An Australian company hopes to launch a new delta 3D printer this month.

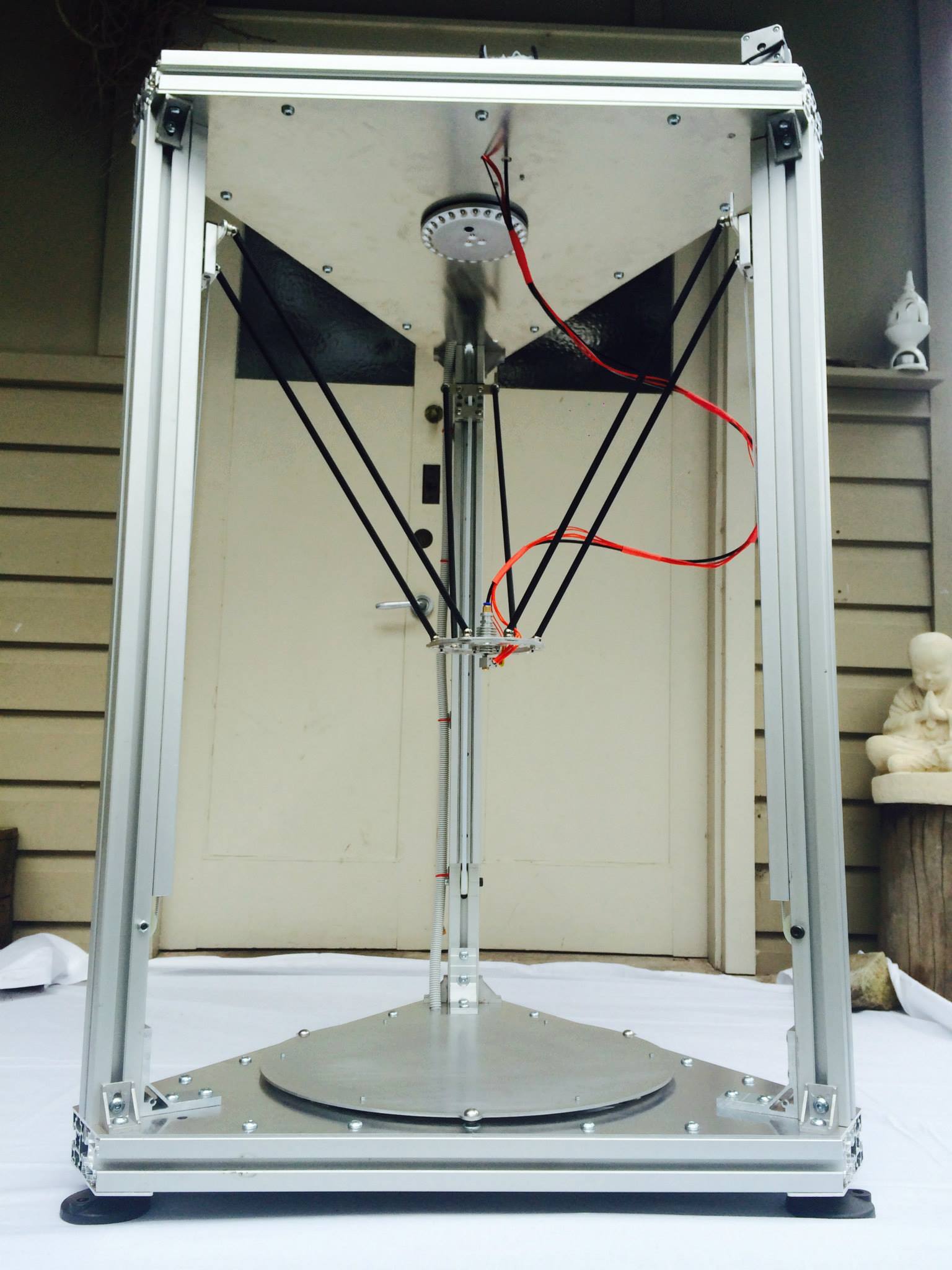

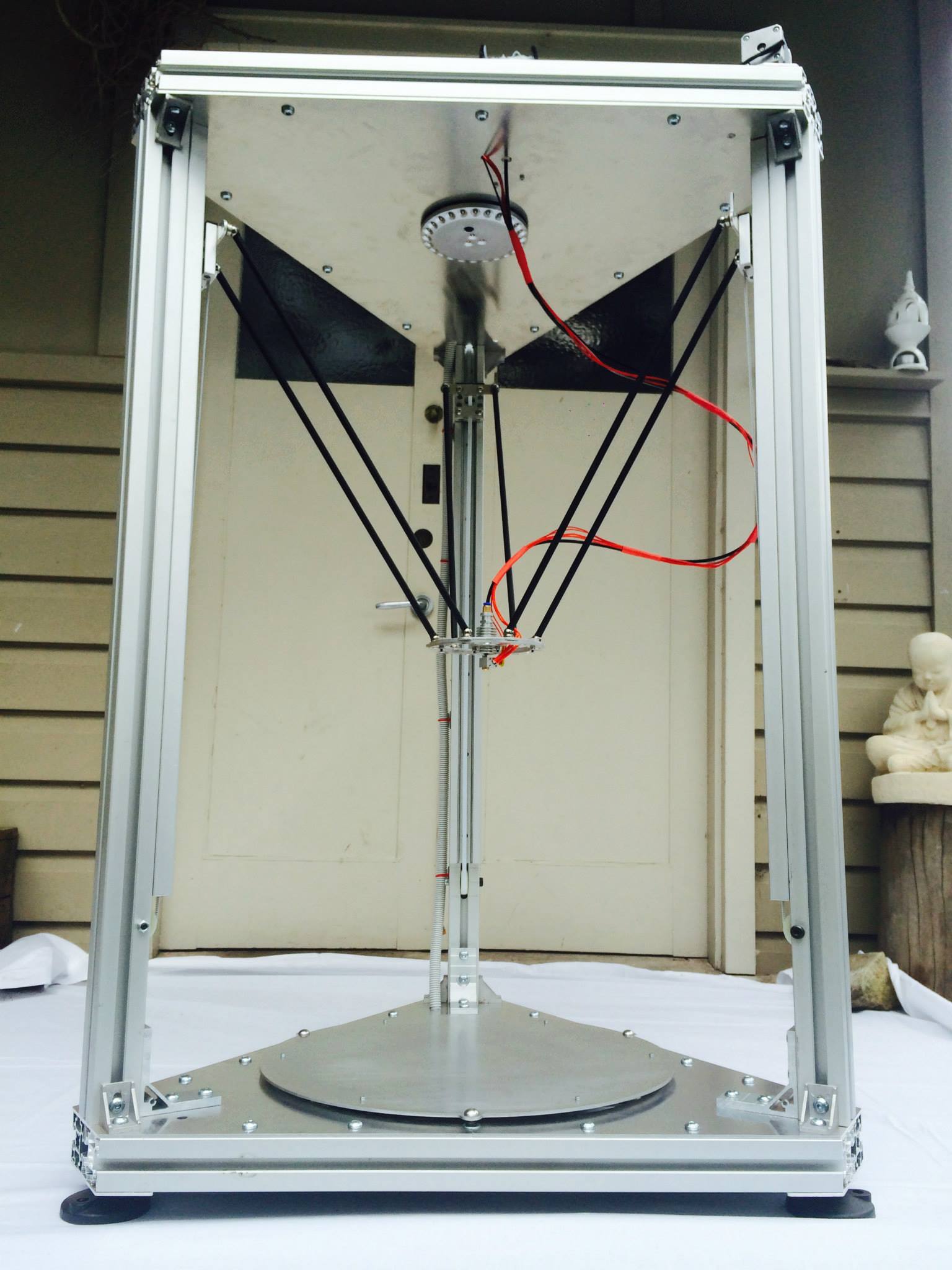

Delta 3D printers are the “other” way of making an extrusion-based 3D printer. While the traditional approach has been “cartesian”, meaning the extruder follows an “X Y Z” or “left-right, backwards-forwards, up-down” three-way orientation, a delta 3D printer uses a different approach entirely to move their extruder around. It’s based on three mechanisms that shift slightly to move the extruder around as you can see in the image above.

MetalTree Industries is working on the machine in that image. It’s a large 1.2m (2.5 feet) tall, enabling a cylindrical build volume of 350mm diameter and 480mm tall. That’s pretty big!

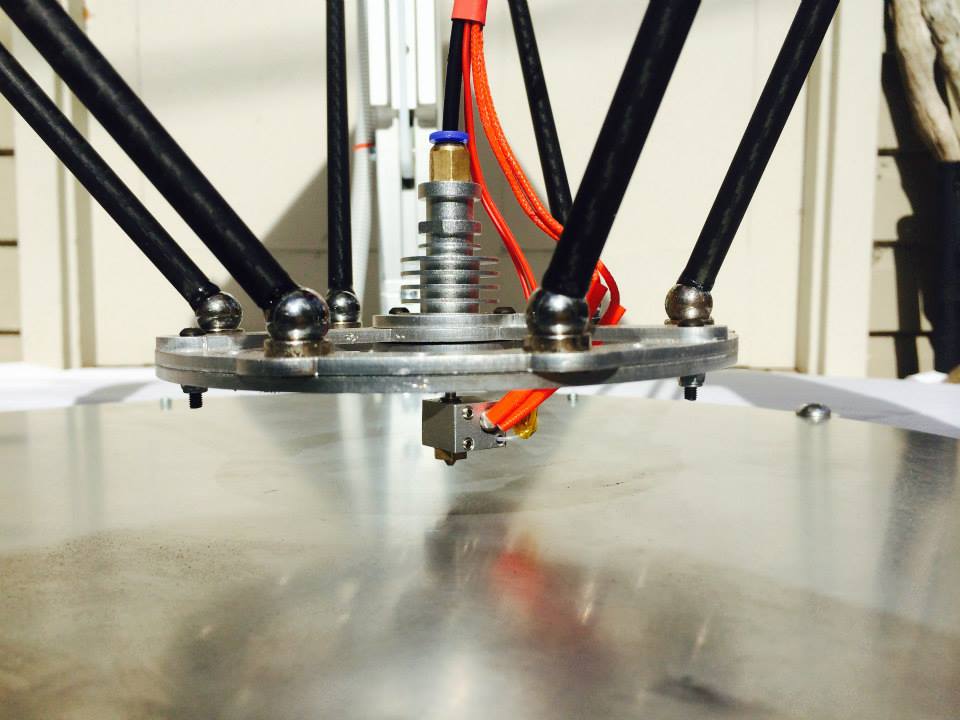

The machine appears to use metal parts in most components, making the machine robust and less likely to wobble. It’s also designed to accommodate a second extruder, although that doesn’t seem to be in the initial version. The carbon-fiber extruder arms are magnetically attached ball joints to eliminate backlash. The design even includes laser cut “alloy effector” to eliminate the need for a hot end cooling fan.

They’re hoping to show off the new machine at the Sydney Makerfaire this August 16th. No word on pricing as yet.