Can you 3D print a working car? The folks making the Urbee car believe so. They’ve prototyping an ultra-efficient (300 miles per gallon, 0.8L/100Km) urban vehicle whose body is entirely 3D printed.

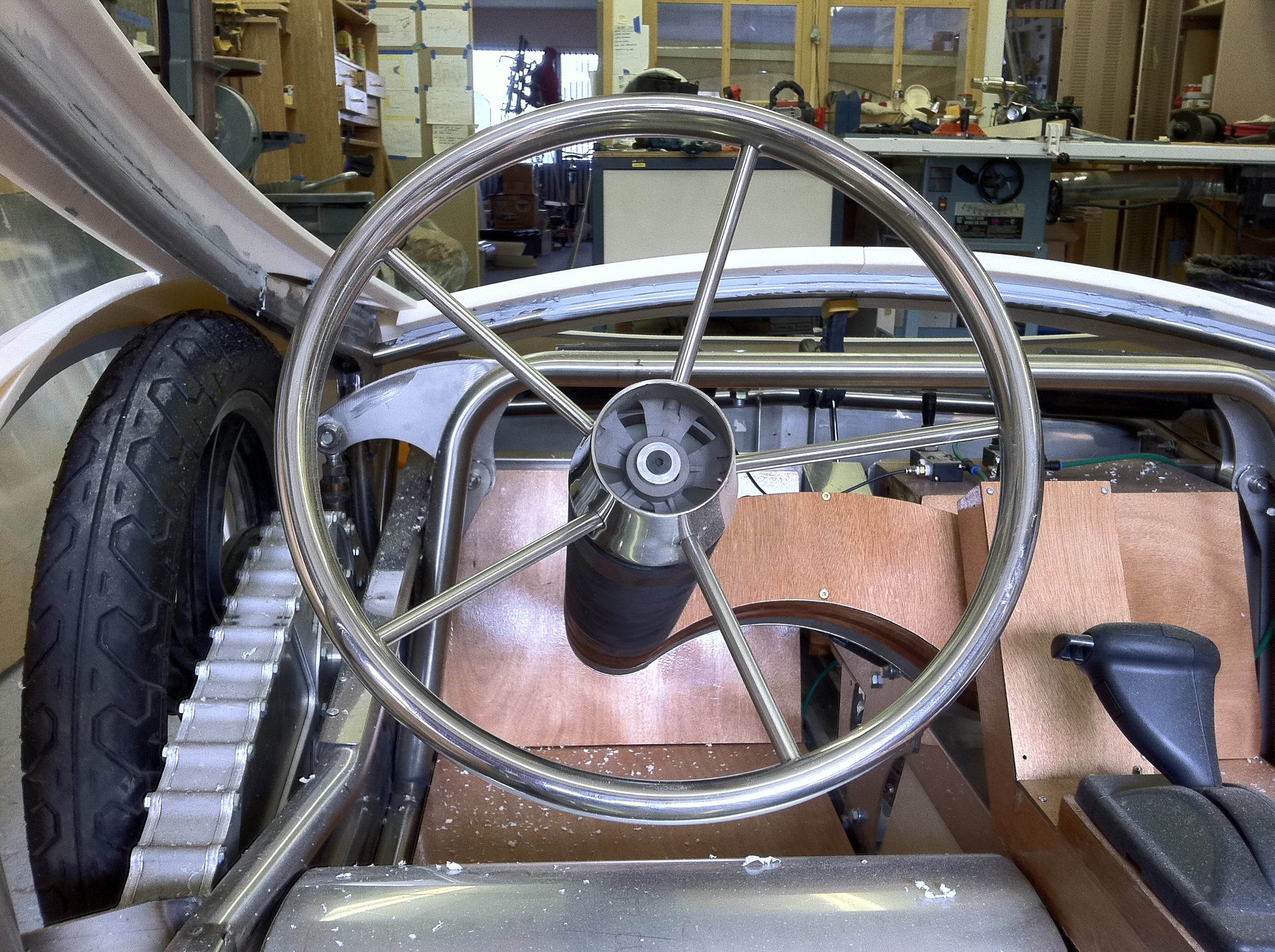

Can you 3D print a working car? The folks making the Urbee car believe so. They’ve prototyping an ultra-efficient (300 miles per gallon, 0.8L/100Km) urban vehicle whose body is entirely 3D printed. We recently visited the Urbee shop and found it to be a very unusual vehicle:

- Two seater with some room for cargo

- Extremely low air drag coefficient

- Three wheels; two fixed in the front and one for steering in the rear

- Dual electric motors, one on each front wheel (apparently one engine can be swapped in as little as five minutes; try that on a gasoline powered vehicle!)

- 1200 pound (550Kg) vehicle

- Designed for moderate urban use

We were a little skeptical of the three wheeled concept, after having watched Top Gear’s experiments with the three-wheeled Reliant Robin. However, the Urbee’s single wheel is in the rear, not the front, leading to a lot more stability. The Urbee is a very low-to-the-ground car, and that helps, too. Lead designer David Bernhardt told us:

We were a little skeptical of the three wheeled concept, after having watched Top Gear’s experiments with the three-wheeled Reliant Robin. However, the Urbee’s single wheel is in the rear, not the front, leading to a lot more stability. The Urbee is a very low-to-the-ground car, and that helps, too. Lead designer David Bernhardt told us: It drives just like a normal car… except in parking lots.

Through a partnership with Stratasys, the Urbee team has designed and 3D printed 20 parts that make up the exterior body of the car. While these parts are accurately printed, the Urbee team has found some challenges using them. Apparently the parts could be said to be “too accurate”, as they must be fitted onto a conventional frame that isn’t as accurate. Thus the frame’s inaccuracies are exposed, whereas they might not have been using traditional approaches.

Through a partnership with Stratasys, the Urbee team has designed and 3D printed 20 parts that make up the exterior body of the car. While these parts are accurately printed, the Urbee team has found some challenges using them. Apparently the parts could be said to be “too accurate”, as they must be fitted onto a conventional frame that isn’t as accurate. Thus the frame’s inaccuracies are exposed, whereas they might not have been using traditional approaches.  Nevertheless, the 3D printed body parts are as large as regular car panels and fit precisely into each other (click image for more detailed view.) The new process is also less labor intensive, symmetrically accurate and more environmentally friendly than typical custom fiberglass panels.

Nevertheless, the 3D printed body parts are as large as regular car panels and fit precisely into each other (click image for more detailed view.) The new process is also less labor intensive, symmetrically accurate and more environmentally friendly than typical custom fiberglass panels. More information at Urbee

Very interesting concept. In theory, now anyone who can afford the machinery involved can basically create their own cars.

electric motor rewinds