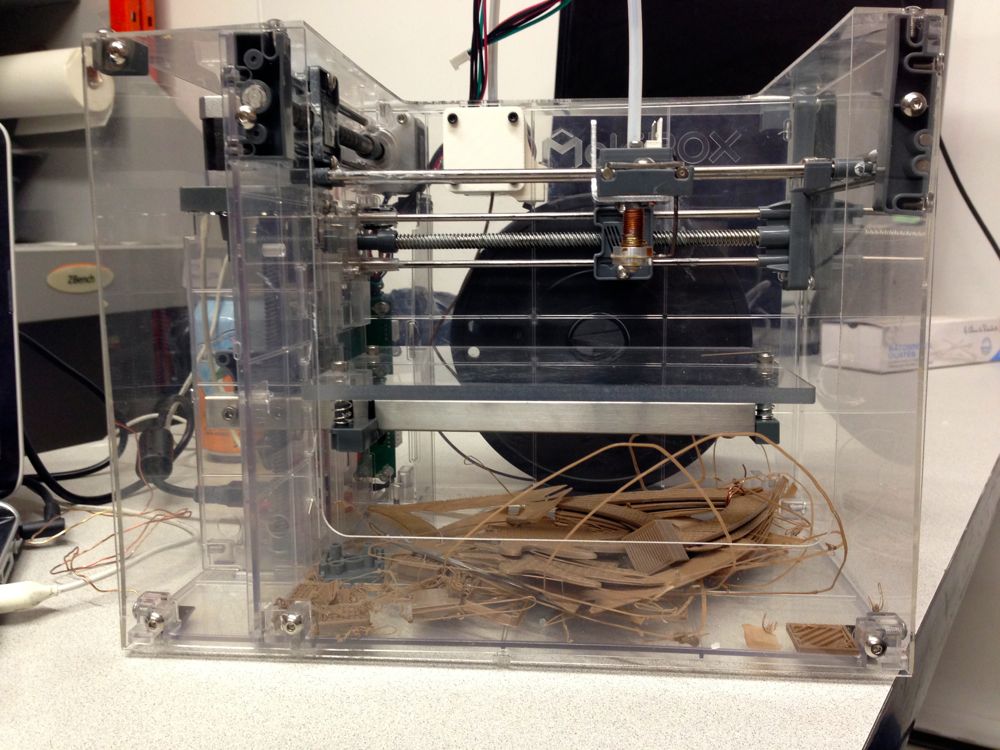

At the Fabbaloo Lab we managed to get our hands on a MakiBOX LT and checked out the USD$200 3D printer.

As you might expect, a USD$200 machine is neither fancy nor large. But it is functional. The acrylic construction is sufficient for basic 3D printing, although only in PLA as ABS is not really practical without a heated bed.

Extruder jams are relatively easy to fix – and the extruder itself is easily removable for direct access.

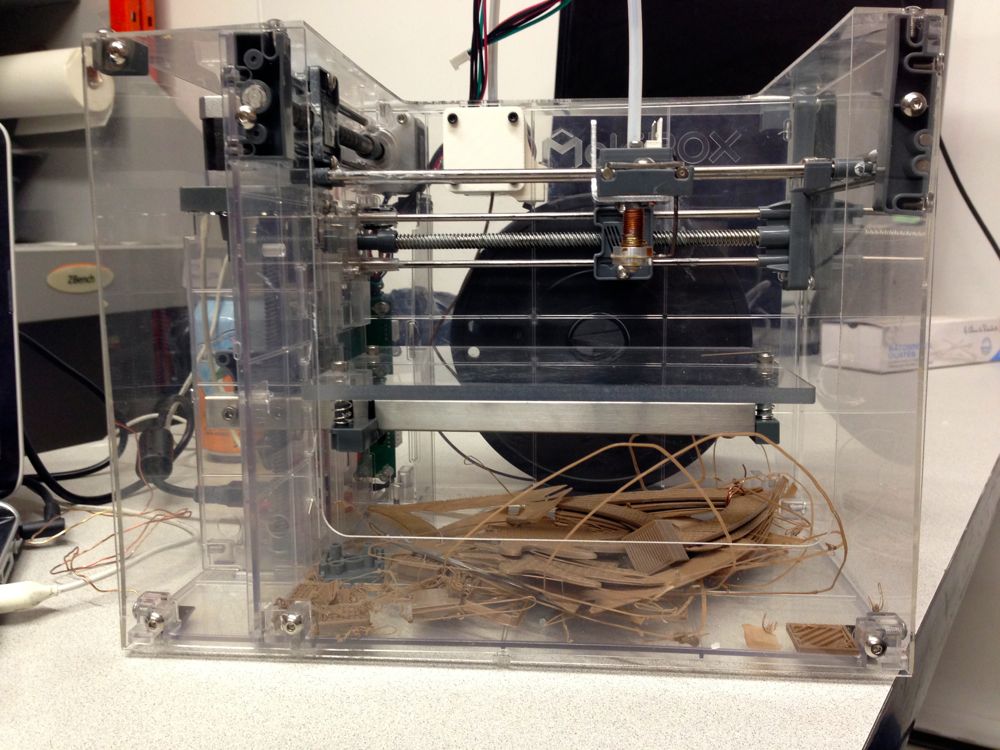

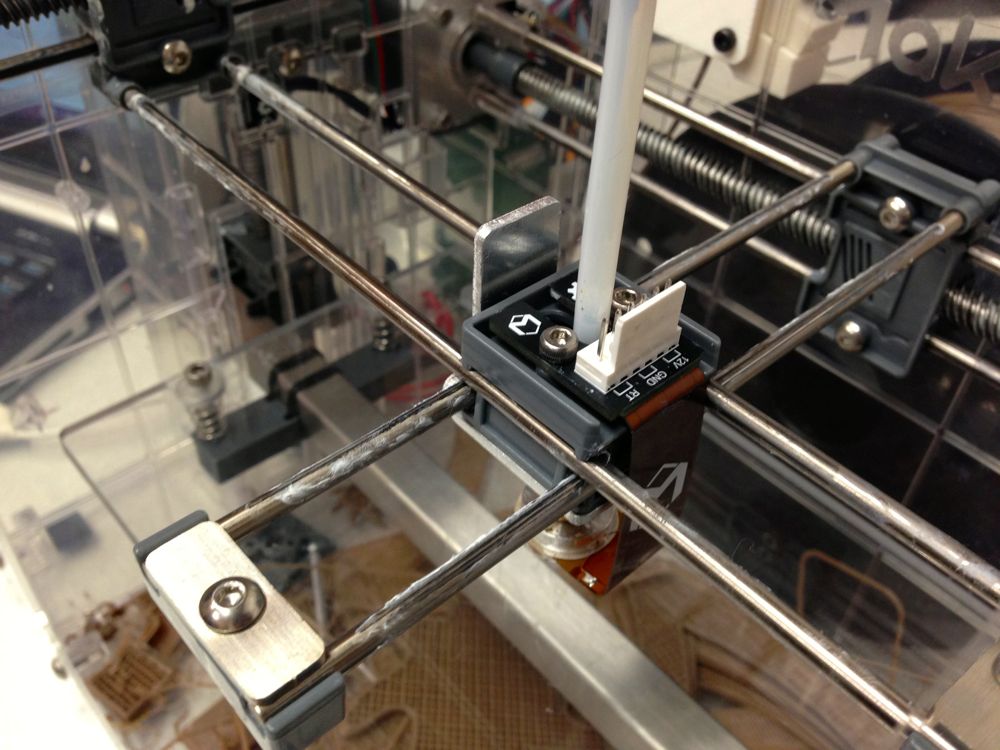

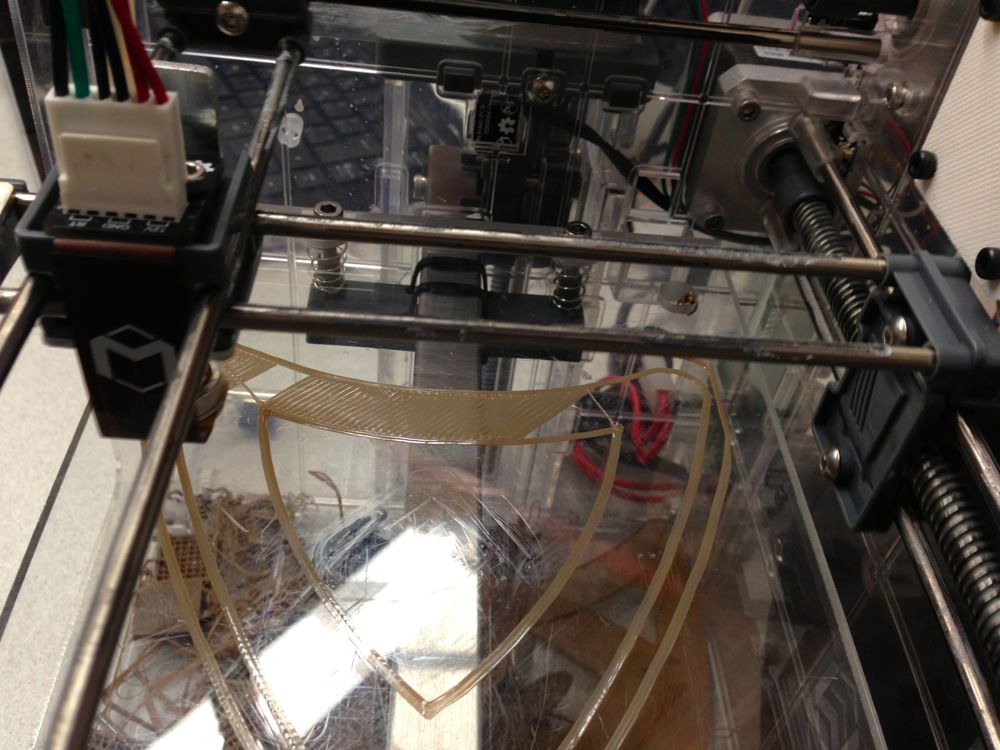

The mechanics of the MakiBOX are fascinating. We didn’t think they would work on first glance, but after observing print operations it seems they do. What we were concerned about is visible in this image, where you can see the X-axis bridges across the build volume. The interesting bit is the Y-axis which simply cantilevers forward from the rear. There is NOTHING holding up the close end of the Y-axis. It’s actually wobbly when touched. However, during printing it seems quite stable – although it’s likely susceptible to any nearby jiggles.

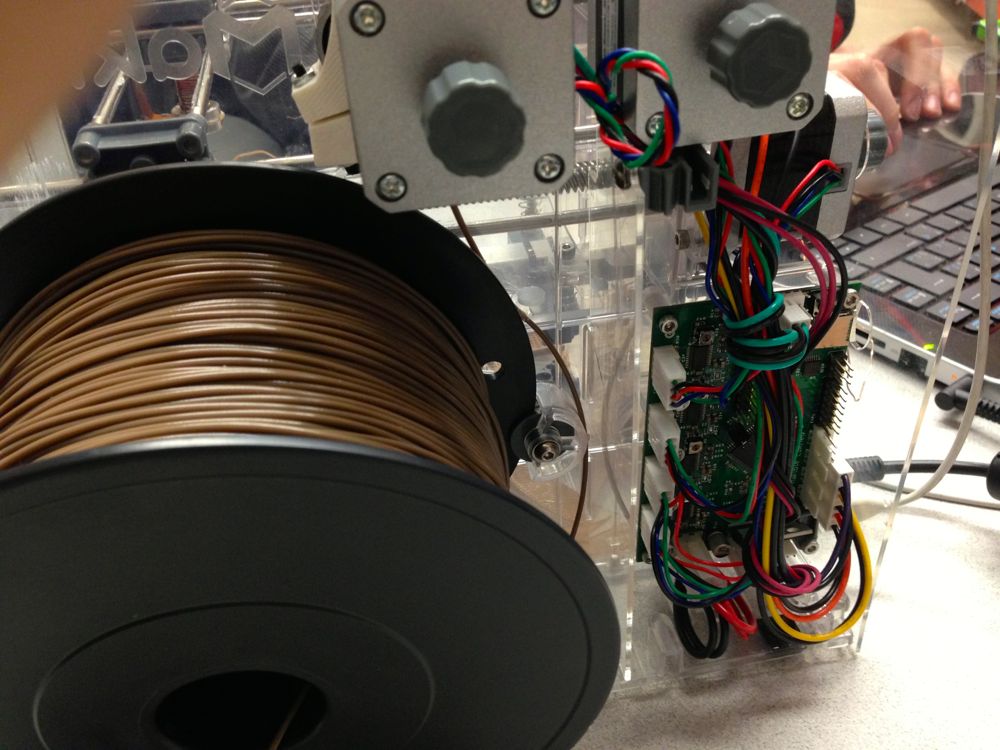

There is nothing fancy about the MakiBOX’s electronics. They are simply strapped to the backside of the machine beside the filament. Easy access, but not particularly attractive. If you want attractive, you’ll pay a lot more.

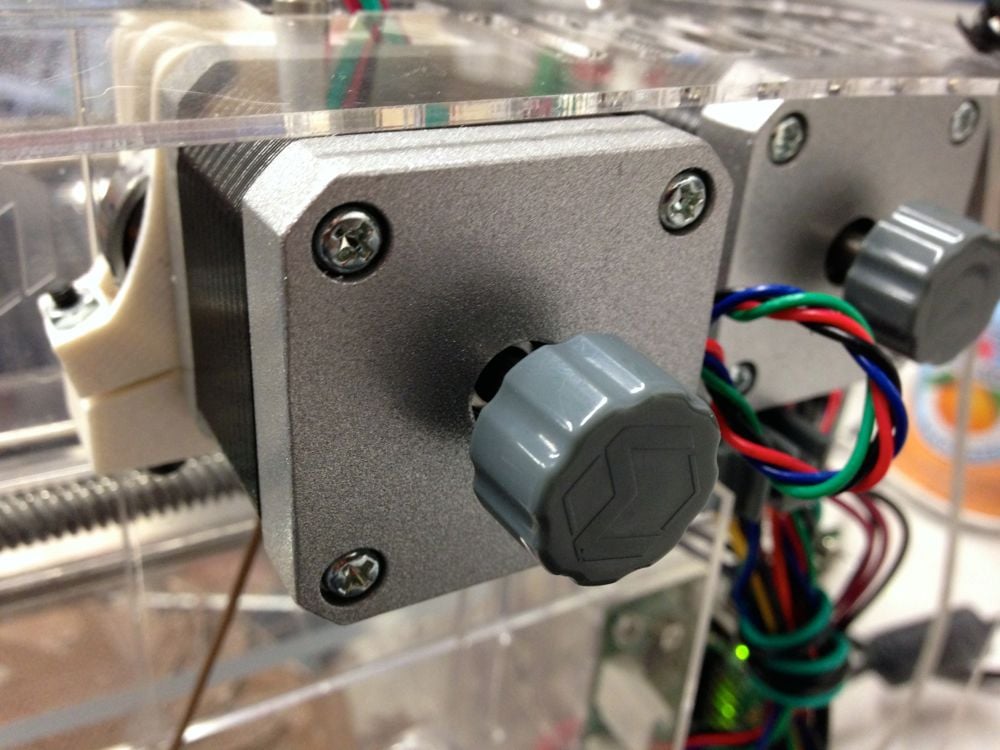

Loading and adjusting the machine is convenient due to the finger-knobs installed on several of the stepper motors. You simply turn them to feed filament forward or backward, for example.

How easy is the machine to operate? It’s about what you expect: a series of different software programs must be used, parameters must be set. It’s often a search for the correct combination of parameters to get a successful print, similar to other low-cost 3D printers.

This is a machine for those who like to tinker (and save money). It’s not a machine for consumers. So far, MakiBOX has sold over 1,000 units.

Via MakiBOX