There are many people today who have taken the personal technology step to acquiring their own 3D printer. But what happens when you need to do more than it can do?

3D printing today is as advanced as the technology has ever been. That said, the technology of 3D printing is not a complete manufacturing capability: there are many constraints on 3D printing, such as choice of material, size of build, cost of printing, speed of completion and more. While you can definitely make many things with a 3D printer, there are times when it’s just better – or even required – to make components with other manufacturing processes.

Consider the case where a metal component is required. One could 3D print a model of the component, and then use the lost-plastic process to cast it in metal, but your results may not be sufficiently accurate for your application. And you’re using another manufacturing process anyway. The result is that many people owning a 3D printer have very limited access to other ways of making things.

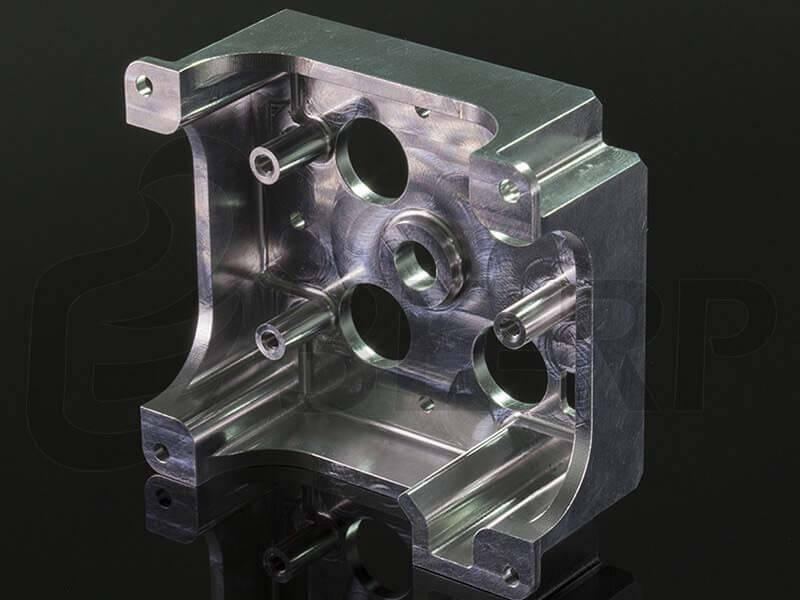

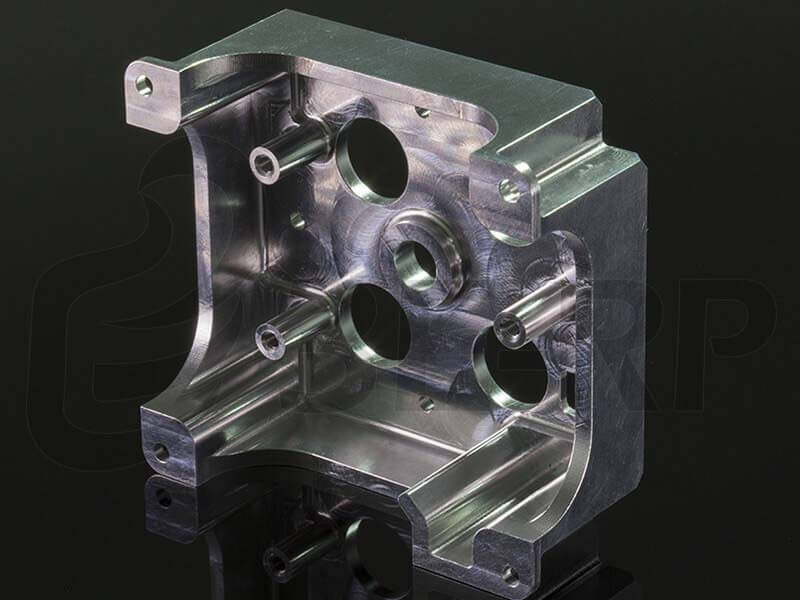

Even with 3D printed items, your application may require perfectly smooth surfaces that are generally not possible with most 3D printing equipment. For that you may have to resort to use of CNC milling equipment, which can produce surfaces with a polished shine.

What to do? If you’re lucky, you might have access to a friendly workshop or makerspace. If you’re flush with cash, you might consider building your own workshop, but that may not be the most effective use of money, particularly when you consider that you’ll have to learn potentially several other manufacturing processes to obtain good results.

Manufacturing organizations typically use 3D printers to produce prototypes, with very limited use in making production parts due the material and technical limitations of today’s 3D printers. To take these prototypes from a concept to a real, manufacturable product could involve multiple manufacturing processes beyond 3D printing alone that few companies have available on site. Engaging a fully-equipped manufacturing shop can help at any stage of this process to produce an efficiently manufacturable product.

One answer to this question is to seek out a local manufacturing firm equipped with the required machinery and expertise to do the job you’re not able to do yourself. However, in some cases this can be prohibitively expensive, as such workshops are often set up for much larger deals. This option may or may not work for you.

Another option is to seek out the services of an offshore manufacturing firm for your non-3D printing work, which may prove less expensive and with the same quality you require. There’s many to choose from, but one we’ve looked at is 3E Rapid Prototyping, based in southern China.

This company provides a wide variety of 4 and 5-axis CNC services, vacuum casting, pressure die casting, aluminum extrusion, sheet metal prototyping and multiple methods of surface finishing. They also provide several types of 3D printing services, too.

This is the critical point: making something complex often requires use of several different manufacturing processes, and it would be in your interest to engage with a single firm that provides all of them to optimize the costs of the engagement.

If you find your making capabilities inadequate for the project you’re working on, you might consider using the services of a company like 3E Rapid Prototyping.