A new algorithm might prove effective to reduce the amount of support material required for 3D prints by chopping objects into more easily printable shapes.

The method was developed by Ruizhen Hu, Honghua Li, Hao Zhang and Daniel Cohen-Or of Simon Fraser University, Zhejiang University and Tel Aviv University.

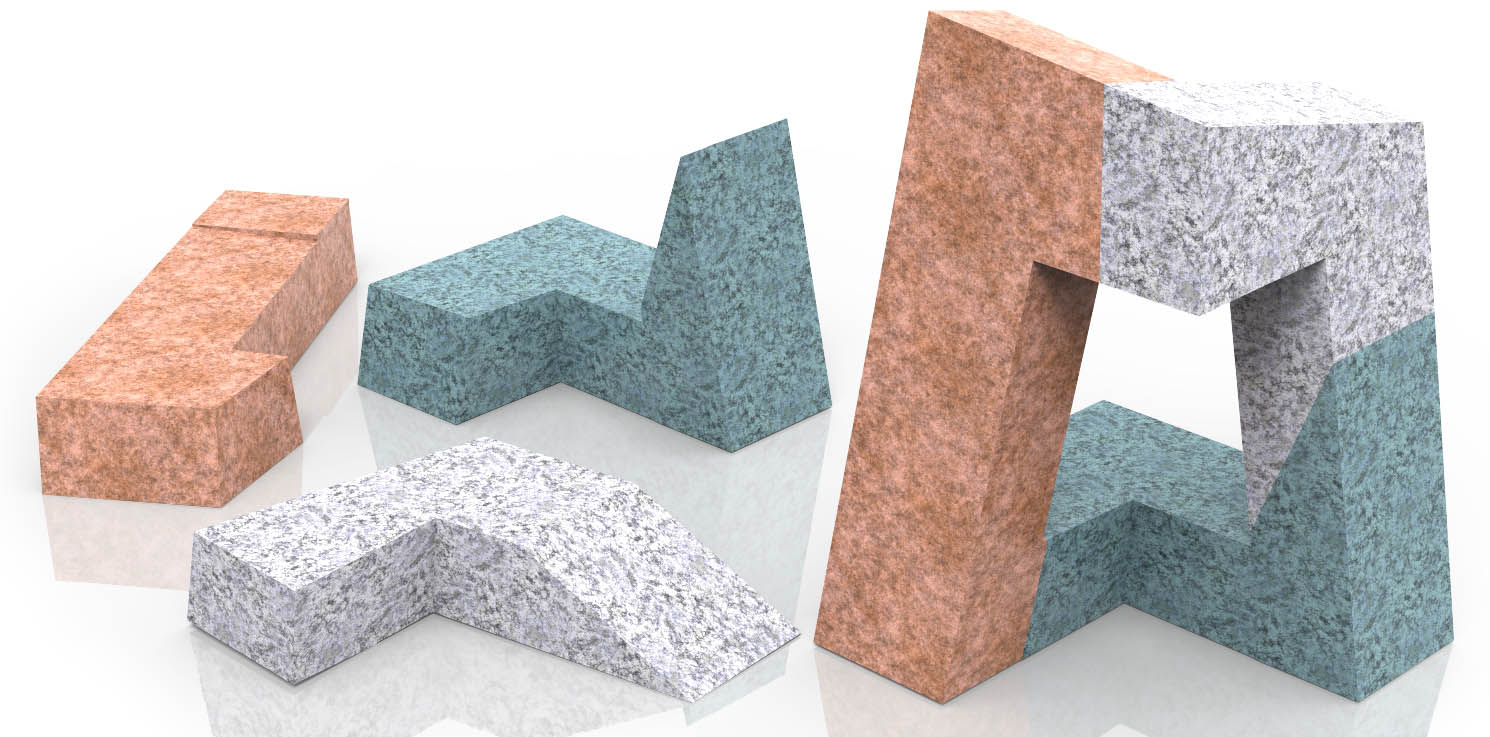

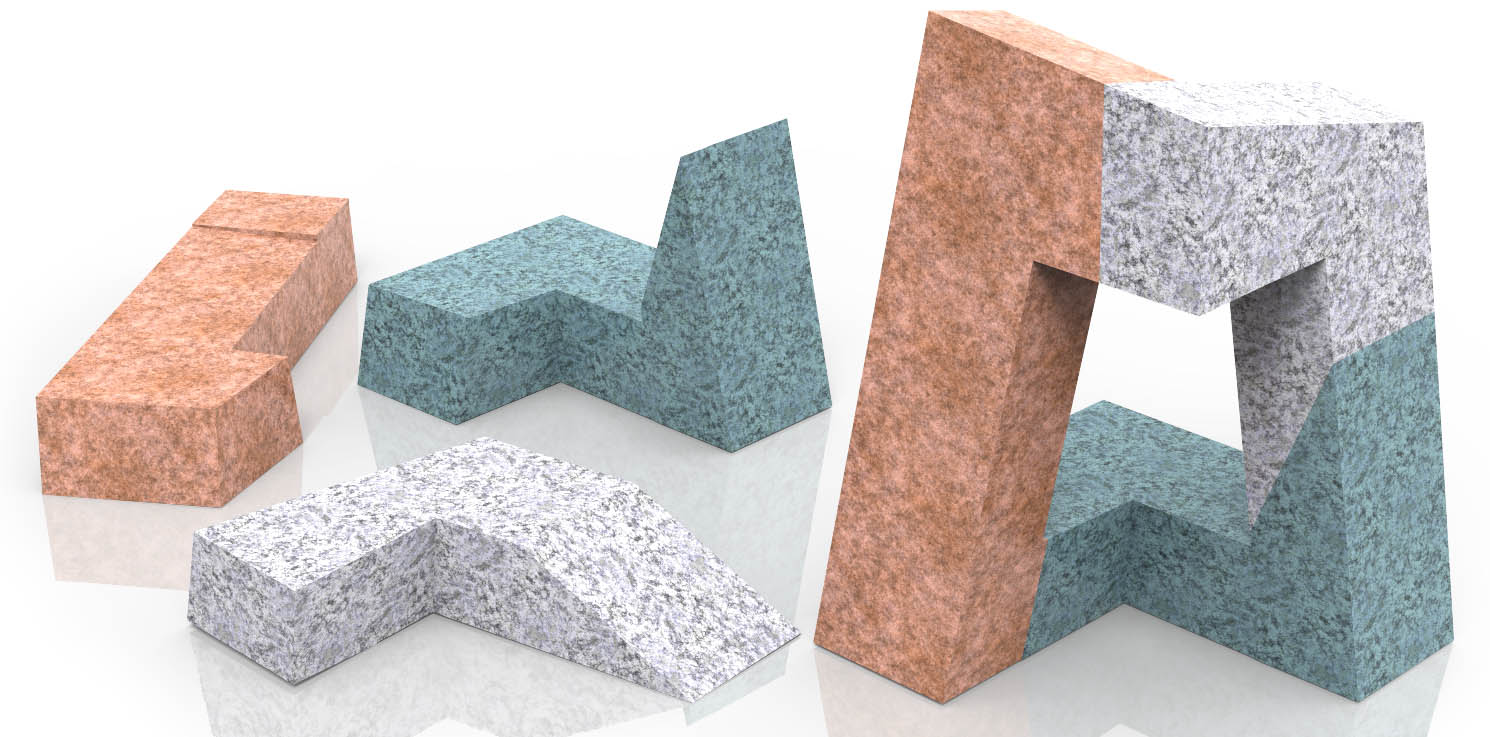

The idea is to decompose a complex object into “pyramidal” shapes, which have no overhangs. Current 3D printers handle overhangs by adding temporary support material that must be removed. This is an incredibly difficult mathematical problem to solve, yet the researchers appear to have done so.

The theory here is that by printing a series of pyramidal shapes without support, they can be reassembled into the final desired object. This avoids the requirement for support material.

But it adds a rather complex step: reassembly. For some objects, reassembly could be significantly challenging. How would one even identify which part is which? A tracking system would be required to label parts and even sequence the assembly process.

In another sense, this approach reduces 3D printing to limitations similar to those found with traditional injection molding, where objects are decomposed into moldable sections and then reassembled afterwards.

We can’t see this approach being successful in the 3D printing universe, as it appears to lose many of the advantages of 3D printing technology if used and also creates potentially significant additional labor requirements.