Yesterday we wrote on TNO’s work towards the challenge of 3D printed food. They’ve been experimenting with various processes and even combined their work with that of traditional chefs to create unique high-end dishes.

But from a 3D printing point of view, we see a series of rather difficult challenges that must be worked through by anyone venturing into the 3D printing of food.

- Safety: Unlike other types of 3D printing, each item of 3D printed food could potentially be eaten. Therefore food safety is a must. But to achieve food safety, a 3D food printer must certify safety along the entirety of the path food material takes through the device – and that is difficult.

- Timing: While you can leave a spool of ABS in your plastic 3D printer for weeks (and perhaps even years) without issue, this will not be the case for many food materials, which could expire within hours. Food materials must be treated very differently.

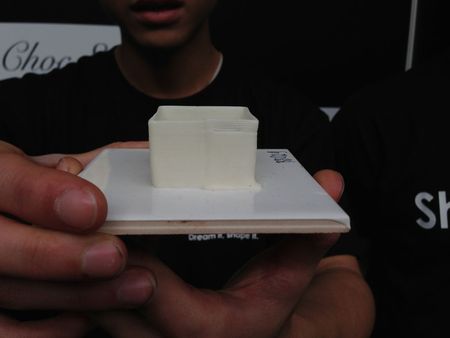

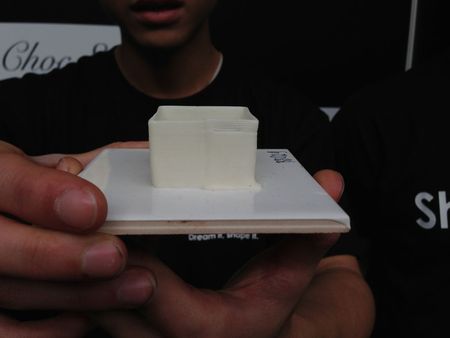

- Structure: Generally the engineering characteristics of food material are not considered during cooking, but when you’re 3D printing them, they are much more important. Food materials tend to be far less strong than even the weakest plastics, meaning 3D printed food can build objects will have some severe build geometry limitations. Consider the chocolate print above, which cannot be made taller without slumping.

- Designs: If there are severe geometry limitations, then the software used to create 3D models for food printing must account for them. We’re not aware that such software exists yet, and we suspect it could be quite complex due to the vast number of potential printable food materials.

- Taste: Unlike plastic 3D printing, you (or someone) may have to consume the output. It must taste good, if not at least barely palatable. How this is accomplished after material travels through a machine is a matter for food scientists.

- Multiple materials: Unless it’s pretty special, dishes made from a single ingredient tend to be pretty boring. Thus it seems that a successful food printer would likely have to be able to combine multiple foodstuffs into interesting combination dishes. Plastic 3D printers have had great challenges to develop multiple extruder capabilities, and we expect no less with food printers.

Widespread 3D food printing? Probably experimental for quite a while yet.

A while ago NASA funded 3D food printer. I think that with all these efforts, we could be eating 3D printed food within a decade! 🙂

A while ago NASA funded 3D food printer. I think that with all these efforts, we could be eating 3D printed food within a decade! 🙂