A new style of 3D printer filament is being developed by Adam Beane Industries that will enable you to post-process your print by sculpting.

Adam Beane Industries is a firm that specializes in sculpting materials. They’ve developed two “premium” materials, Cx5 and Cx5s that are specifically made for sculpting. They explain them in this way:

Cx5 and Cx5s are premium sculpting materials designed to be used in place of sculpting clays, finish waxes, and prototyping plastics. They handle like clay when warm, finish like wax, and can be as hard as plastic when cool. Cx5s is the softer version, and by mixing the two you can create a hardness level that’s appropriate for your sculpting style. They are the ideal material for every stage of your project, from roughing out and building up, to adding fine details, machined features and a high polish.

This is pretty amazing stuff. For example, it “never dries out or cracks”, and has “superior finishing properties to modern waxes”, “non toxic”, and “Machinable at low speed” and much more. Full details are available at the Adam Beane Industries site below.

But now we’ve learned that the company is working to transform this material into a 3D printer filament.

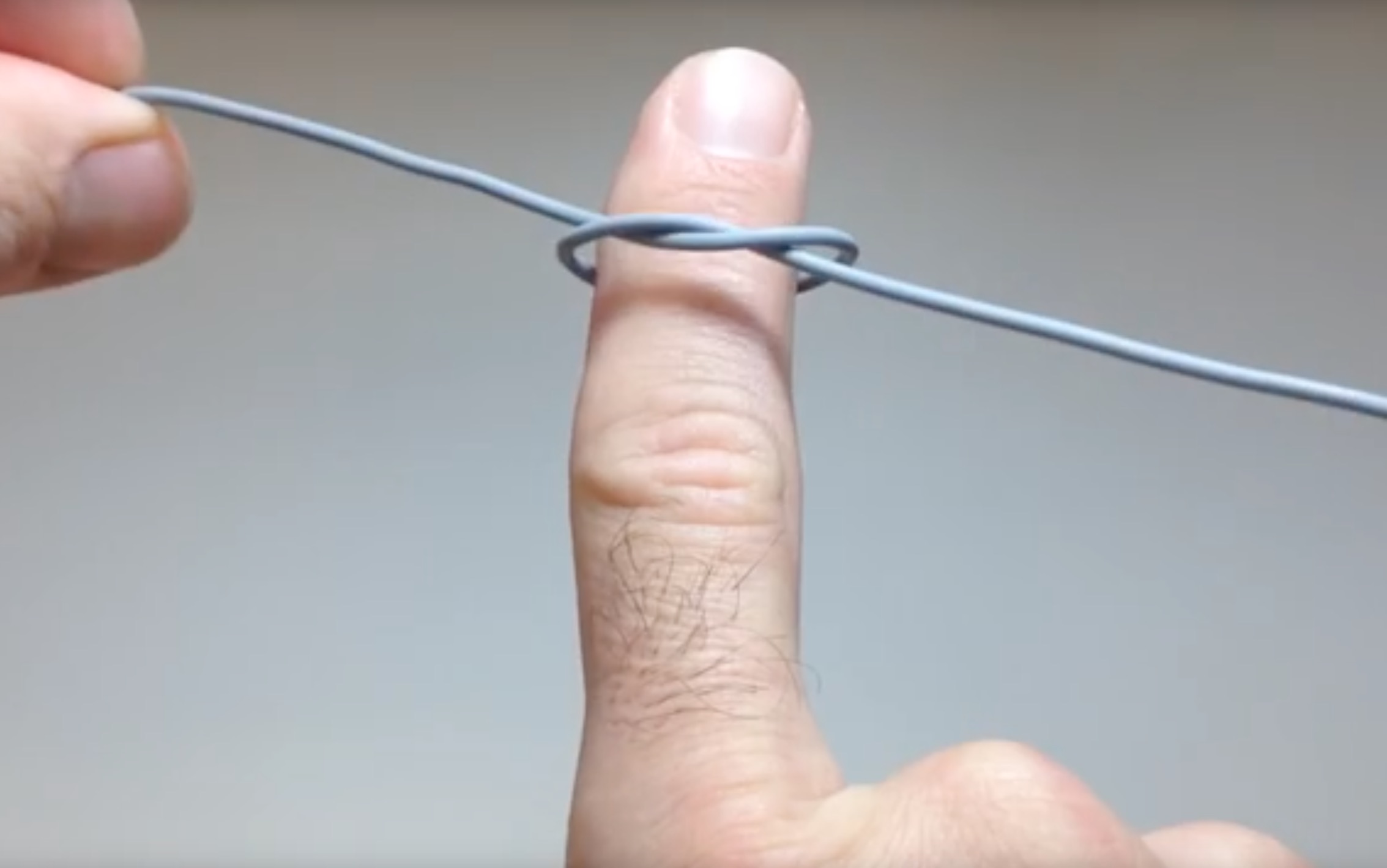

Now, you may be asking, “why is this a big deal?” The answer is found in the video. Just watch this:

Yes! You can easily smooth and engrave the printed surface. There’s no need for hot tools to dangerously carve off unwanted pieces of your artwork; instead you simply sculpt as you would a piece of clay.

Currently their site sells only blocks of Cx5 and Cx5s at USD$24 per pound (or about USD$53 per kg). They are not yet selling the filament shown in the video, but one would expect the price to be somewhat more than USD$53 per kg, perhaps priced like other premium filaments at around USD$80, if we were to speculate.

The new filament will clearly be a somewhat flexible filament, as seen in the video. This means it may not be compatible with all filament-based 3D printers, as some have lengthy material paths through which flexible filaments cannot be pushed. But we’ll find out more when they release the product.

So far we’ve seen specialty filaments developed most often for engineering purposes: extra strength, durability, etc. Now we have a specialty filament designed for artists, too.