If you’re 3D printing with plastic filament, you’ll be familiar with the layered effect, where progressive extrusions accumulate into an object. The object has the correct shape, but has unsightly ridges. What to do?

You can eliminate ridges with the Acetone technique, but it’s relatively dangerous, as acetone is flammable and generally not very nice. Another way to smooth your ABS prints is to use Stratasys’s FinishingTouch Smoothing Station. We got our hands on one and took a test drive.

You can eliminate ridges with the Acetone technique, but it’s relatively dangerous, as acetone is flammable and generally not very nice. Another way to smooth your ABS prints is to use Stratasys’s FinishingTouch Smoothing Station. We got our hands on one and took a test drive. The FinishingTouch uses an approach very similar to using acetone, but it’s much more optimized – and safer. The device has two chambers. Your ABS object is first suspended in a refrigeration chamber that chills your object to a cold temperature.

A foot switch then opens up a second chamber, into which you dip the chilled model. This second chamber contains a heavier-than-air vapor from a rather expensive liquid chemical called Vertrel. The hot vapor instantly condenses equally on all nooks and crannies of the chilled model – and then slightly softens the ABS. Chilling is perhaps the longest portion of the process.

A dip of only 30 seconds is necessary to get preliminary results. Repeated chilling and dipping gradually improves the process. Here you can see fantastic results of a scanned figurine printed at 0.25mm resolution. It’s very smooth – and even glossy!

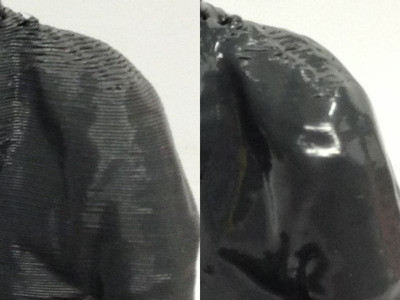

A closeup view of the figurine before and after shows the capability. This was obtained with only two dips. We expect prints of 0.1mm would come out almost perfectly smooth and glossy.

There are limits. This figurine was printed at a huge 0.5mm resolution and despite repeated dips into the Vertrel vapor, it just would not smooth out properly. Rule of thumb: 0.25mm or less to get good results.

There are limits. This figurine was printed at a huge 0.5mm resolution and despite repeated dips into the Vertrel vapor, it just would not smooth out properly. Rule of thumb: 0.25mm or less to get good results. While the FinishingTouch produces amazing results, there is one slight problem. It’s expensive. Very expensive. Over USD$30K expensive.

If you happen to have access to one, you’re very lucky. If not, you’re probably going back to acetone.

Idea: Could the acetone dipping process be improved by pre-chilling the object? We think so.