Startup Carbon3D, inventors of the CLIP 3D printing process, just received no less than USD$100M in investment, leading TechCrunch to declare this will make 3D manufacturing a reality. This is misleading.

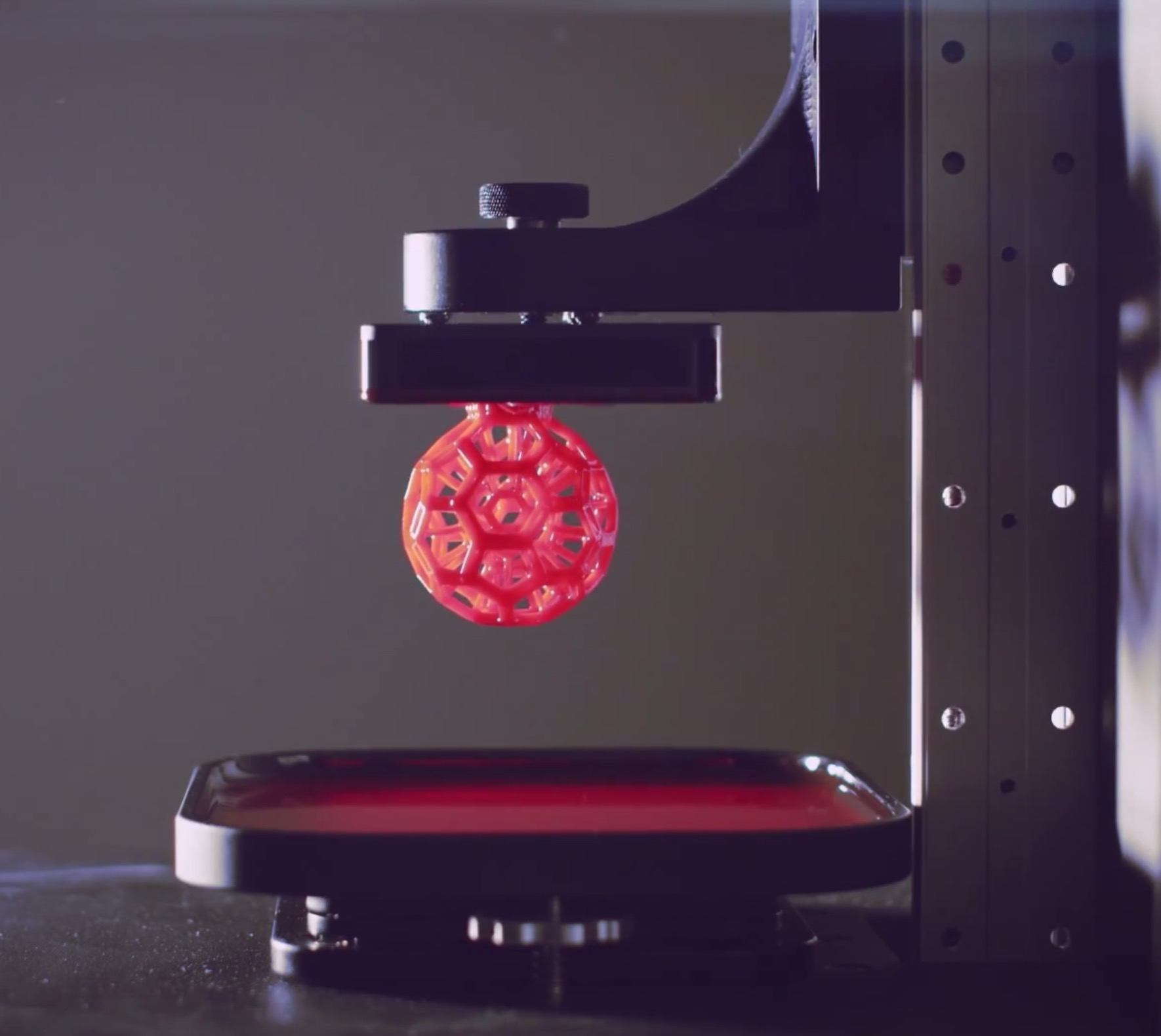

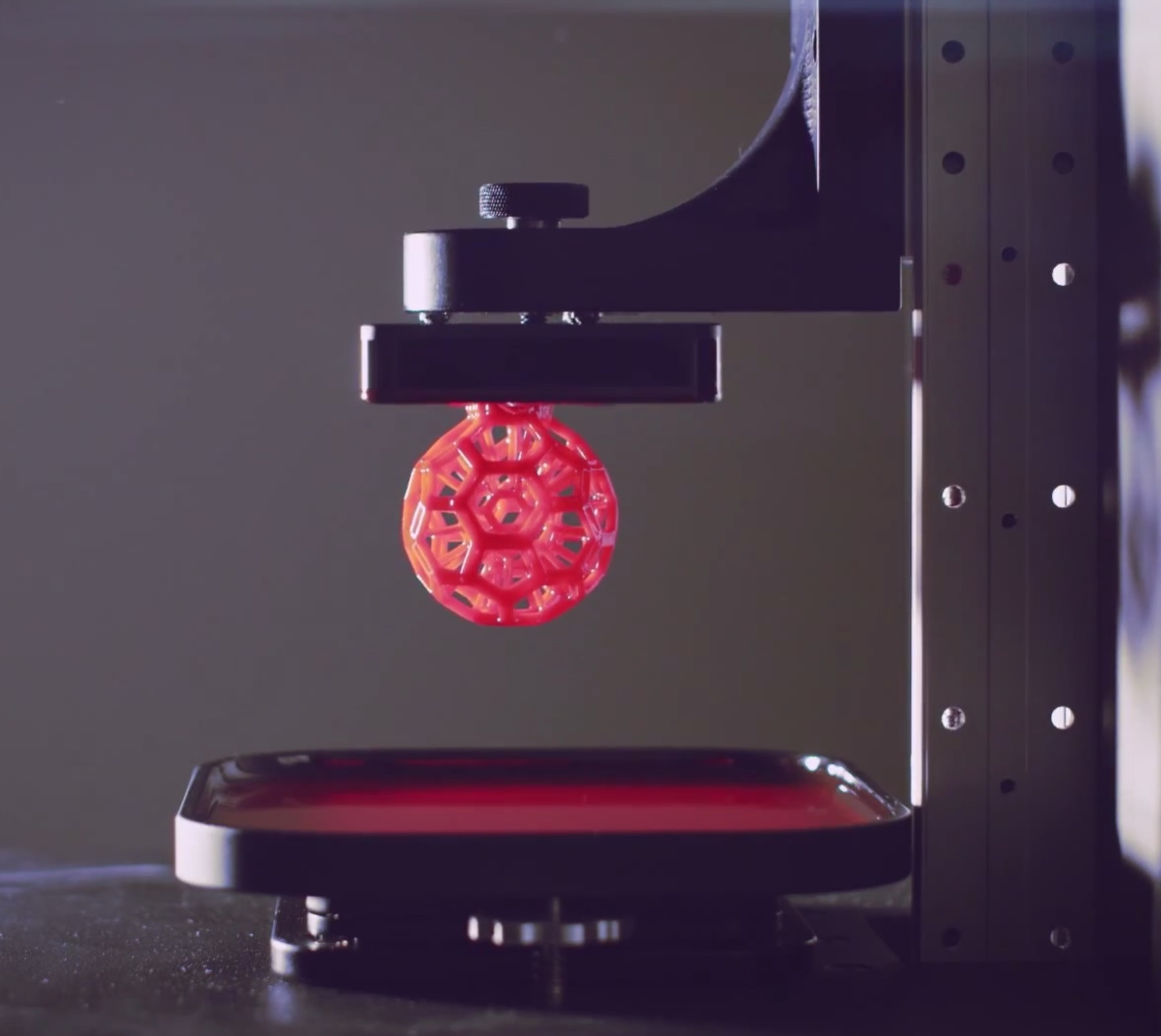

The Carbon3D process is an advancement over existing SLA resin-based processes. It provides a means to 3D print certain geometries at a faster pace because the machine does not have to slowly peel newly-solidified layers off the bottom of the resin tank. Depending on the specific geometry of the piece being printed, the print speed can be much faster.

The investment community has seen promise in their approach and have raised an additional USD$100M for the company, who had previously raised additional amounts. At this point, Carbon3D has sufficient funds to do whatever they require, and this round vastly increases the overall value of Carbon3D.

Techcrunch says:

Carbon3D, a startup building 3D printers for manufacturers, has pulled in $100 million in new funding to move 3D printing out of the prototyping phase and into production.

This is so untrue. Many companies now use 3D printing as a production process, particularly for low-volume, high-cost critical parts. Airlines and spacecraft are now using metal 3D printing for their components on a business-as-usual basis for some time now.

While there is still plenty of prototyping using 3D printing, there is a lot more production happening. We even wrote on a company that specializes in low-volume 3D printing for production, Xometry, last week.

We’re still awaiting announcements from Carbon3D that describe their product in more technical detail – and the types of markets and applications they see for their new process.

Via Techcrunch