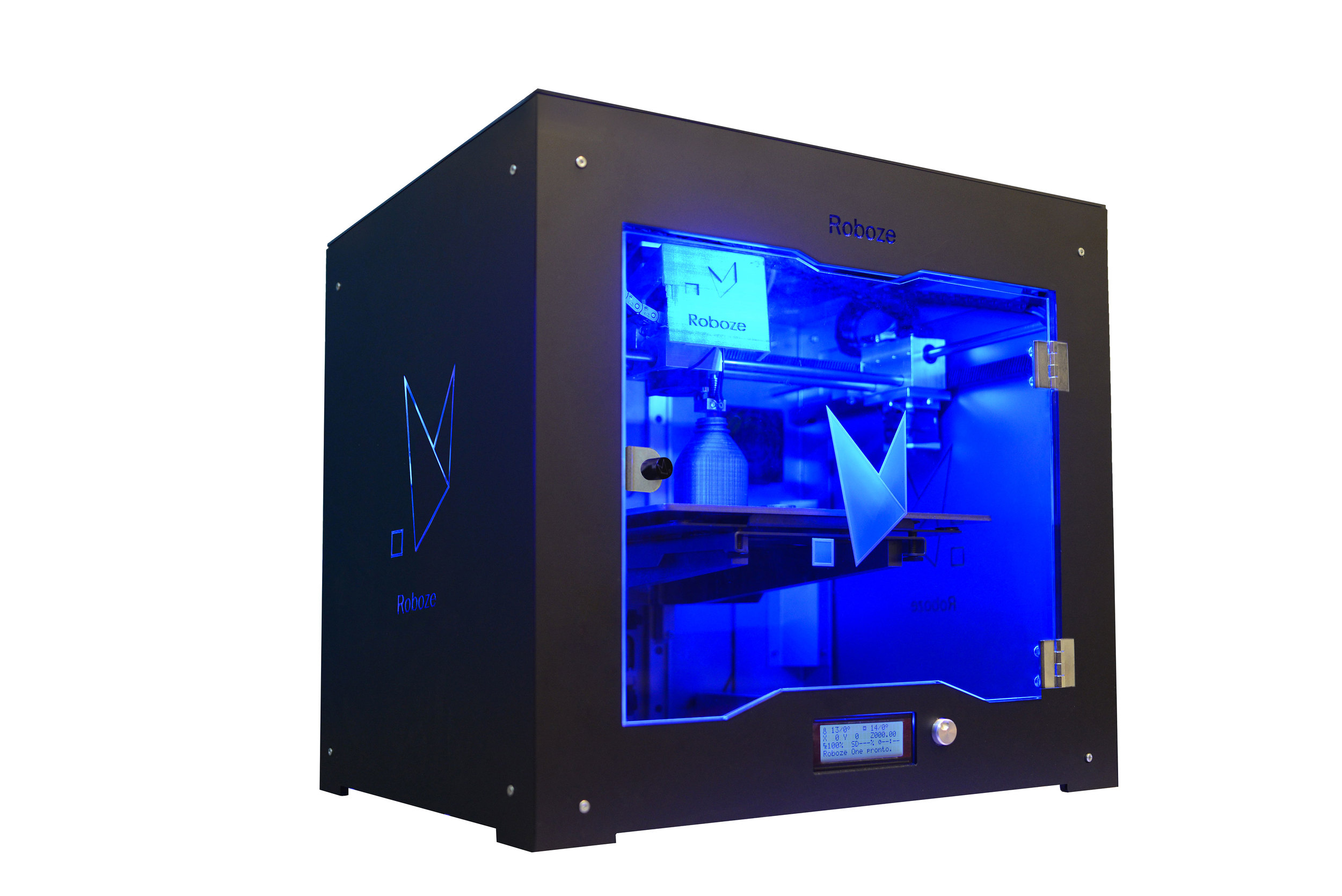

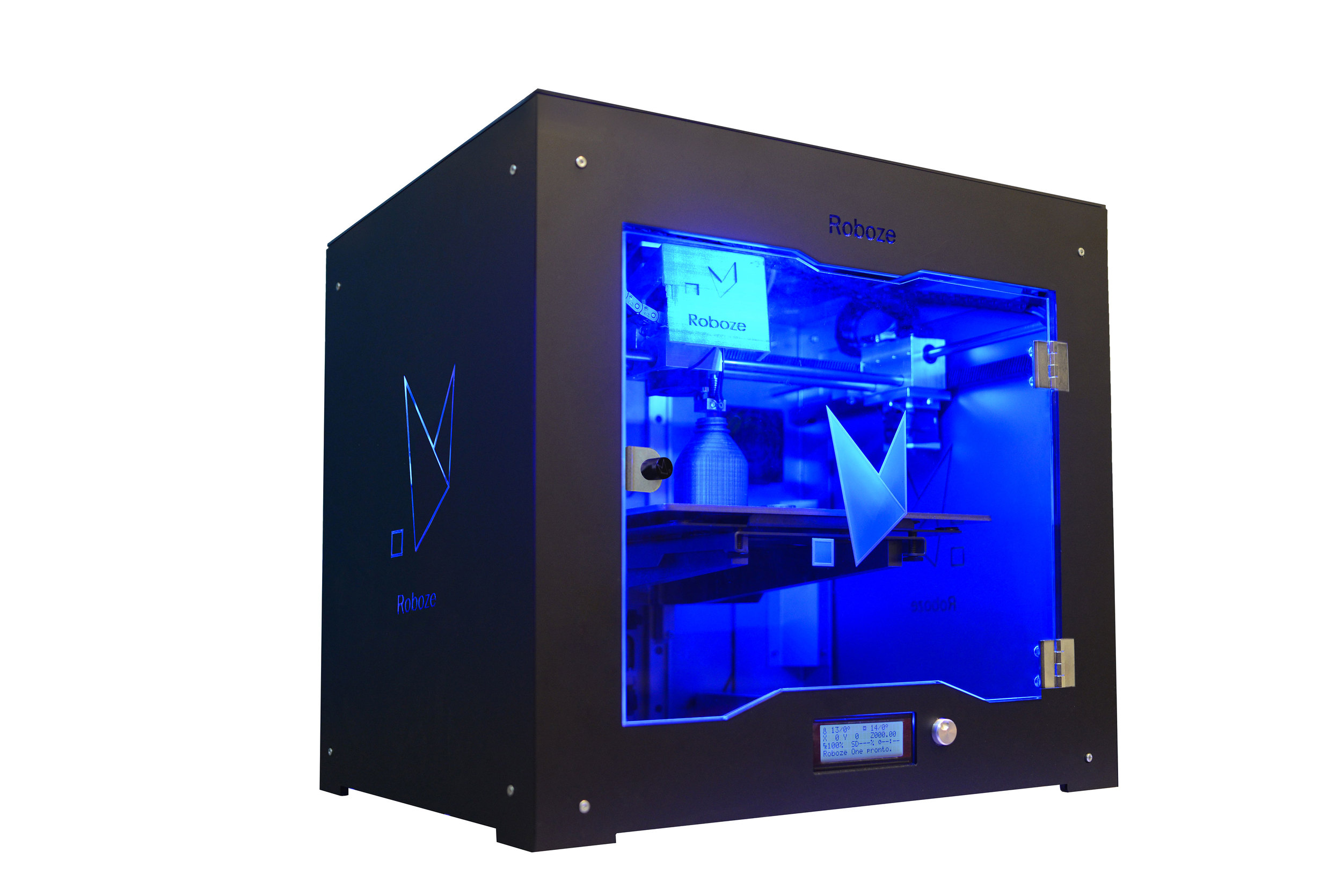

Aside from the mechanical system, the Roboze One+400 appears to be a competent plastic-extrusion style desktop 3D printer. It’s generous 280 x 220 x 200mm build volume should accommodate reasonably large and lengthy prints, and the innovative mechanical system likely reduces the probability of error during such long duration operations.

A heated print surface ensures that a wide variety of plastic filament materials can be printed in the Roboze One+400. Even better, the machine, as you can see in the image at top, Roboze builds machines that are completely enclosed, enabling heat capture for more reliable printing of warp-prone materials, like ABS.

Curiously, the filament spool is held inside the case, unlike many other machines. The idea here is to protect the filament from contamination by dust and other unwelcome material in the environment surrounding the 3D printer. Dust can accumulate in the nozzle over time, resulting in clogs and jams.

However, the internal spool holder does present some size restrictions on the spools you can use with this machine. For example, you will not be able to use some of the newly offered high-capacity spools in the 2-5Kg range. It’s possible the Roboze One+400 can use an externally-mounted spool, but we haven’t seen an example of this yet.

The Roboze One+400 is actually a new model that’s expected to be released this April, and it’s new feature is the extruder. There will be dual extruders, both capable of hitting a high temperature of 400C, meaning this machine will be capable of 3D printing exotic plastics such as PEEK, PEI and Polycarbonate and even ULTEM.

We’re not certain of the price for the new Roboze One+400, but it will surely be known when the machine launches. We anticipate a relatively higher price for this model, as it includes some very peculiar features that are mostly applicable to professional engineers and designers who usually occupy the higher-priced market.

Via Roboze