Need to print out a lot of items quickly? You might want to check out the Revo.

A problem consistently encountered by makers using 3D printing technology is the delay during printing. Printing a single object can take hours. That’s OK if you happen to be making one-off prototypes or custom items for single use, but what happens when you need a hundred items? Or a thousand?

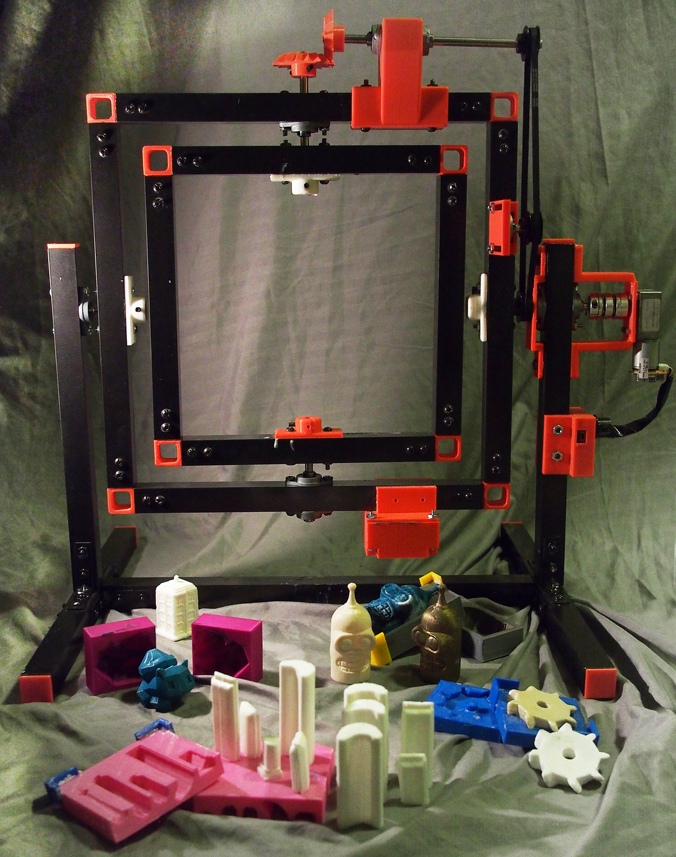

One solution is to complement your 3D printer setup with a rotational caster. This is a machine that can be used to quickly manufacture larger numbers of parts by using a traditional method: casting.

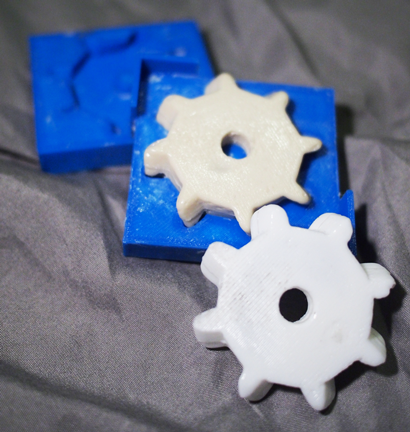

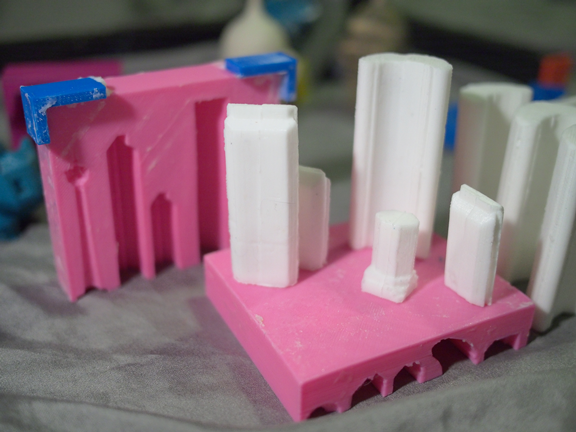

Here’s how it works: design and 3D print a mold of your desired object. Don’t be discouraged – a mold is often simply a negative of the desired object, frequently cut into a couple of parts to enable mold reuse. Then the mold is placed in a rotational caster along with a liquid material such as plastic, wax or even food material. The caster rotates the mold in every direction, ensuring the liquid material reaches all cavities in the mold. After waiting a few moments for the liquid to cure, release the finished object from the mold.

That’s the principle behind the Revo, an upcoming rotational caster. Their prototype was able to produce 100 snowglobe models in one fifteenth the time it would have required if using only 3D printing. Magic Maker, the company behind the Revo, says:

The revo is a desktop rotational casting machine, and it’s going to become your 3D printers new best friend. Make duplicates of your favorite 3D models every 10 minutes, and make those parts out of multiple materials, including plastics, wax, chocolate, amber resins, and more!

Unfortunately, the machine is not yet available. However, Magic Maker says they’re planning a crowdfunding campaign in “early 2015”. Watch for it!

Via Magic Maker