Researchers at Purdue University have developed new 3D printing preparation software that could make 3D printing a lot more efficient.

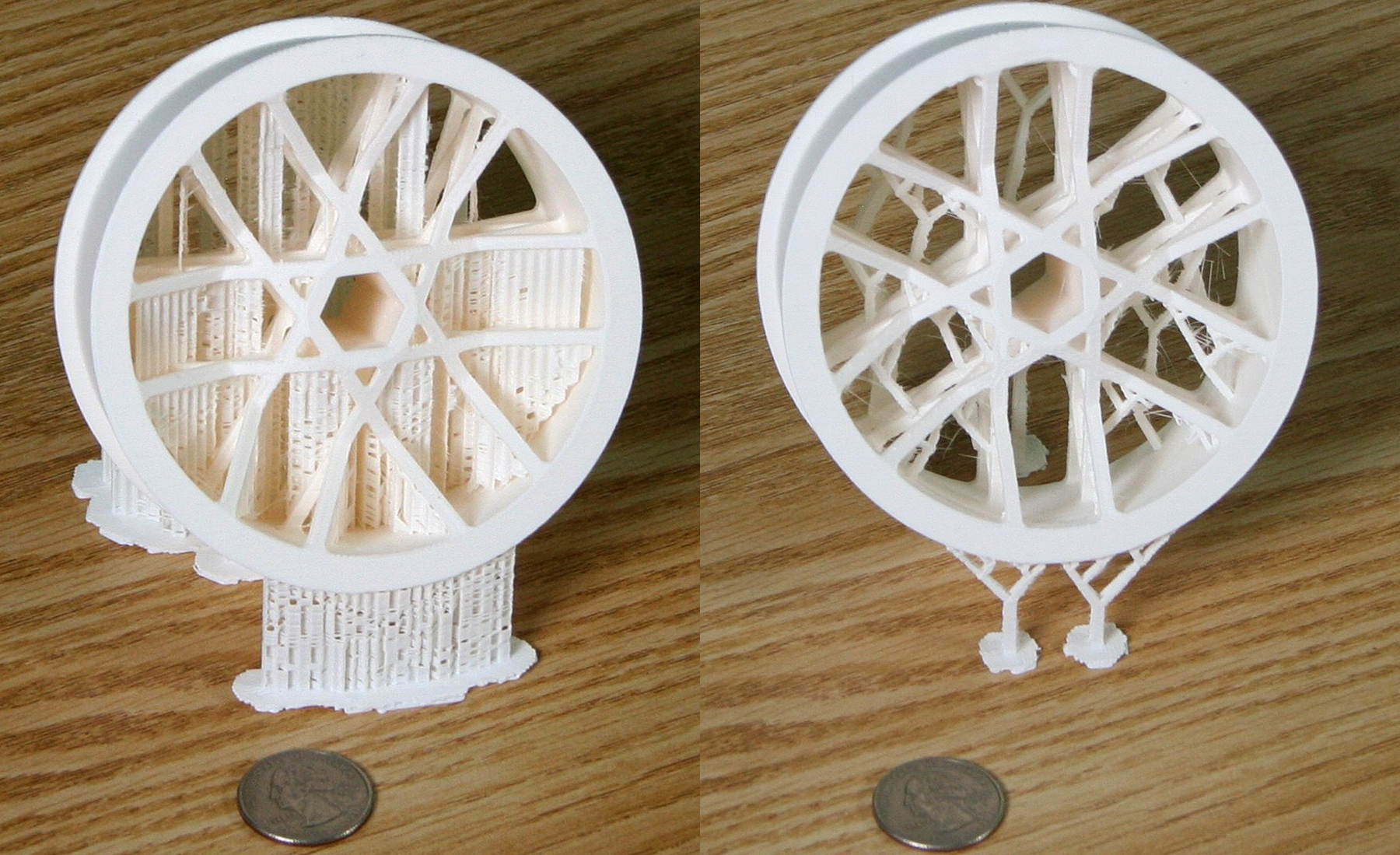

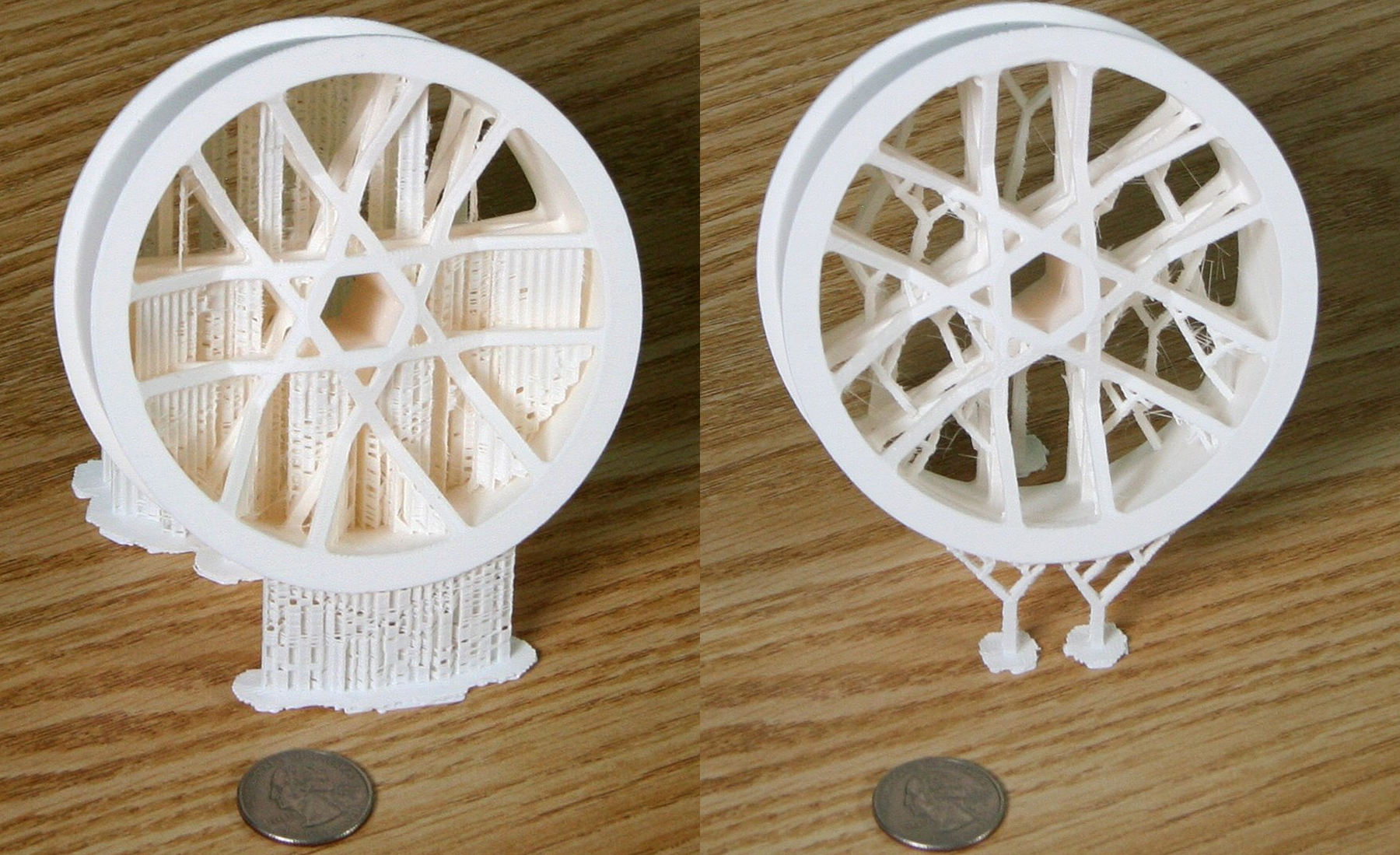

The new algorithm has several benefits. The “PackMerger” algorithm is able to chop up a model into parts efficiently arranged on the print bed. After printing, these parts can be glued together to produce the final object.

There are two big advantages of splitting a model: first, the parts can be split and rotated to minimize the requirement for support material. This not only reduces the amount of material used, but it also could speed printing. Less material to print, faster print.

Another advantage we see is an ability to print objects larger than the build volume of the printer. While this can be done today, splitting models into parts is typically done manually. This software can do it automatically – and lay out the parts for the most efficient print run. Theoretically you could print any object whose volume is less than the printer’s build volume.

The researchers claim an average reduction in print time of around 30% and a material usage decrease of around 40%. We don’t doubt these figures, as it’s easy to imagine piles of support material used for even moderately complex objects created by today’s slicing software.

The question is, when and where will these algorithms become available for everyone to use? Or will they be locked up by a particular vendor?

Via Kurzweil