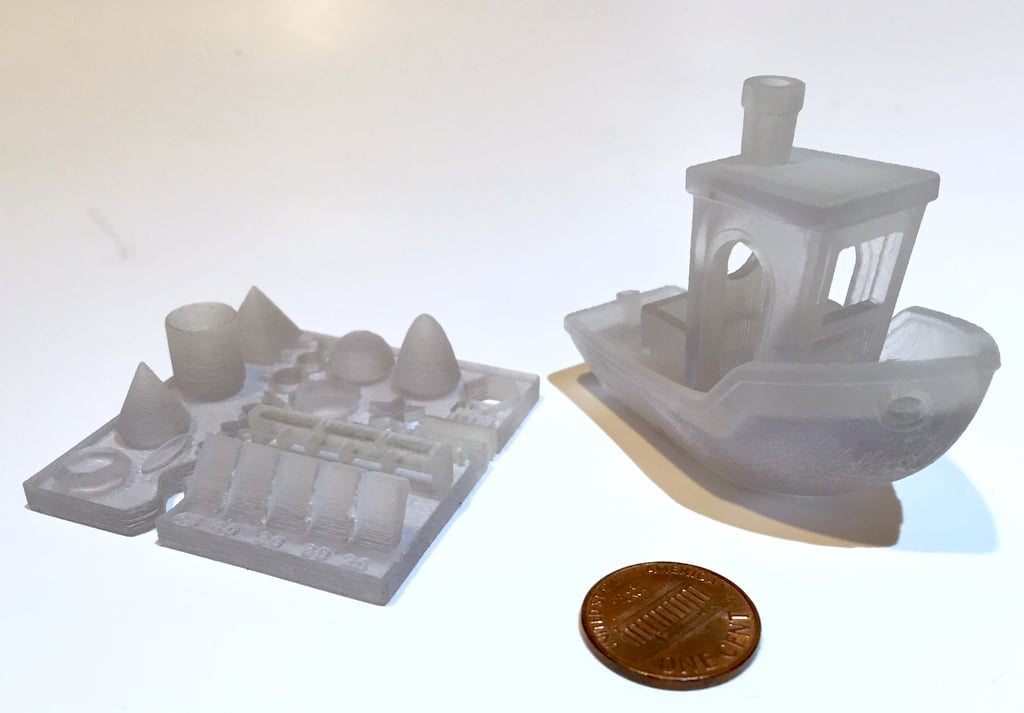

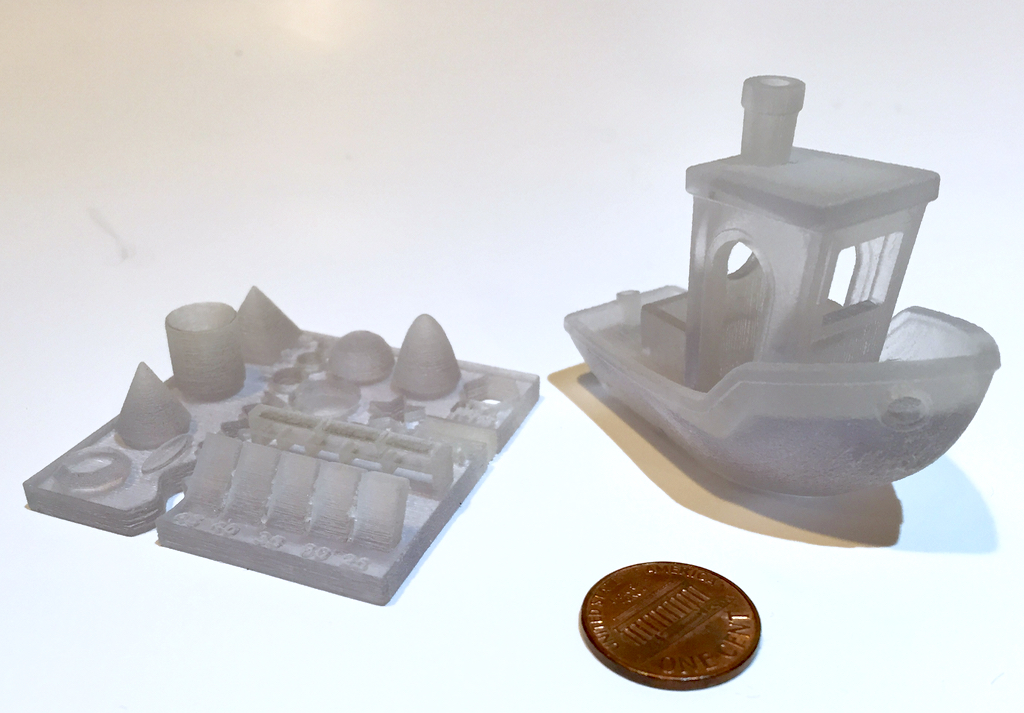

We 3D printed two popular benchmark 3D models on a top quality industrial 3D printer, the Stratasys Objet Connex260.

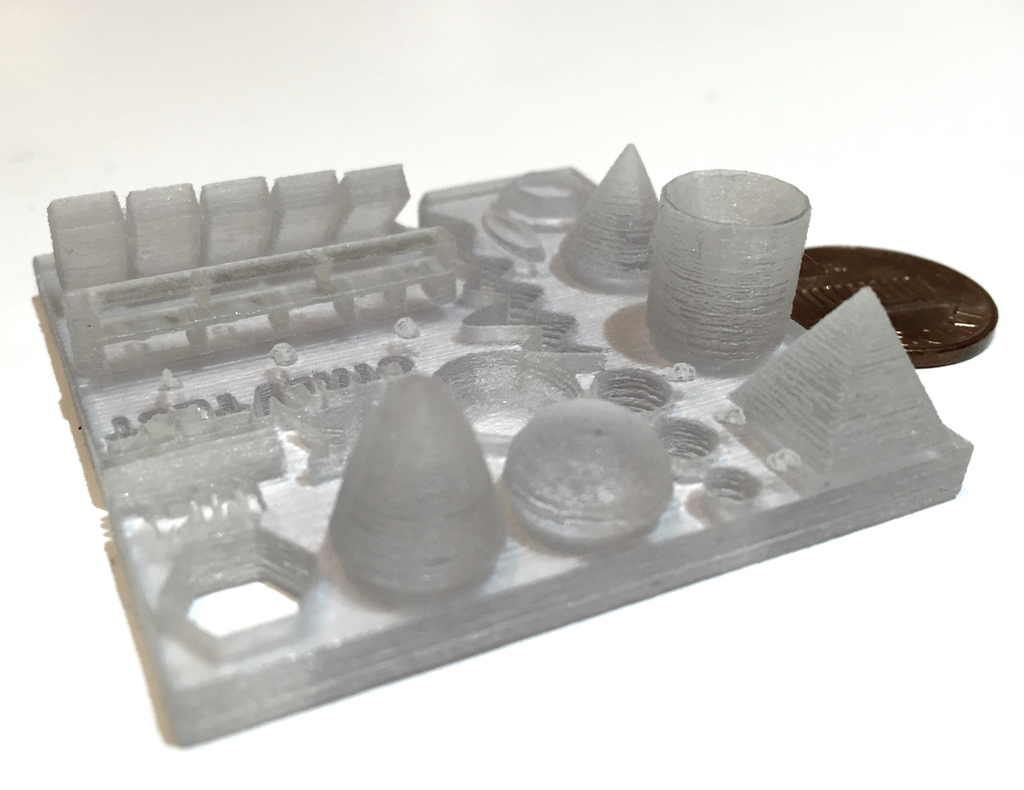

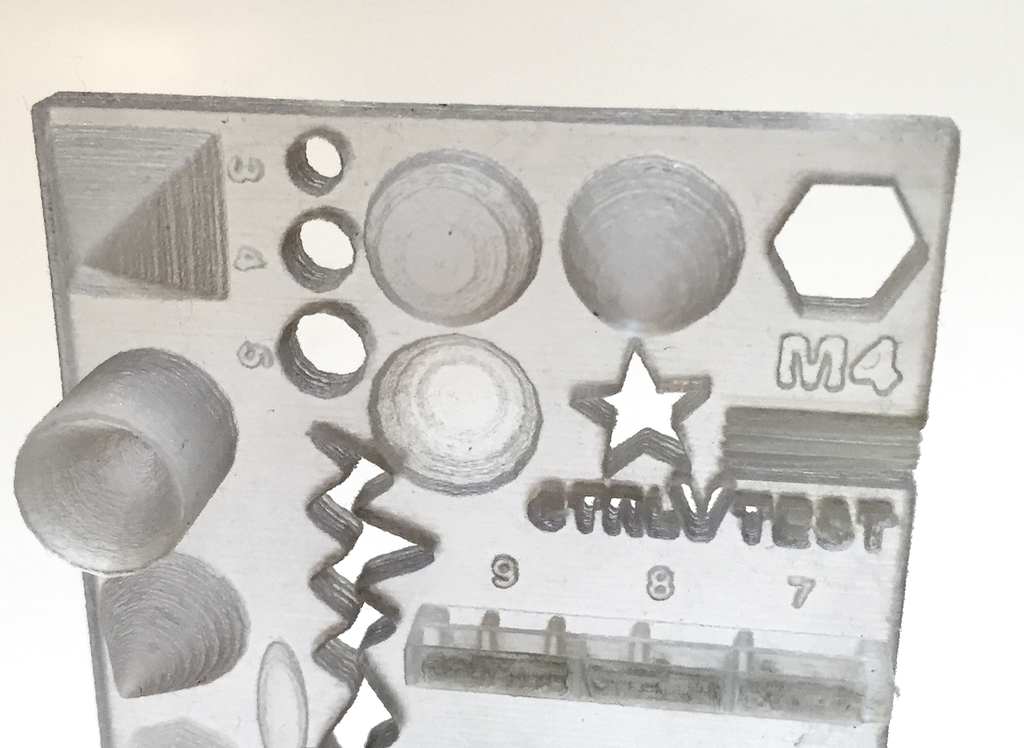

One of the two benchmarks we most frequently use when testing are the CTRL-V test, which is a small square object covered with a myriad of pathological geometric shapes that can baffle almost any 3D printer, including curves, bridges, fine printing and various protrusions. Print this item and you’ll soon see what your 3D printer is made of.

The other benchmark we prefer is #3DBenchy, a whimsical boat shape that also exhibits many challenging geometric properties, albeit not quite as extensive as the CTRL-V test. But it’s more fun. We have collected a great many #3DBenchy boats at our lab.

Normally, printing these two items on a desktop 3D printer will fail in some manner. Perhaps the bridges will slump, the surfaces are irregular or the lettering will be unreadable. It’s pretty difficult to get a perfect print, even on a finely tuned plastic extrusion 3D printer.

But what would happen if you printed them on a very expensive industrial 3D printer? We just happen to have one in our lab: the Stratasys Objet Connex260, a machine capable of printing very high resolution objects in pretty strong material.

For our test prints, we selected Objet’s VeroClear material. Well, actually, that’s what happened to be loaded in the 3D printer – and on these machines you do not want to frivolously change the material. Why? Because resin changes result in a pretty expensive system flush to prime the plumbing with the new resin, often costing several USD$100’s to do so. So, VeroClear it was.

The prints were printed at 0.031mm resolution, which is not the highest achievable by the Connex260. For that, you must load both resin slots with the same material; we were unwilling to do so for the reasons above.

The results were spectacular, as this is “clearly” the best #3DBenchy we’ve yet seen. This boat was printed on its side, unlike typical plastic extrusion prints, so the layer lines are a bit unusual. The print is near flawless.

Here is the CTRL-V test, showing the incredible detail achievable by the Connex260.

A close-up view shows more of the detail possible on this machine. You can see very clearly defined lettering and crisp cones on the left.

Some of the cavities are not quite as crisp as they should be, simply because we were a bit lazy cleaning the print. You see, the Connex series of 3D printers covers all prints completely in gooey support material that must be cleaned off. This is normally done with a water jet, but in the case of the CTRL-V test, you have to use very small tools to scrape off the goo. So, the object is actually a bit better than it looks.

Are these the ultimate benchmarks? Probably not. We’re wondering if any readers might be able to try and beat them by printing them on a higher resolution machine. Just use the files below: