While 3D printing technologies continue to be adopted by manufacturing, there are still some challenges.

One of them is part quality. Even while 3D printers can produce “impossible” geometries, the strength and dimensionality of printed objects may not always match that of conventional manufacturing approaches.

In other words, there’s a quality problem.

Manufacturers may shy away from 3D printing because they are unsure of the quality of 3D printed objects.

However, there are ways to overcome this challenge. One of them is to install a comprehensive quality control system such as PrintRite3D from Sigma Labs.

This system includes a number of modules that can provide comprehensive quality measurement for 3D printed parts.

Their “SENSORPAK” is a series of sensors that collect real-time data on 3D prints and can do so while the print is underway!

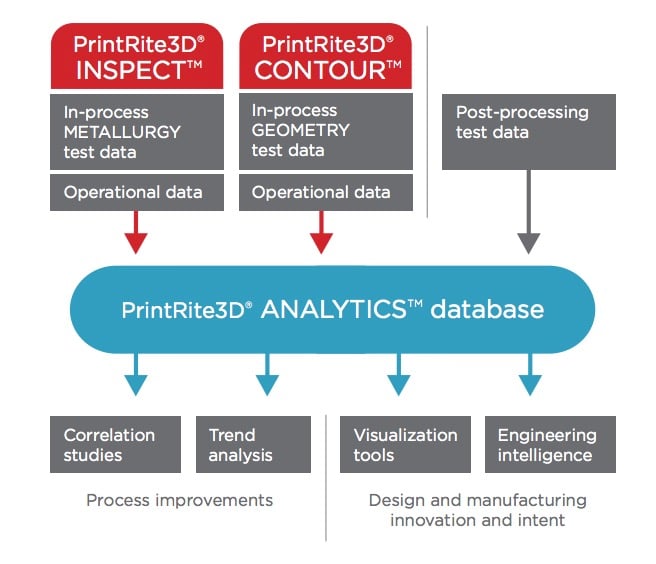

There are several modules in the PrintRite3D family:

- SENSORPAK, providing physical sensors

- INSPECT, which develops metrics for metallurgical properties

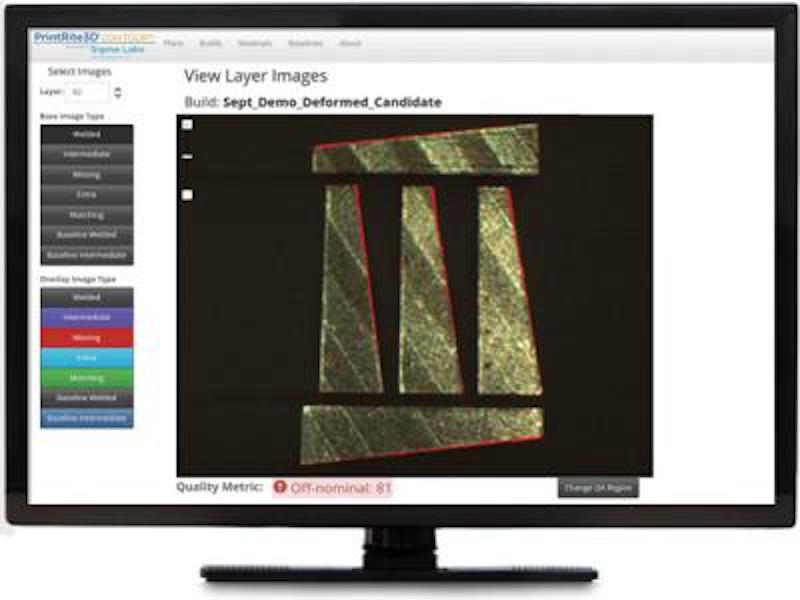

- CONTOUR, which hanldes layer-by-layer geometric measurements

- ANALYTICS, which provides manufacturing intelligence by monitoring operations to build trends and analyses

The PrintRite3D system is “platform independent” and can even provide a “plant wide” quality solution.

It seems to me that if manufacturers are to ever allow 3D printing technologies into the production of end-use parts, they must have a serious quality control system.

But this leads to another question: if quality is a barrier to industry adoption, why don’t the 3D printer manufacturers begin to include quality components, sensors and other equipment directly in their machines to participate in such a system?

Perhaps that’s an improvement we’ll see emerge in future 3D printers.

Via Sigma Labs