Italy-based Roboze has been marketing high-temperature desktop 3D printers for a while, but this experiment may make the prints even better.

High temperature materials are usable in more applications than lower temperature material prints, obviously, but they aren’t metal. The high temperature plastics may be resistant to high temperatures, but can still be vulnerable to other environmental effects such as UV, chemical or other agents.

Their idea is to enhance the high performance 3D printed plastic parts by plating them in metal.

Roboze has partnered with PolyMetal, who offer metal plating experience to perform the experiment.

They’ve performed this experiment with PEEK and carbon fiber, but may have done so with other unusual 3D printed materials as well.

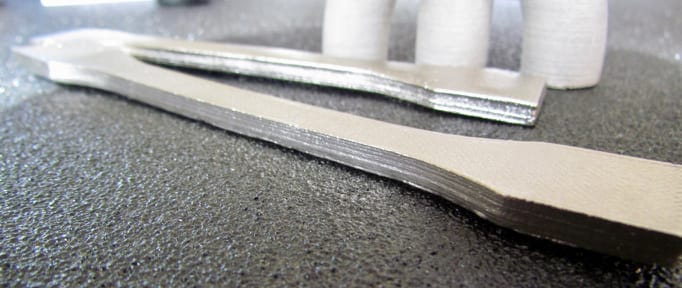

The metal plating process involves establishing a 100 micron nickel or copper layer on the outside surface of the printed part. As seen at top, some parts have had a copper surface applied.

Roboze believes, and so do I, that there are many potential applications for parts produced in this manner. They can be less expensive to make than with true 3D metal printing processes, yet exhibit strength sufficient to meet the needs of some functions.

The metal surface also offers additional protection from some environmental effects, such as UV rays. However, many metals are subject to oxidation.

Metal is also conductive, meaning that such prints can perhaps be used in electrical scenarios.

No, the plated parts are definitely not as strong as true 3D metal printed parts, but they are quite a bit stronger than plastic. You must remember that there is a spectrum of function and an application will fall somewhere along that curve. What Roboze is doing here is simply moving the line a bit further along to capture additional applications.

Expect this to be attempted by other companies, if they haven’t already.

Via Roboze