Jim Smith has made a habit of building massive 3D printers, but now he’s used them to create an even larger project: a 3D printed kayak.

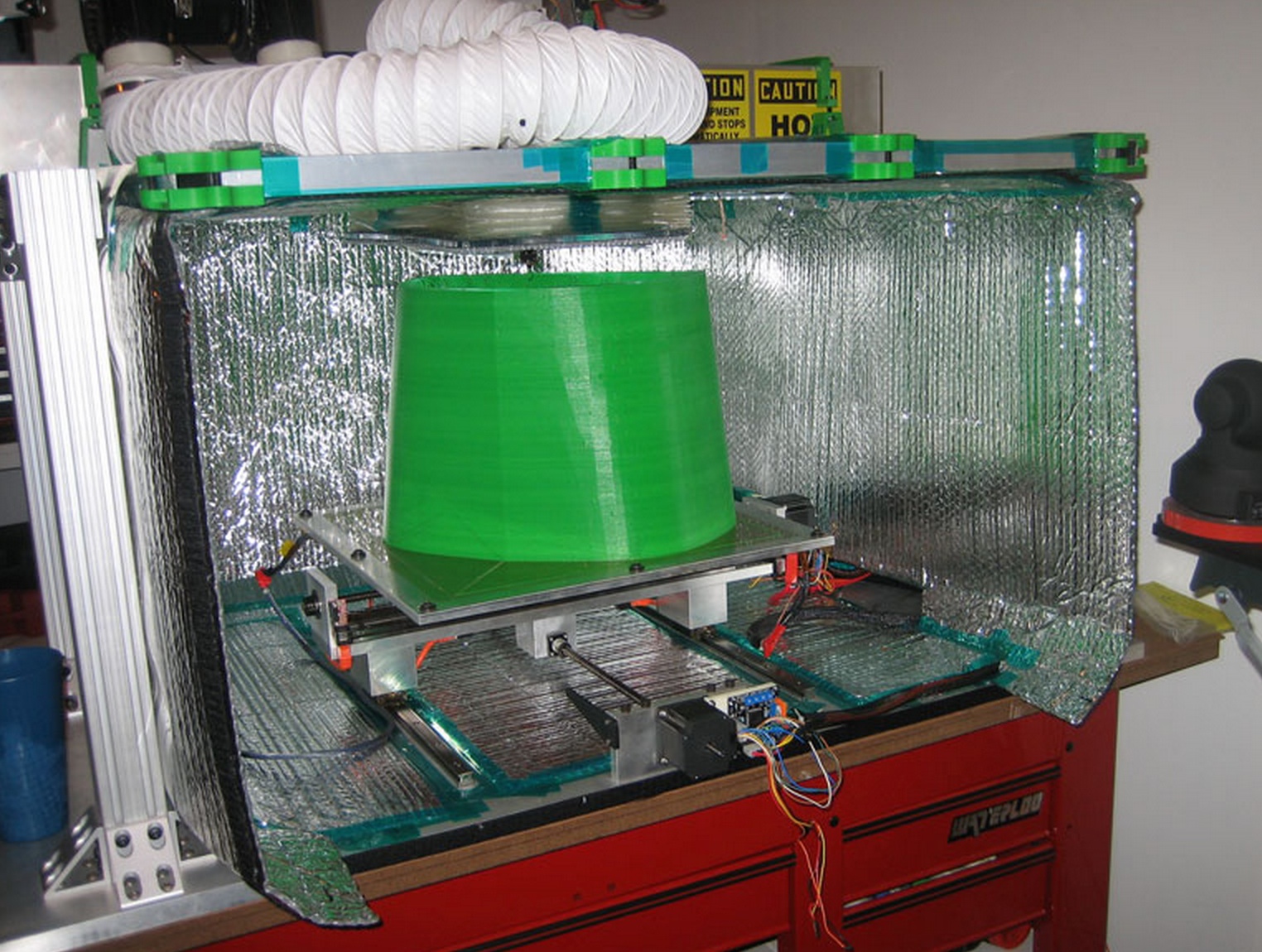

Several years ago Smith created a homebuilt extrusion-based 3D printer with a build volume of 403 x 403 x 322 mm. He’s been tuning and modifying it since, most recently adding a heated build chamber for producing warp-free large-sized ABS parts.

We’re not certain why Smith chose to 3D print a kayak, but it is indeed a dramatic demonstration of what is possible with personal 3D printing equipment.

From a standard kayak design, Smith adapted the 3D model to increase the feasibility of 3D printing:

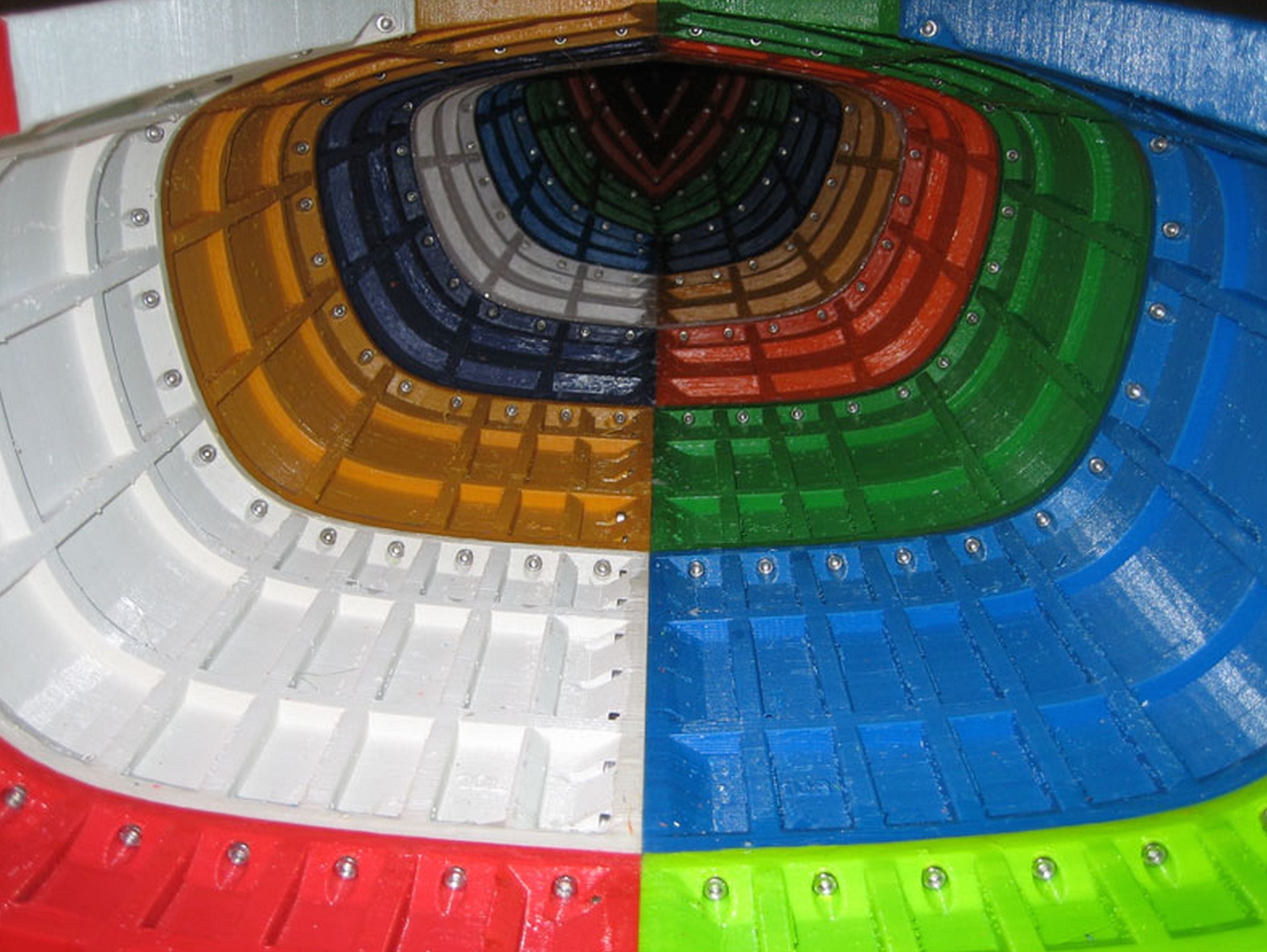

To reduce print time and material usage, the kayak is printed at a 0.65mm layer height. It features a 6mm thick hull with a built-in, internal rib/support structure to give it strength, yet be lightweight and use less ABS plastic.

But hold on – this boat is over 5m (16ft) long! This is an enormous object to produce on home equipment, perhaps the biggest hobby 3D printing challenge we’ve ever encountered. According to Smith, the project took over 1000 hours of 3D printing and almost 30kg (65lbs) of ABS material to produce the 28 interlocking parts.

It’s an incredible feat, but can it be done by others? Clearly this project occupied significant time and focus by Smith. If plans for ultra-large projects such as a kayak were published, would others repeat the work, given a demonstration that it is possible?

We suspect few people would have the ability to keep at a project like this, but some certainly would. Why? We think it’s simply the amount of time required. Were 3D printers significantly faster, it may be that home printing of large objects could become more common.

In the meantime, 3D printed kayaks and other huge items are the realm of pioneers like Jim Smith.