Two questions came to mind when I saw reports of a home-3D printed brace to support a broken wrist.

The project was done by Reddit contributor 3driven, a home operator of a desktop 3D printer. In the post, 3driven says after two weeks of a conventional brace, it became uncomfortable and it was decided to replace it with a 3D printed version. The project development approach was described:

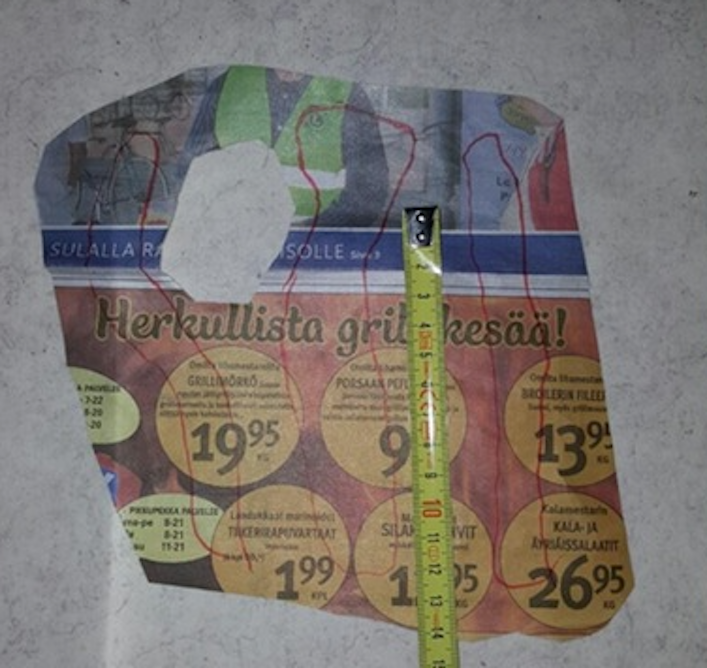

I took a piece of newspaper and twisted it around on my hand. Put the measuring tape on the picture and scaled the picture in Autodesk Inventor.

However, the molding part with PLA was time consuming process. It wasn’t enough to soak the PLA in ~80°C water, but I also had to use heat gun. Eventually I used (somewhat) heat protective clothing to help the molding process while the brace was on my hand. Softened the edges to make it more comfortable.

Evidently this was considered a success:

My orthopedist approved my design saying that if it feels good then it’s good. The fracture was stable and thus a fixed cast wasn’t needed. He also said that it was hard to prevent the healing process. So it was safe. This also allowed me to swim, wash the brace daily and enjoy the hot summer more without sweating too much.

That brings us to one of my questions: if we can do this, which apparently has been successful, should we? Should anyone in this situation attempt the same kind of project? One commenter tends to agree:

As a nurse this is my concern with people 3d printing their own medical devices. I have see home made medical devices go horribly wrong.

That’s my feeling on this as well; if one person can do it, it doesn’t mean others can also do it sufficiently well. Worse, if you can do it in one straightforward medical situation, it doesn’t mean it should also be done in less obvious alternate scenarios. If everyone was attempting this, surely there would be mistakes, some of which might be medically dangerous.

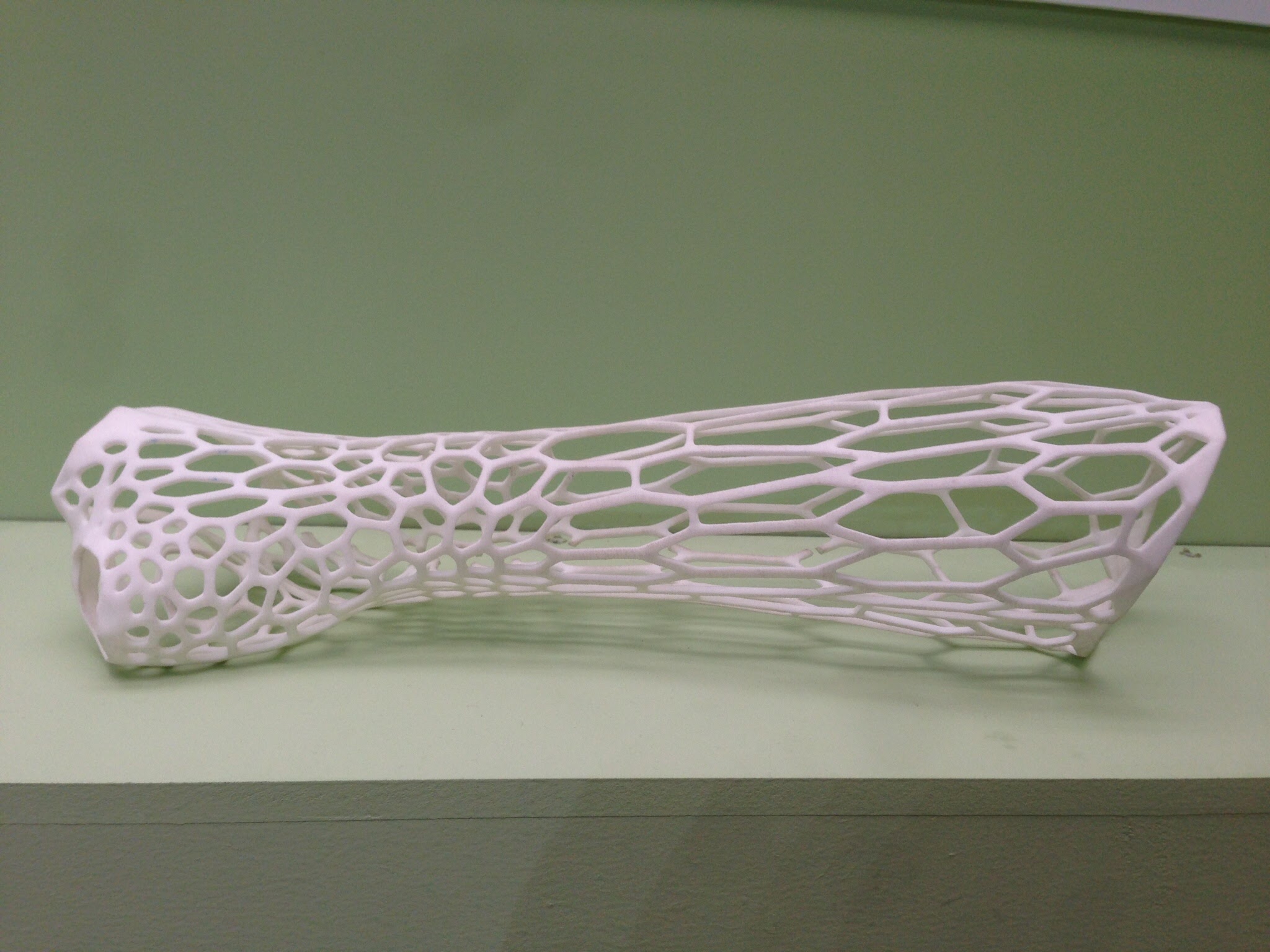

But the idea of a 3D printed cast or brace is still a good one. I first saw an attempt at a 3D printed cast more than three years ago, but for some reason it hasn’t caught on. While 3driven used a very simple pattern for the brace, it’s entirely possible to make them far more sophisticated by using alternate materials with structural patterns designed to provide maximum stress benefit.

And that leads to the second question: Why hasn’t someone developed a 3D model generator for this? I imagine the parameters, once identified, could be modified to fit by performing several simple measurements on the affected limb.

As 3driven states, 3D printed braces and casts permit swimming and other activities sometimes avoided by patients. They can also be re-printed in varying sizes, for instance if the limb’s swelling decreases.

3D printed braces and casts should be an industry of their own.

Via Reddit