It seems that NASA has been experimenting with Aerosol Jet 3D printing and their work could leak into other applications.

But wait, what exactly is “aerosol jet printing”? It’s a very specialized process designed by Optomec that isn’t exactly 3D printing, but is extremely complementary to it. Essentially, it’s a method to very precisely deposit electronic ink on 3D surfaces.

Ok, but so what, you ask?

Imagine 3D printing a component. This component can, with aerosol jet printing, have conductive electronic traces pasted freely on all of its surfaces. Or even embedded within the component, if aerosol jet printing is incorporated into conventional 3D printing processes.

This can create a part that is not only structural, but also electronically functional! And, as is the case with regular 3D printing, there are NO geometric constraints on the electronic ink printing. Thus, you can make circuits of ridiculous complexity that occupy virtually no extra space within a component.

Exactly what a space agency might need.

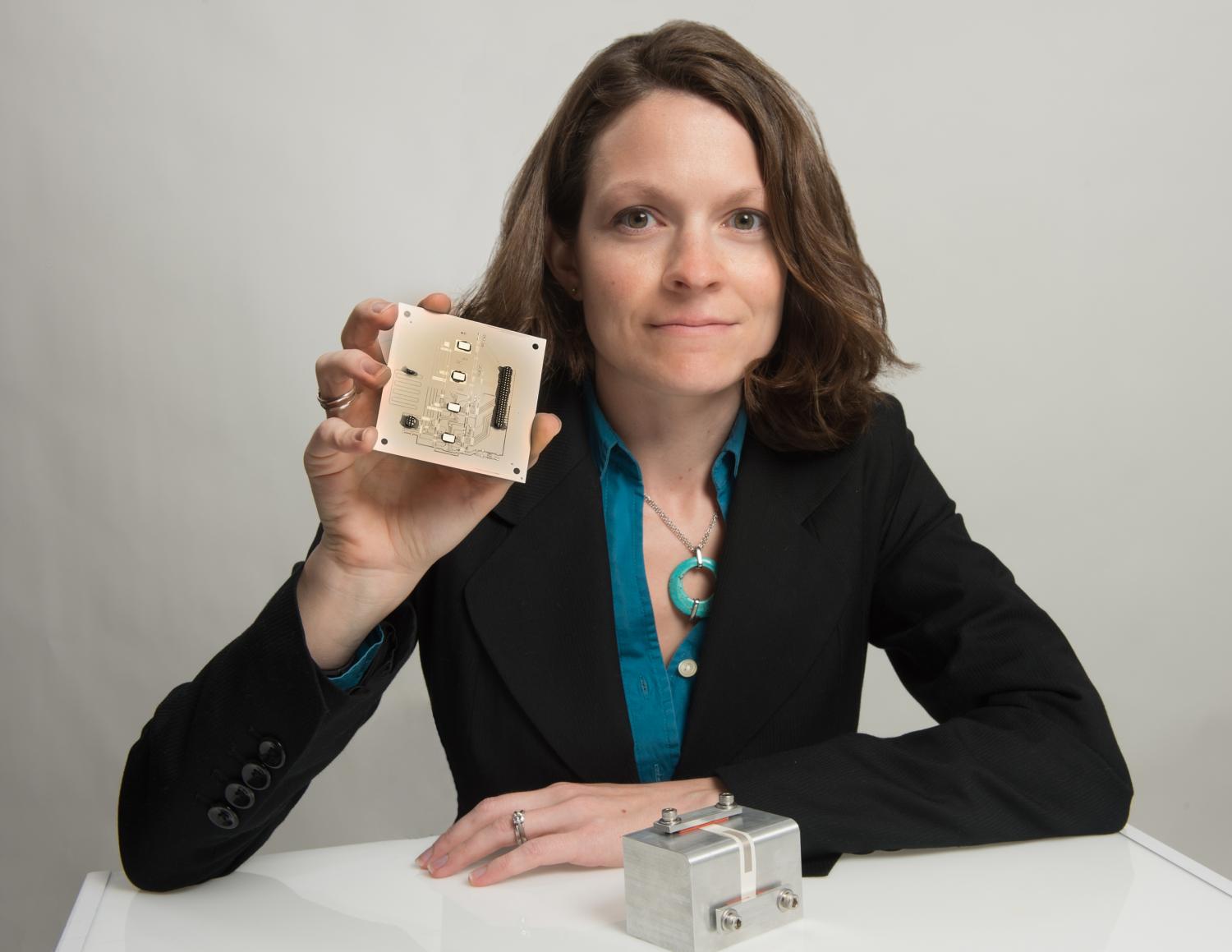

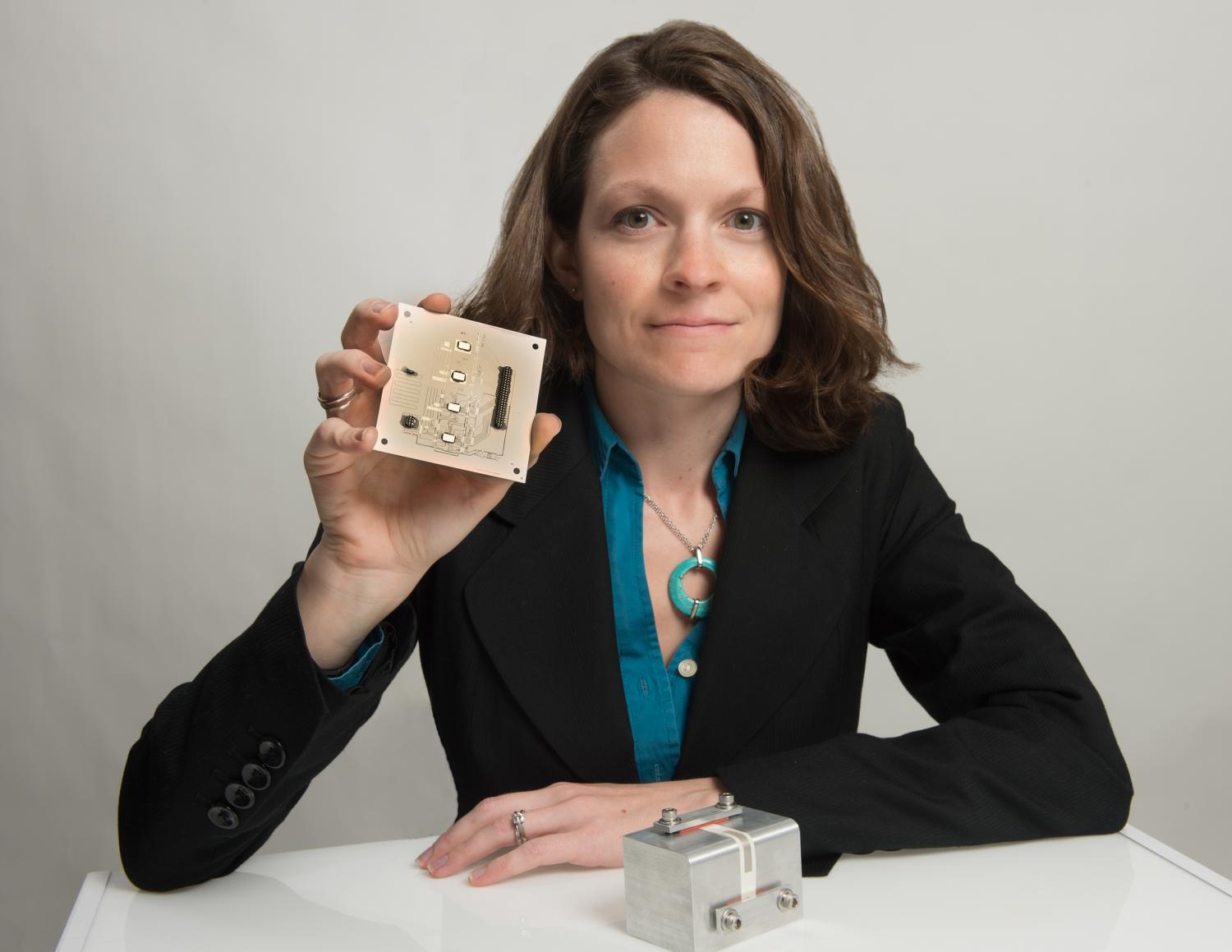

A report on PhysOrg explains that NASA researchers are producing experimental parts in just this manner, as seen in the image at top.

Here’s a sample part that uses the Optomec technology:

That’s all terrific, but I think there’s a lot more to this story. This isn’t just another interesting application of 3D printing. No, this is a notable organization stepping into a 3D printing usage scenario not commonly seen.

Certainly aerospace companies have been experimenting with 3D printing long enough to now regularly produce air-worthy parts with advantages in reliability, simplicity and weight, but they’re usually just an improved shape. These parts typically do not include electronics as described above.

NASA could be showing a way for even more advanced use of 3D printing – with electronics – for the aerospace industry.

Via PhysOrg