An interview with David Patrick of Shark Wheel dramatically shows in how 3D printing has utterly changed manufacturing.

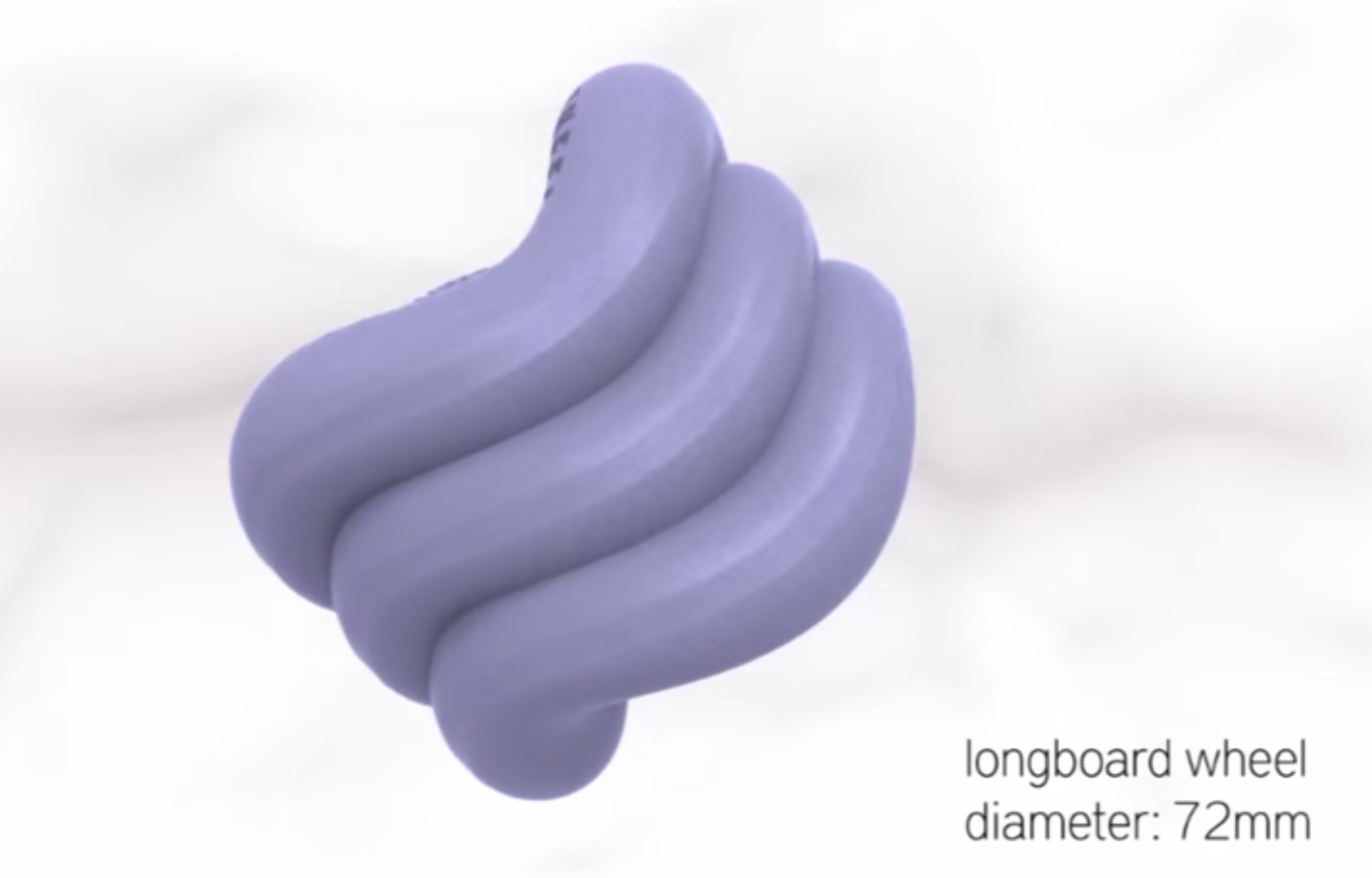

Shark Wheel designs a very unique longboard wheel whose geometry “is a perfect cube and a perfect circle and a perfect sine wave.” It looks very strange but apparently provides a natural rolling ability not found in common wheels.

The interview with the owner and inventor of the Shark Wheel, David Patrick, explains how 3D printing and subsequent urethane casting with BJB enterprises revolutionized his approach to making. His enthusiasm spills out of the screen, explaining how his normal approach, requiring months of effort and tens of thousands of dollars to produce a new design, was transformed into a three DAY process costing only USD$50. He says:

There’s literally no limitations. Complexity costs nothing; it doesn’t matter how complex the thing looks, that has nothing to do with how much it cost to print it. Back in this world [traditional manufacturing] the more complex something was, that was the death knell to kill whether not you probably could even go to market. Now I can take almost anything I can dream of and within the low thousand dollars be in full-scale production. That’s incredible!

Patrick says his company would likely not even exist were it not for 3D printing and related technologies.

It is incredible. And it’s the world we live in.

Via YouTube and Shark Wheel