This week’s selection is Brian Matthews’ highly realistic 3D printed parrot.

The parrot is not something you’d confuse with a real parrot by any means, as it is clearly a manufactured object. However, the key to its success is in its subtle yet highly realistic movements. If not for the visible mechanics, you might believe this is an actual parrot.

Matthews is an “engineer/artist”, who created the parrot using a variety of skills. The parrot is not merely 3D printed, but is composed of servo motors (seven), mechanical elements, an Arduino processor and software to run all the above.

The key is in the motion, which is largely derived from the software. According to Matthews, since 1998, he:

Has made 17 pairs of wings varying in materials and operation from simple pulley opening to pneumatics and robotic control.

And has:

Taken an interest in Arduino animatronic programming in conjunction with custom 3-D printed parts to make interesting creatures.

With all that experience, it’s no wonder he’s managed to perfect the art of avian motion, at least for shoulder-mounted parrots.

Matthews told us the parrot was created as part of a “learning exercise”, and “for fun”.

What was most interesting to us was the process Matthews employed to create the parrot: The designs were created in SketchUp, while the printing was done on a commonly-available Afinia desktop 3D printer. The parts were a mix of ABS (for the “fuselage”) and PLA (for the wings).

This tells us that the key to success can often be the idea and not the equipment.

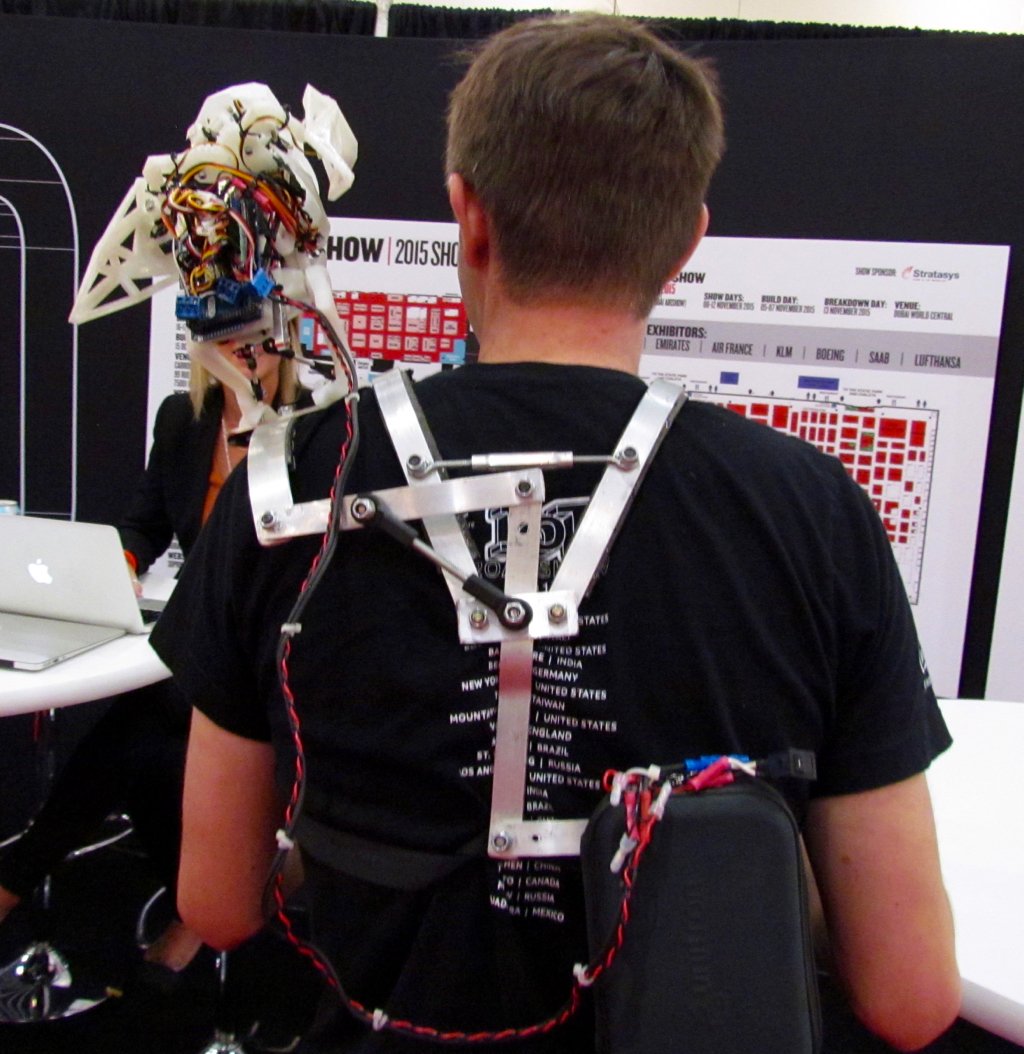

And the design is fascinating. While you may focus on the parrot itself, there is more to the story. Here we see a rear view of Matthews, exposing several important elements to the parrot. The computing power is held in the box at the lower right, and an adjustable shoulder mount takes spreads the weight of the parrot and computing box to make wearing the parrot more comfortable.

Can you purchase a parrot? We’re not certain, but it’s likely as Matthews is “available for commission work”.