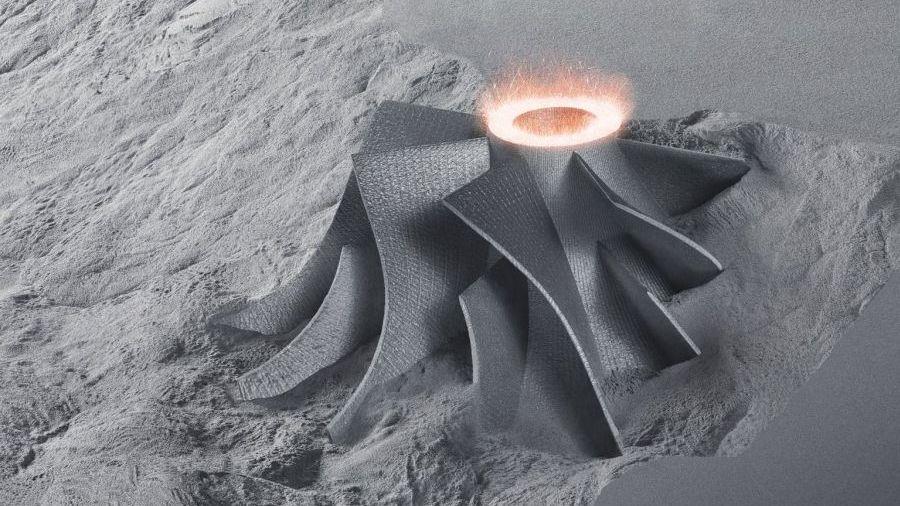

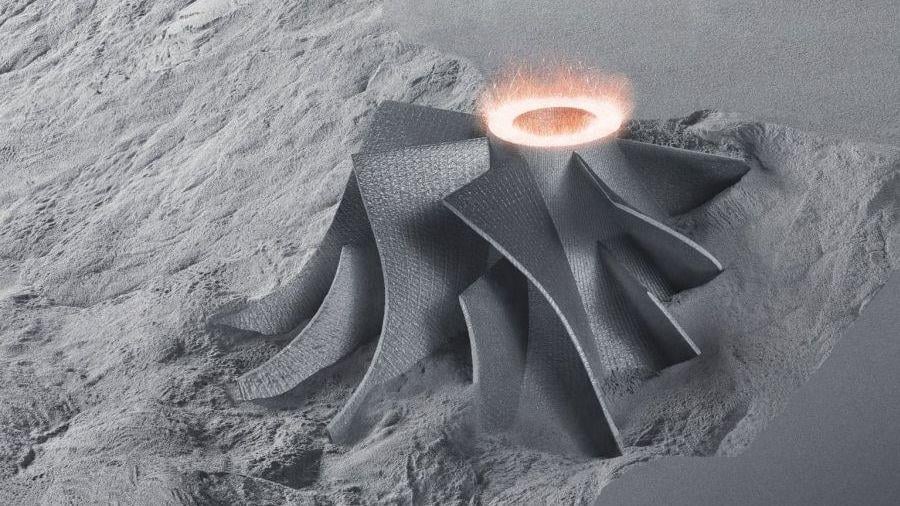

Burgeoning interest in metal 3D printing has caused some changes in the metal powder industry.

Recently specific industries have realized the value of metal 3D printing. Aerospace and automotive industries have been creating innovative parts that offer vastly lower weight or previously impossible designs. It’s becoming – or soon will become – a requirement to compete in particular industries. Imagine an aircraft manufacturer that can, say, reduce the weight of their product by five percent. That’s a huge advantage over their competitors, one that will have to be met by everyone, ultimately.

It seems that metal producers have noticed this pattern and have been gearing up for more sales.

Recently Arcam’s subsidiary AP&C in Montreal obtained funding to dramatically increase their metal powder production facilities. Obviously, it helps that Arcam just happens to be a manufacturer of metal 3D printers.

But others have done the same. China’s Advanced Materiel, for example, produces a wide array of metal powders made from a variety of alloys including titanium, aluminum, inconel, hastelloy, steel and more.

One aspect I’m wondering about is the regionality of such operations, however. In the case of plastic filament, a staple for desktop 3D printing, it has evolved into a regional business as the price of shipping the plastic destroys the ability to sell far from the source of production. Other local suppliers can produce the material and avoid the shipping surcharge from foreign suppliers.

But will this be the case for metal powder? There are two factors that may affect this analysis. First, the cost of metal powder is far greater than mere 3D printing plastic filament, so it’s possible the shipping cost would be such a small percentage of the total cost it may be ignored by buyers.

On the other hand, metal is a very heavy substance and thus shipping charges may vastly exceed the cost of shipping plastic per kg.

Ultimately I suspect the metal powder business will also become a regional, simply because it is a commodity-like business. One company’s pure titanium is the same as the next’s, so long as they meet quality and performance standards.

For now, however, as industry shifts towards larger-scale metal 3D printing, we will see a small explosion of metal producers focusing on 3D printing applications.