A new company hopes to revolutionize making by enabling circuit printing with a 3D printer.

Voxel8’s new process is intended to enable inventors to print increased function machines by embedding electrical circuits inside printed objects.

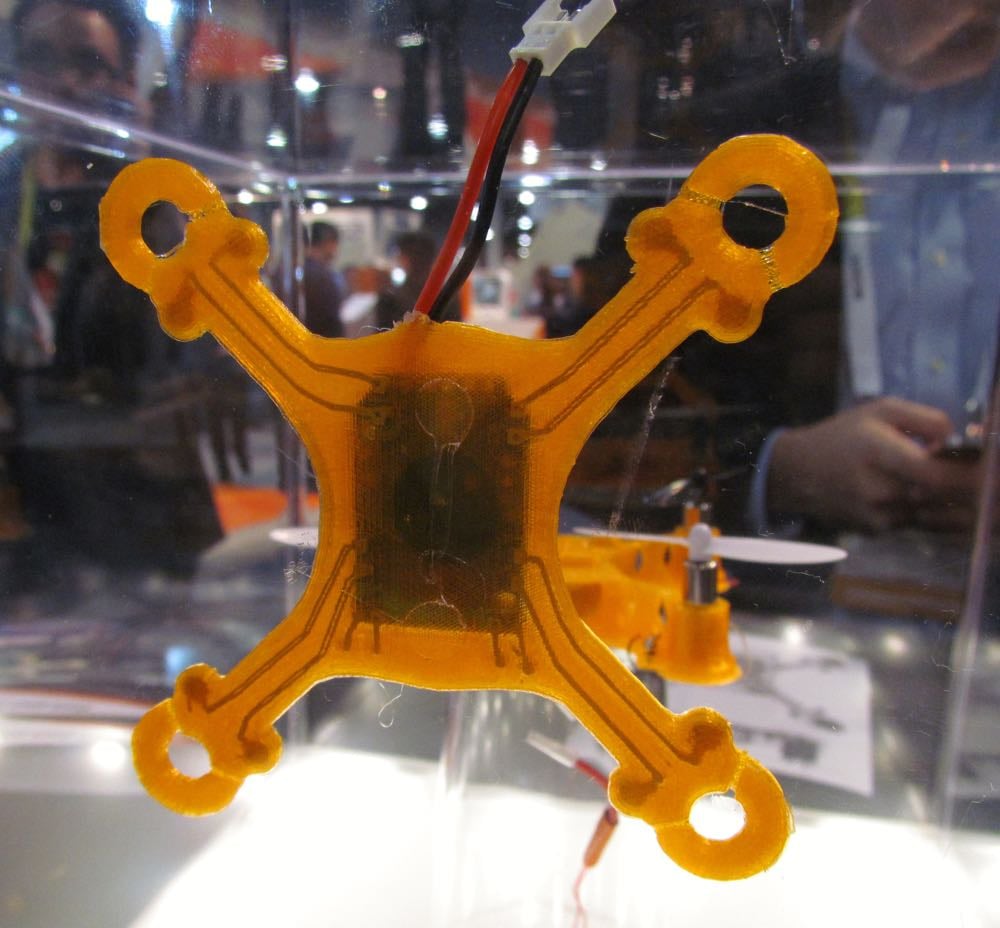

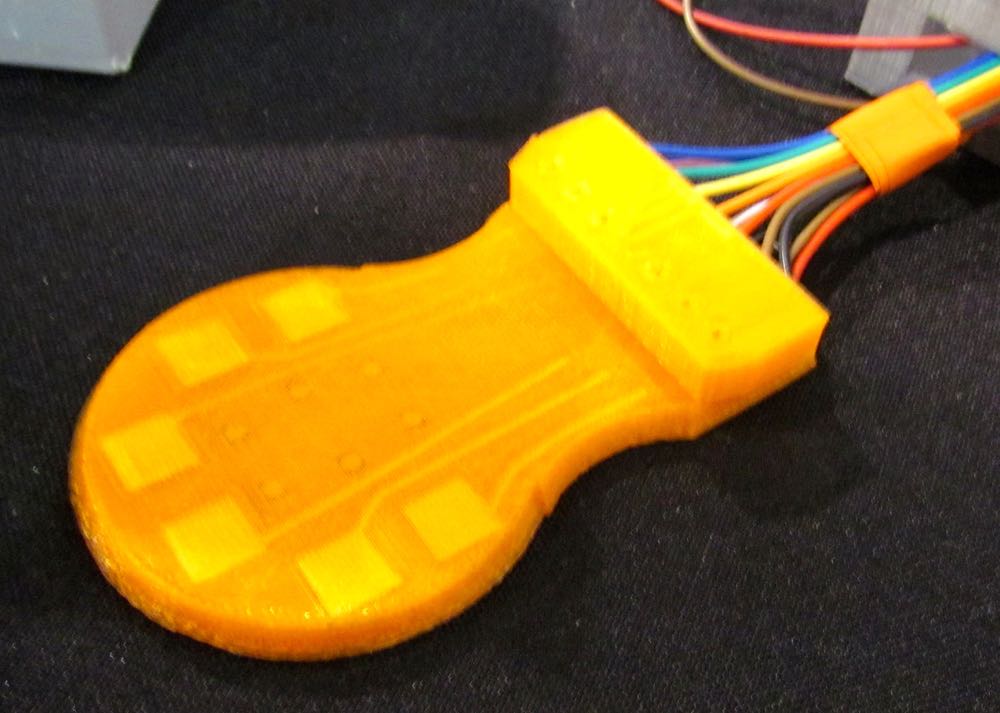

The company, which emerged from the materials science world, began by inventing the conductive paste around which the rest of the system is designed. It’s a conductive silver ink that’s printed via a pneumatic process. In other words, it’s carefully squirted onto the current print layer with a syringe-like mechanism.

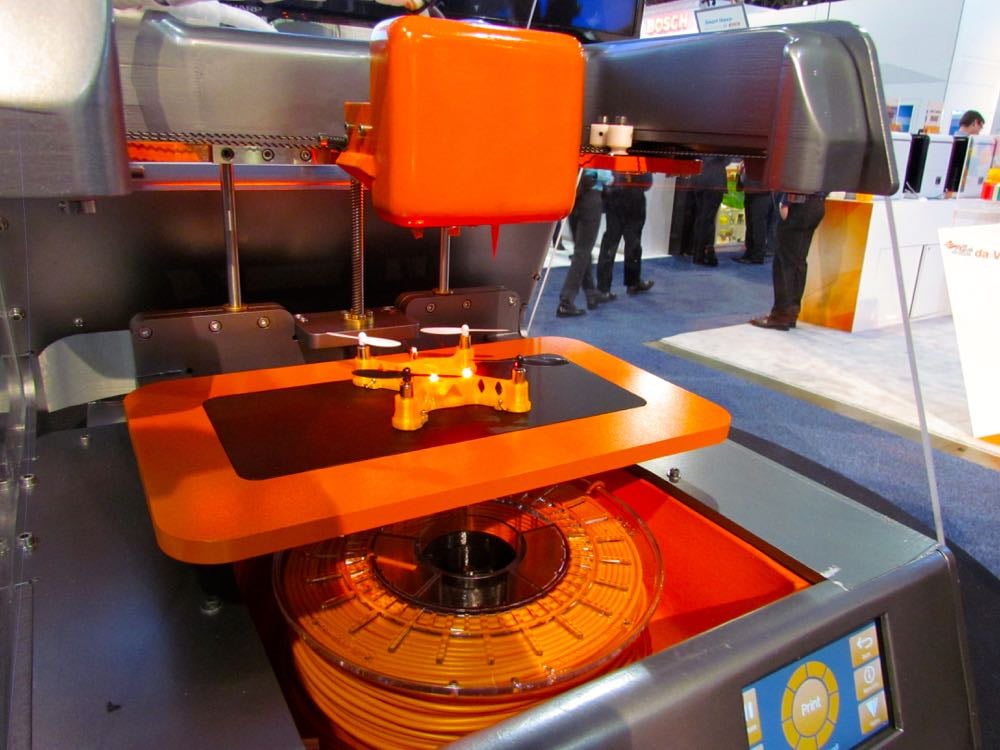

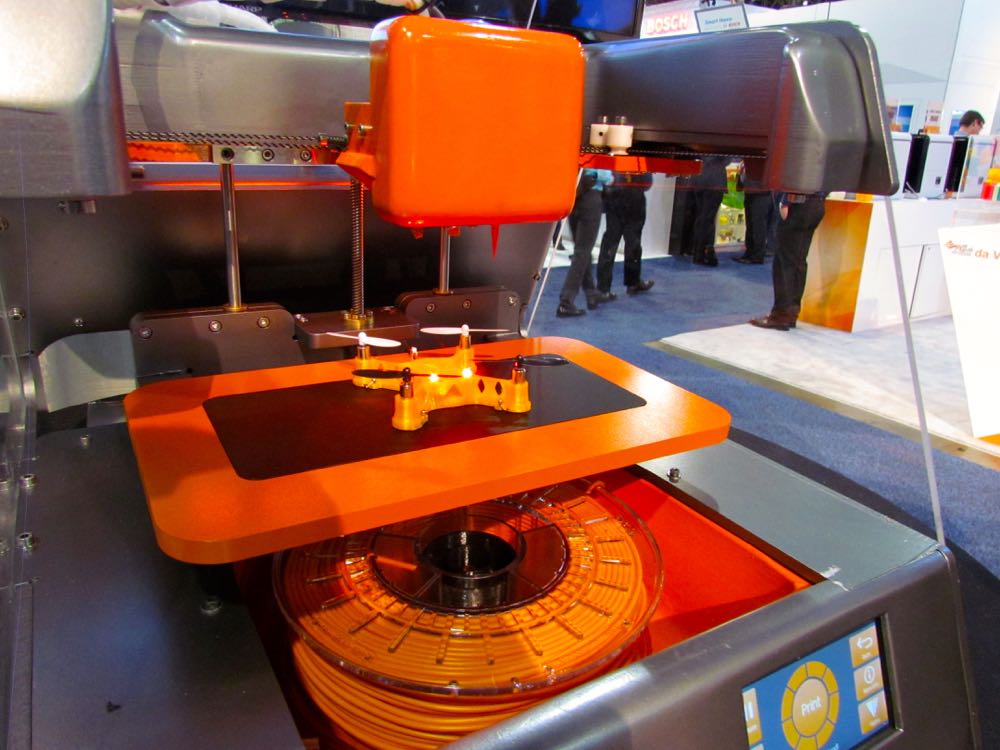

In their development printer, the pneumatic extruder is paired with a conventional PLA extruder to form a powerful making machine. A 3D plastic object can be printed, but conductive traces can be embedded within the 3D object – and in three dimensional paths, too. With an appropriate design, one could, in a single operation, 3D print a machine that would need only have an electronics board dropped in to complete the assembly. The board would contact the embedded traces and negate the need for hollow channels in which to place wiring.

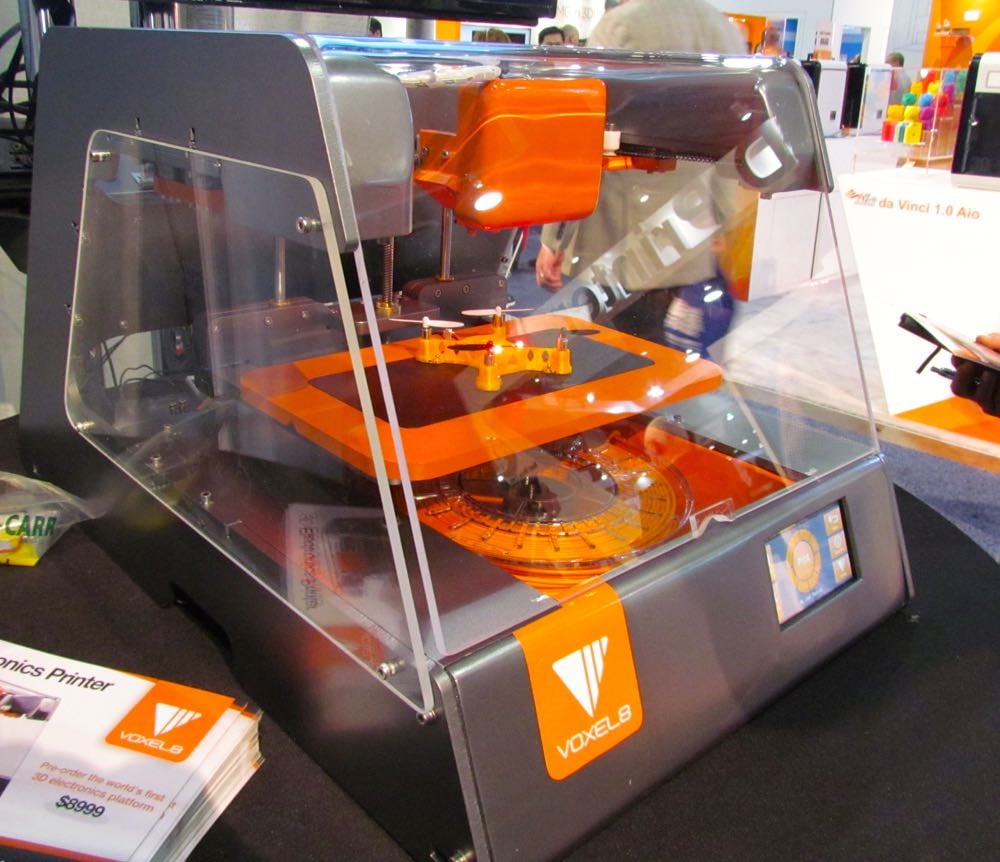

The company has used the process to print a variety of interesting devices, such as this working quadcopter. The process not only simplifies the making process, but also enables new structures not easily made with other processes.

As you might imagine, there’d better be software ready to assist designing such hybrid plastic-electrical objects. Voxel8 has been working with Autodesk to develop said tool. We confirmed with Voxel8 that it is not Autodesk’s existing 123D Circuits tool, but something different and new.

The printer itself is fairly standard, with a couple of exceptions. It prints PLA in layers as small as 0.2mm within a 100 x 150 x 100mm volume. It includes both USB and WiFi connectivity and printing can be observed from three sides. The build plate also includes an auto-leveling feature.

The differences include, of course, the pneumatic conductive trace printing capability, but also a magnetic bed that is easily removed during print pauses for component insertion. Replacing the bed for print resumption guarantees it is in exactly the same position. The conductive paste is provided in specialized cartridges that are easy to install. We got the impression they intend on developing additional making materials that could also be deployed in cartridge form.

Voxel8 seemed a little vague on their intentions. At first, their goal is to sell a pilot machine to others to generate interest in the technology. However, we’re not sure if, long-term, they intend on licensing the technology or making printers with it. Or both. Eventually they hope to develop a full manufacturing platform.

For now they’re selling a “Developer’s Kit” that includes not only the printer, software and support, but a reasonable quantity of consumables suitable for serious experimentation. Pre-orders began this month at a price of USD$8,999.

Via Voxel8