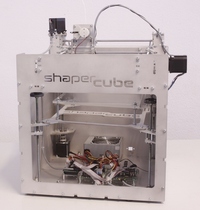

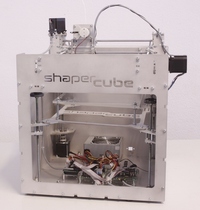

This German made €979 (USD$1,290) build-it yourself kit is based on the RepRap Darwin design and includes a rather hefty build volume of 190x200x185mm (slightly reduced if an optional second print head is installed).

The key specs:

- 3mm filament required

- 0.5mm nozzle

- Pre-assembled heater

- Acrylic print surface (heated option available)

- Rubber mounts to reduce vibration

- Up to 115mm/s XY print movement

- Online wiki with all the information required

One interesting feature that stuck out to us was the case. It’s made of water jet-cut aluminum. This ensures not only a groovy appearance, but makes the device very solid. However, water jet cutting sometimes leaves scratches and other messes on the aluminum surfaces, so Shapercube offers an option: glass-bead blasted aluminum panels for an extra €100 (USD$132). We’d take that option in a nanosecond.

Currently they’ve sold out the first batch and are awaiting a second production run.

The printer can print a limited set of plastics, including ABS and PLA most commonly. The surface on which the object is printed is acrylic – that's because the plastics being printed are most compatible with acrylic. In other words, they "stick" to the acrylic sufficiently to allow solid printing – but can be peeled off the platform when the print completes.

The printer can print a limited set of plastics, including ABS and PLA most commonly. The surface on which the object is printed is acrylic – that's because the plastics being printed are most compatible with acrylic. In other words, they "stick" to the acrylic sufficiently to allow solid printing – but can be peeled off the platform when the print completes.

So does this print on acrylic in 3D or is it an acrylic printer? I'm confused!

So does this print on acrylic in 3D or is it an acrylic printer? I'm confused!

A water jet cutter, also known as a waterjet is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found in nature but greatly accelerated and concentrated.

A water jet cutter, also known as a waterjet is a tool capable of slicing into metal or other materials using a jet of water at high velocity and pressure, or a mixture of water and an abrasive substance. The process is essentially the same as water erosion found in nature but greatly accelerated and concentrated.

its an awesome product to have… Thanks for info

While searching for some information on 3D print, I came across an interesting article titled “3D View of Patent Enforcement”. It is very informative and well written article. To read more please check: http://www.sinapseblog.com/2010/12/eto-know-more-about-intellectual.html

its an awesome product to have… Thanks for info

While searching for some information on 3D print, I came across an interesting article titled “3D View of Patent Enforcement”. It is very informative and well written article. To read more please check: http://www.sinapseblog.com/2010/12/eto-know-more-about-intellectual.html