At this time, most sellers offer 3D printer plastic filament in spools weighing 500g to 1kg. But perhaps these sizes are too small.

Why do we think so? It’s simply because there’s an increasing number of large-scale 3D printers commercially available, all of which can use generic plastic filament. There are, of course, large size industrial 3D printers, but these often use proprietary filament canisters. We’re not talking about those here.

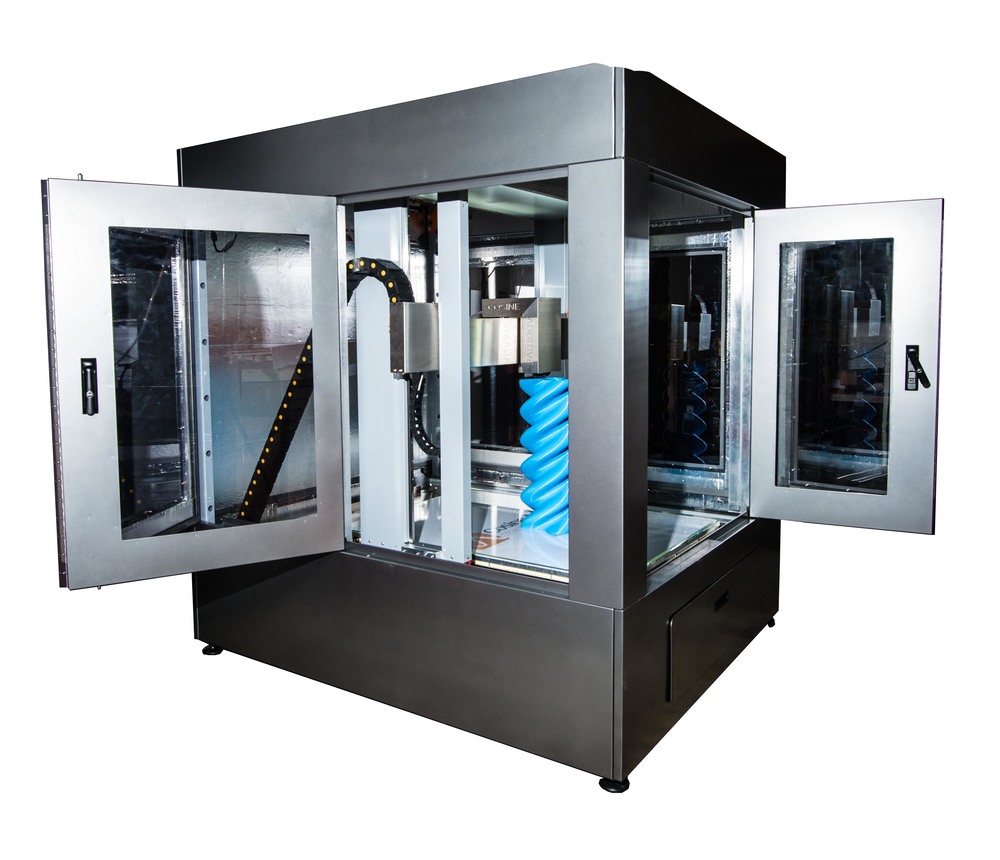

We’ve now seen several ultra-large 3D printers emerge, including those from BigRep, 3DP Unlimited and most recently Cosine Additive. Each of these machines has meter-sized build volumes.

And when you have extremely large build volumes, you print large things in them. Large things require a lot of plastic. More than 1kg in many cases. Thus, operators of these monster machines must carefully watch them and swap spools at the right moment to continue printing.

But wouldn’t be much easier if the machines could run (more or less) unattended during these long prints? One way to help that happen is to increase the size of filament spools.

Imagine, a 10kg spool would permit a large machine to operate for ten times longer. Given that a large component of the cost of operating a 3D printer is labor, this is a good thing. It’s also likely the per unit cost of larger spools will be less than today’s typical spool sizes.

It seems that Cosine Additive understand this, as they are apparently working on a massive 25kg (50 lb) spool for use in their machine. But here’s the thing: you should be able to buy such spools from the generic resellers in a choice of colors and materials. That’s not quite the case yet.

As the popularity and number of installed monster machines grows, expect to see larger spool sizes slowly emerge.

Image Credit: Monty Python Wikia