Those new to 3D printing get excited about the ability to print, but may be wondering about this thing called a “3D model”.

A personal 3D printer is indeed an exciting device, but it’s more difficult to use than it may first appear. While other household appliances are straightforward, a home 3D printer is a little different.

Typical appliances require adding some material or items (food, clothes, dishes) and the pressing of a few buttons to receive your roast turkey, clean clothes or plates. But a 3D printer is a digital appliance: you must supply it with instructions on exactly what to do.

This is the purpose of the 3D model. It’s a digital representation of a three dimensional object, much like a blueprint is a 2D representation. 3D models come in two species: CAD and Mesh.

A CAD model is, more or less, a sequenced series of basic steps and operations that lead to the desired 3D model. Imagine creating a CAD model of a bar of soap. We’d start with a plain rectangle of dimensions, say, 150 x 60 x 20mm, then bend it slightly in the middle to form the familiar curve of soap bars. We’d round the edges of the soap (a process called, “filleting”) to make it easy to hold. Finally, we’d emboss some lettering on the top by subtracting a string of characters from the surface.

The interesting aspect of a CAD model is that you can usually go back into the sequence and tweak the steps. In the soap example above, we could for example, just change the dimensions of the initial rectangle to produce a differently sized bar with all the remaining steps applied appropriately.

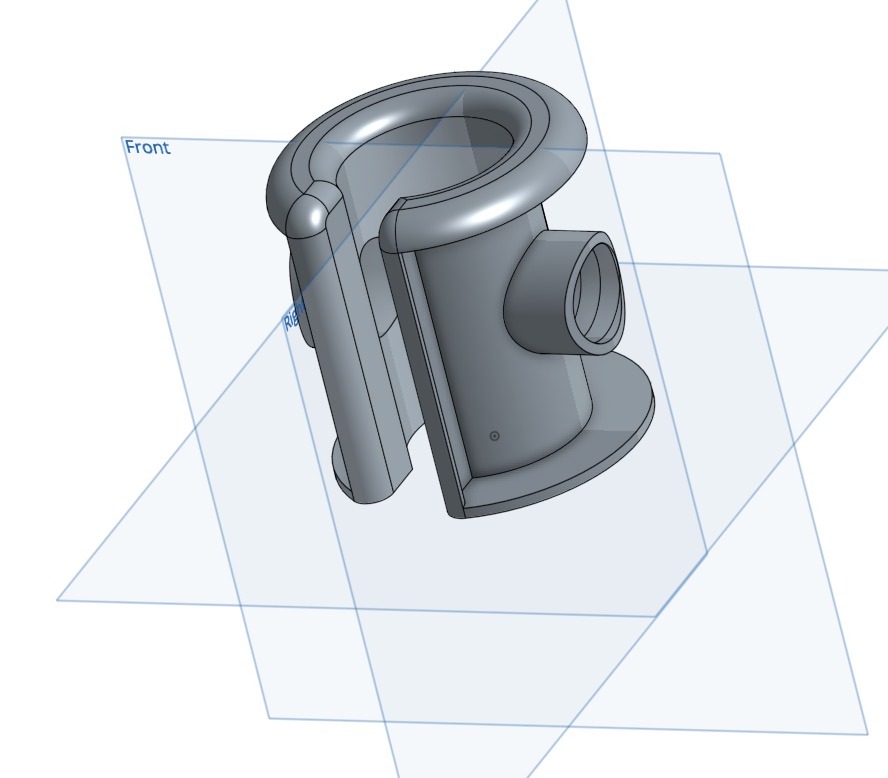

There are many different types of CAD file formats, some of which are incompatible with each other. Typically each 3D modeling program will invent their own, although exports and imports are sometimes provided. At top you can see an example of a CAD program showing the basic shapes combined to form a more complex object.

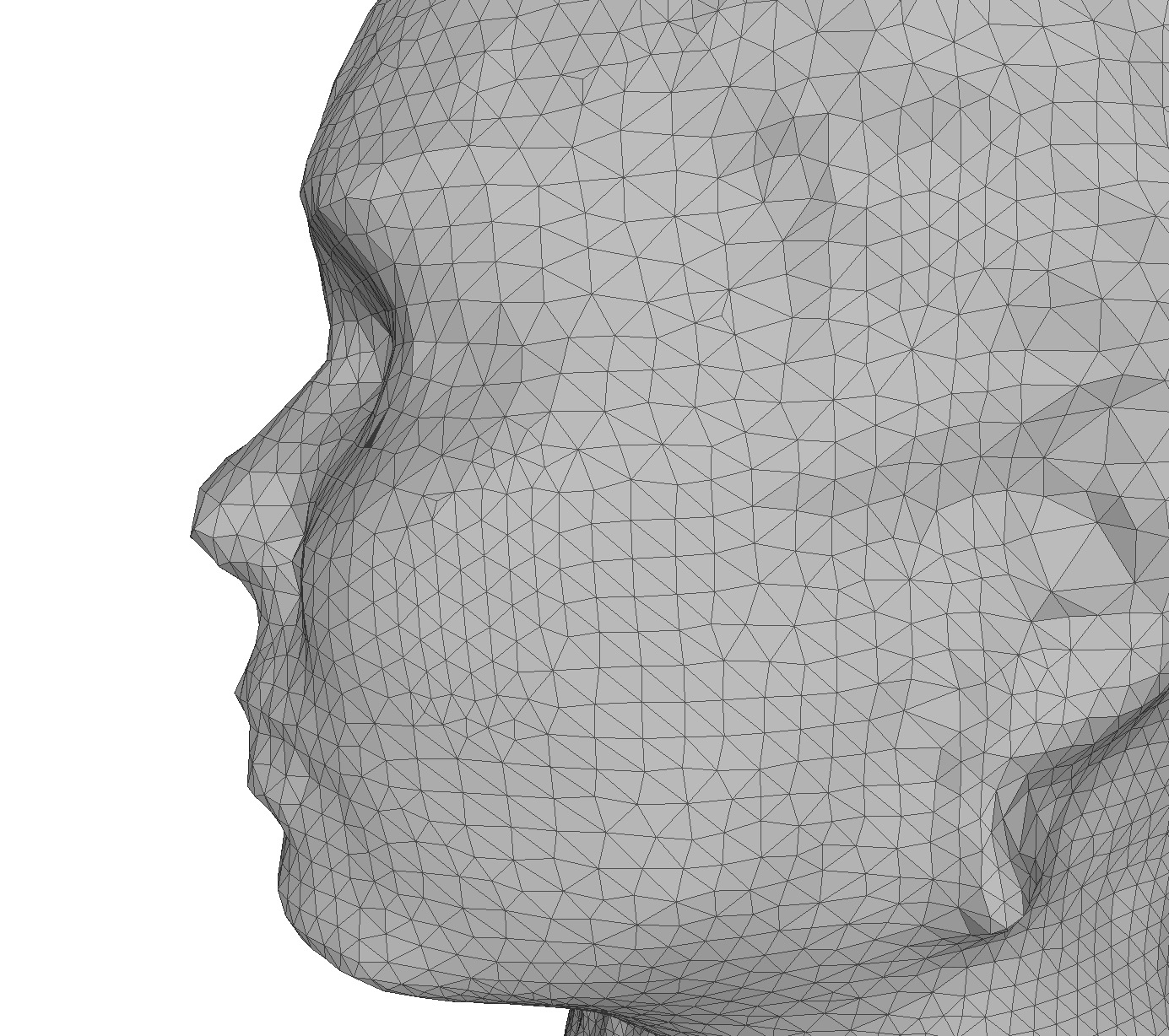

The other kind of 3D model is a Mesh, which is simply a representation of the shape of an object. It’s called a mesh because it is very much like tightly fitting a fishnet over all the exterior surfaces of the shape.

Here you can see how it works. In this example, a subject has been 3D scanned and transformed into a mesh made of triangles. It’s possible to use polygons other than triangles, but triangles are popular in the 3D printing world because that’s what the STL format uses. Other mesh formats may use different polygons.

The disadvantage of a mesh is that it’s not easy to change. If the soap bar example was exported as a mesh, perhaps in STL format, all you’d be able to do is move triangles around. You could not easily change the dimensions of the bar, as you would if it was a CAD model.

The advantage of STL is, of course, the ability to 3D print, since virtually all 3D printer management software will accept STL files for printing.