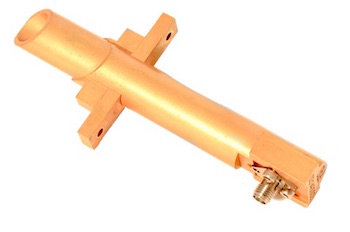

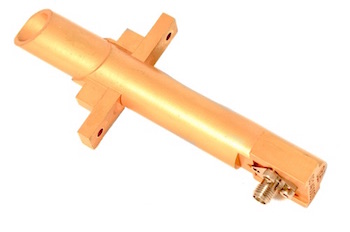

A company uses a combination of 3D printing and electroplating to produce lightweight microwave and millimeter-wave transmission components.

The process used by SWISSto12 involves first designing in CAD an antenna or waveguide, then 3D printing it in conventional plastics. This step enables the company to develop unique shapes whose geometry may not be possible with other techniques.

The final stage is to coat the component with copper, then subsequently a layer of gold to inhibit oxidization. The result is a unique component that’s of lower weight and still just as functional as any normally manufactured component. They explain:

The use of 3D printing open up possibilities for RF structures that were previously impossible to manufacture with conventional techniques. The use of plastics allows for weight reduction and thermal insulation. High quality copper plating ensures state of the art RF performances.

An example of where these could be used is aerospace or space applications, where weight is of considerable importance.

This approach also has another benefit: the company can rapidly produce customized components for clients requiring unusual designs. These would be more expensive than the mass produced variety, but for lower quantities, it would work for many companies.

Here we see a great example of how to leverage 3D printing for an unusual – and new – style of doing business.

Via SWISSto12