Researchers at Carnegie Mellon University have developed a computational technique that could solve issues in 3D printing and enable entirely new classes of printed parts.

Everyone is familiar with the telescoping technique, in which a larger cylindrical structure can be made by nesting a series of smaller cylinders. Pulling out the cylinders erects the structure into its final form. It’s a perfect method for storing larger objects in smaller spaces until they are required.

However, it’s hard to imagine shapes other than simple cylindrical shapes. That did not stop the CMU researchers, who realized there had been no systematic study of the types of shapes that could be “telescoped”. And that’s exactly what they did.

The system they’ve developed is truly astonishing, as they’ve apparently developed a method of devising telescoping structures for almost any shape. If that sounds ridiculous and impossible, watch their introductory video:

Essentially they reduce shapes to three dimensional curves on which curvy telescoping cylinders are applied. The curves must be of a particular type in order for this to work, but it seems that most shapes can be approximated by a usable curve.

The research team considered complex arrangements in which multiple telescoping structures are joined together, resulting in a form of collision management in which the shape is slightly tweaked to prevent such incidents.

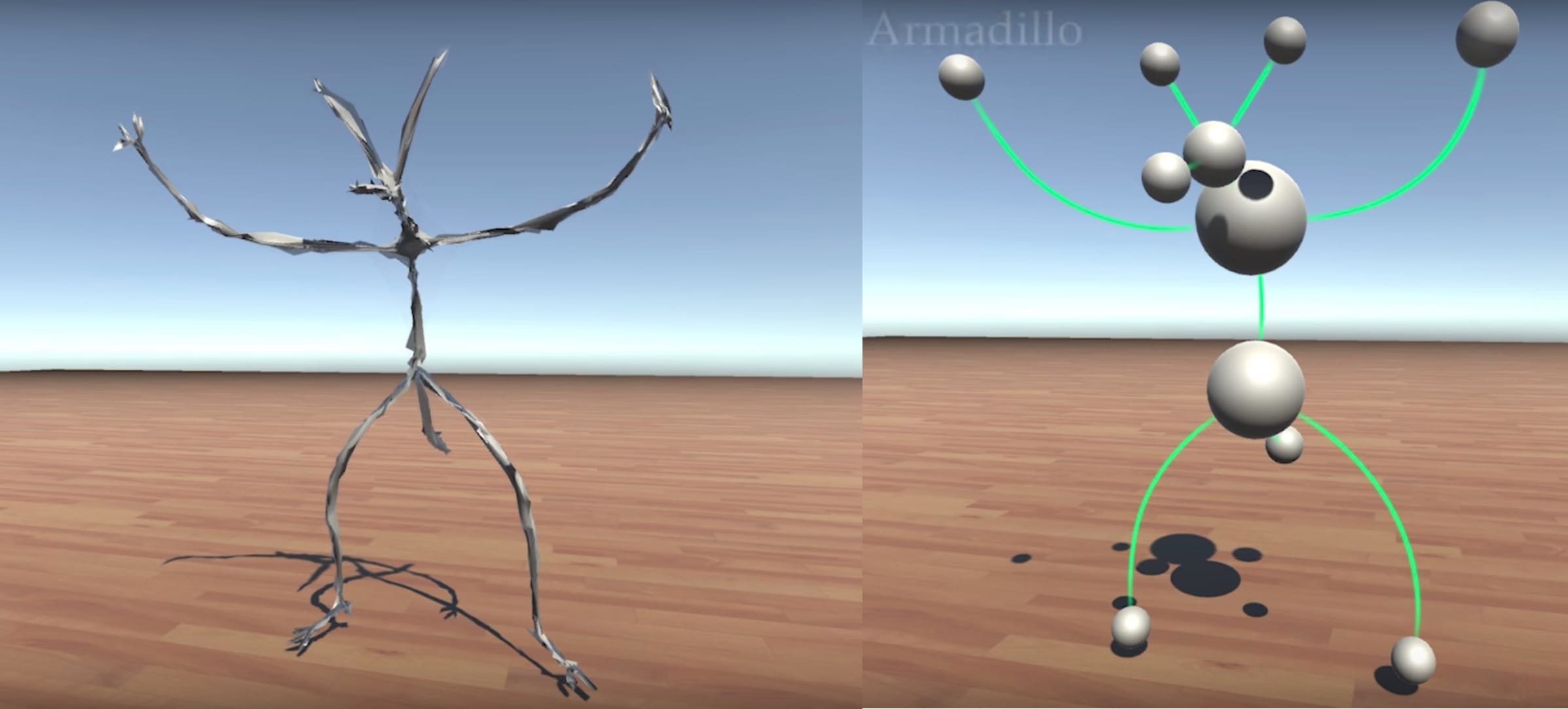

They’ve also been able to take arbitrary shapes and decompose them down to a kind of “skeleton”, which can then be replaced with telescoping-capable curves. From there, the object can be transformed into a telescoped version. Incredible!

They realized that one of these curvy telescope “arms” could actually be positioned easily in any location within reach, much like a conventional robot arm. In a way, they apparently have devised an alternative mechanical approach for robotic mechanisms.

The uses of this approach are quite broad, and generally fall within use patterns requiring small storage and larger active use. This includes shipping, where systems can be collapsed and then expanded afterwards.

Similarly, space-based structures could surely benefit from this, as rocket volume capacity is always at a premium.

Campers will surely benefit from the explosion of collapsible items that could be developed with this technology.

And from 3D printing there are benefits as well. Above you can see an example of a 3D printed telescoping structure computed by their system. What this means is that it could be possible to 3D print objects that are larger than the build volume of the 3D printer being used.

Yes, more material might be used, but the savings in assembly labor and quality control might offset that issue.

I’m looking forward to seeing more of this technology, particularly if it is included in CAD systems for easier development of telescoping objects.