Made In Space, a company dedicated to the idea of taking 3D printing off the surface of the earth, finally sent their gear aloft.

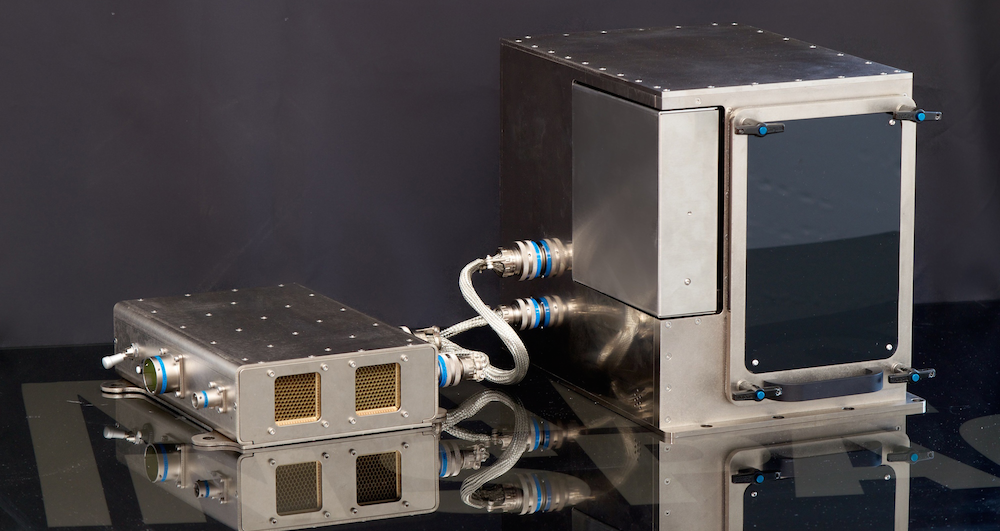

Onboard the cargo of CRS-4, a SpaceX resupply mission to the International Space Station, is the first actual 3D printer to head into orbit. The printer is more-or-less a conventional plastic extrusion 3D printer with specialized features enabling (hopefully) successful operation in microgravity.

Late last night the vehicle successfully launched from Cape Canaveral as shown at top. The Dragon cargo capsule shown here is now enroute to the International Space Station and is due to arrive sometime on Tuesday, when it will be docked and unloaded. Somewhere boxed inside this capsule is the Made In Space 3D printer.

Just so you know, the machine uses 1.75mm ABS filament, printing 0.25mm layers in a build volume of 50 x 100 x 50mm. It’s not a very large build volume to be sure, but the purpose of this mission is not to build large objects; it’s to see if you can 3D print at all.

While the Made in Space team has spent some 30,000 hours of testing, including 400 microgravity parabolic flights (which provide a moment or two of weightlessness), many questions remain.

Think about the problem they’re facing: without gravity, how would a 3D printer work? Plastic extrusion 3D printers do rely on gravity to perform many of their functions, from ensuring layers stick together to reliable feeding from the material spools.

Among the questions we imagine will be tested include:

- Can mere surface adhesion replace gravity as the means by which layers stick together?

- How can raw filament be delivered without gravity assist?

- Can the possibly toxic and certainly annoying ABS fumes generated during printing operations be successfully filtered?

- Will a print stick to the print surface during lengthy runs?

- Can a 3D printer operate in microgravity without spilling plastic bits that might float around the space station?

- How do you remove a print from the build surface in microgravity?

- Will 3D printed parts be sufficiently strong for practical use on the station?

Knowing as we do how unreliable personal 3D printing can be, we also wonder whether the astronauts will become frustrated after a few print failures.

Via Made in Space