Metal 3D printing startup Additive Industries seems to be succeeding, judging by their need for immediate hiring.

Last week our team crashed one of their regular hiring events, where they attract dozens of candidates interested in finding out more about this fascinating company.

If you’re not familiar with Additive Industries, it’s a two-year old 3D printing startup company based in Eindhoven, Netherlands, where they’re surrounded by manufacturing industries of all kinds.

Yes, they produce metal 3D printing equipment, but that’s where the similarity with other 3D printer manufacturers ends. The company spent considerable time examining the manufacturing workflows of nearby companies to deeply understand how 3D printing could optimally exist in a manufacturing process.

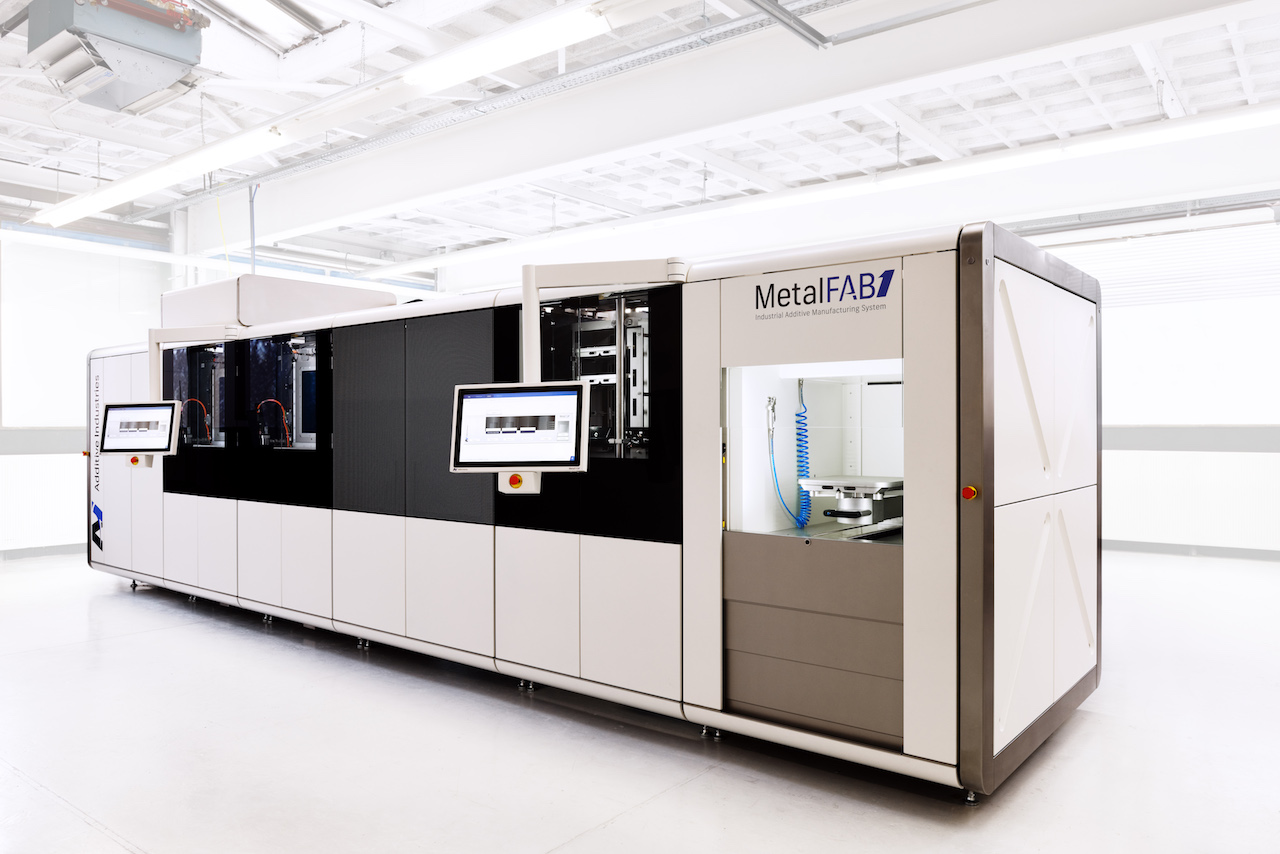

The result is their MetalFAB1, a powerful integration of several manufacturing processes. Here’s how they describe it:

MetalFAB1 is the first integrated metal additive manufacturing machine. Besides the 3D print process also stress relief heat treatment, automated build plate handling and storage are integrated in one industrial grade production system.

Think about this: if you’re a manufacturer and you purchase a 3D metal printer, you would have to determine methods of integrating it into your workflow. That takes effort, and once established, you still have to perform the work to shift your items from 3D printer to workstation to workstation in a manner far less integrated than that provided by MetalFAB1.

I find it very appropriate that Additive Industries has directly addressed the functional needs of manufacturers in this way, going far beyond just building a working 3D printer. This, I believe, is the best way to succeed in the world of 3D printing: make life easier for your clients first.

Their formula must be working, as they’ve shipped several of these large systems to more than one vertical industry. Although the system is still officially in “Beta” and being tested by these initial users, I understand things are proceeding very well. It sounds like they will be shifting to production models towards the end of this year.

Testing such machines is an interesting process, as apparently their initial clients are sharing experiences with each other to increase the learn rate and provide additional feedback to Additive Industries. I guess it helps to be near many manufacturers!

But what about their hiring? It’s very substantial. So much so that they’ve been holding recruiting events, where individuals either newly graduated or just interested in the company can drop by and chat with staff to find out more.

They currently post eight roles in a variety of engineering, administrative and design fields. But I’m told they eventually need to hire as many as 35 individuals. Are you one of them?