We’re checking out a new startup that seems to have invented a very different method of 3D printing colored objects.

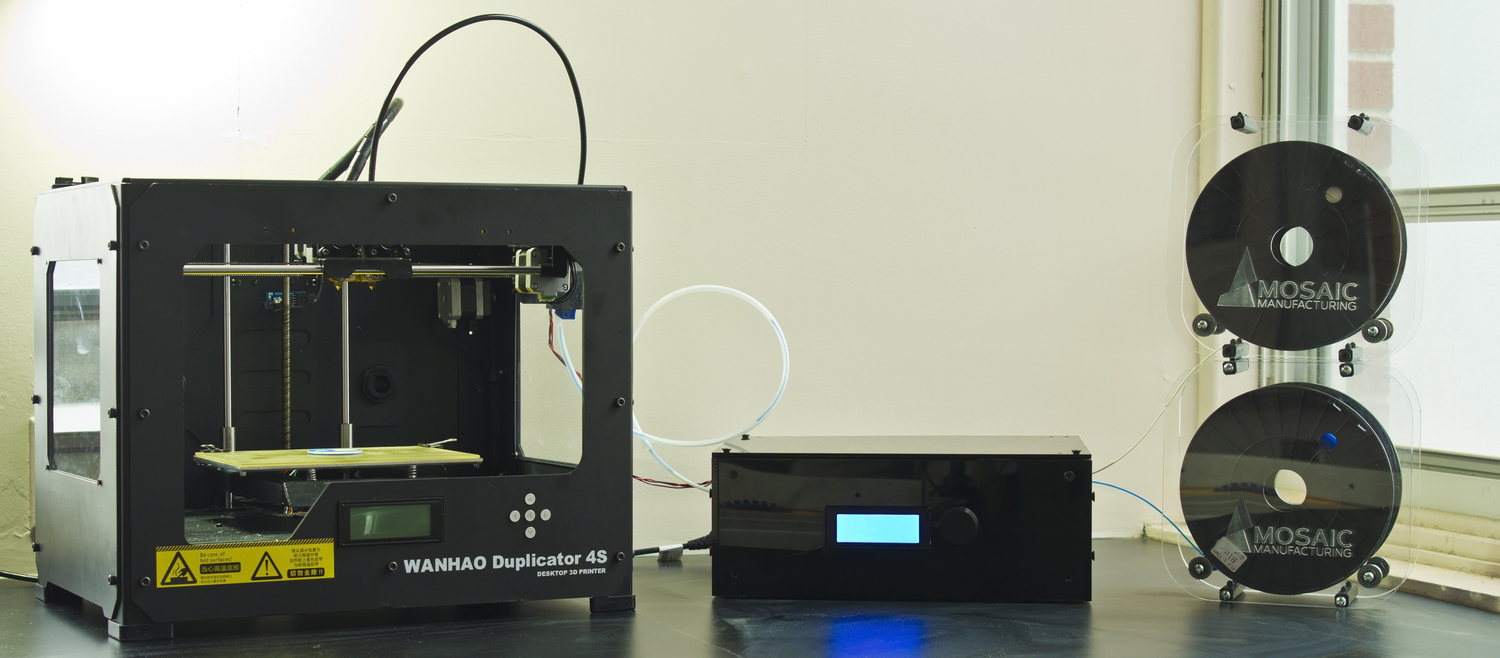

Mosaic Manufacturing uses your standard filament-based 3D printer in a way it hasn’t done before to achieve much higher quality color prints.

The problem with the standard multi-color approach is that two (or more) extruders and hot ends are used. These two extruders must be in very precisely known orientations relative to each other, or else the print becomes distorted at the color boundaries. As you can see in this image, the “dual extruder” solution often provides less than optimum results.

The Mosaic Manufacturing approach simply uses a single extruder. But how, you ask? They apparently put the colors into the filament and then print it. Here’s what they say:

Mosaic’s solution turns your single colour 3D printer into a multi-colour 3D printer. Our product takes multiple single colour filaments and creates a single filament that is comprised of multiple colours. This approach enables controllable multi-colour functionality from a single extruder.

Mosaic’s software interprets your multicolour model to determine exactly which colour needs to be placed at what order to get the exact output the user desires.

So it would appear they analyze the GCODE to determine precisely how much filament length is required for each color section and then push that filament through the extruder. As soon as a different color is required at the hot end, it has already arrived through precise filament length calculations.

This is an extremely flexible approach that should be adaptable to many printers – but amusing not those that use proprietary filament solutions. In fact, if this concept works in practice, one could imagine a more advanced version supplying far more than just two kinds of filament.

It could change any single-extruder 3D printer into a multicolor printer.

The filament shuffling is done by an external box as you can see above, but the company suggests they’re intending on providing an API for 3D printer slicing programs to directly integrate with the Mosaic box. This could ensure even more accurate color switches.

The product is not yet available, but you can bet they’ll have a whopper of a crowdfunding launch when they’re ready.

Of all the crazy schemes we’ve seen to print in color, this one seems to make the most sense. It could actually work – and work well if carefully tuned.