Some things are difficult to explain without a visual aid, but that’s not an option for people who are blind.

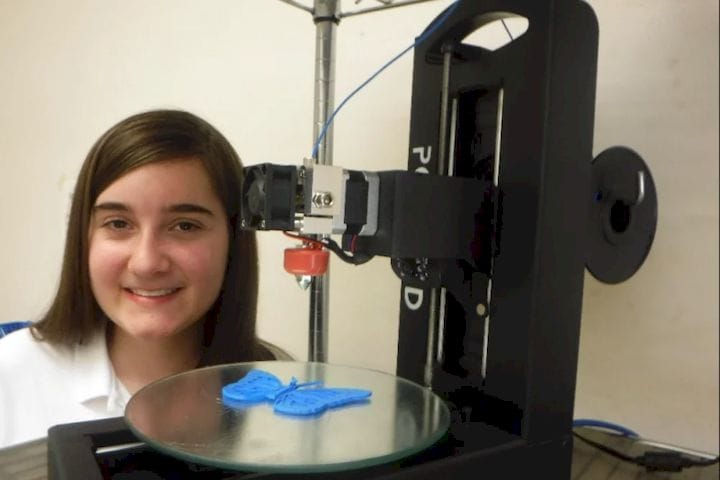

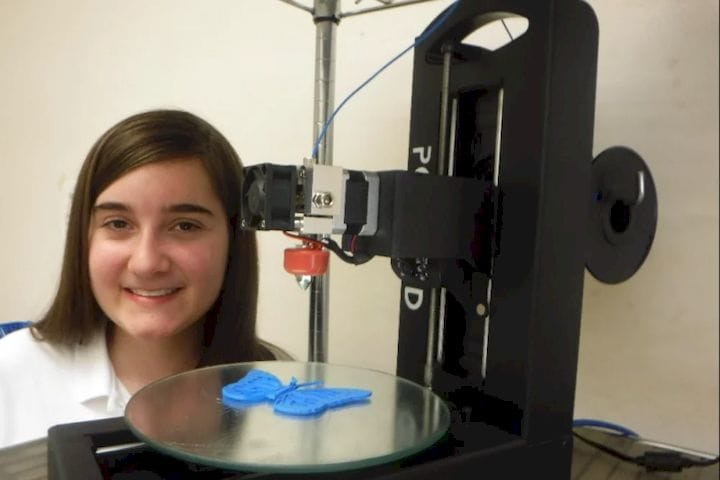

The challenge in helping this population is to develop tactile “visuals” that are complicated enough to be useful while inexpensive enough to be practical. In a recent TEDx talk, recent highschool graduate Caroline Karbowski explained how her organization See3D is accomplishing just that, with 3D printing.

In her talk, Karbowski explained how her project began with a childhood interest in Braille, and an article she read about people 3Dprinting models of telescopes and microscopes.

When Karbowski started attending high school, she noticed that her school’s 3D printers were going unused and that large student projects meant that filament remnant colors were just sitting around. And when she met her friend Cassandra, who is blind, the pieces came together.

Karbowski3D printed a model of a castle for Cassandra. “I asked her, ‘How would you describe a castle?’” Karbowski remembered. “And she said, ‘I can now feel the turrets. I can feel the walkways and the doorways. I have a more clear and vivid image of what ‘castle’ means. Before I touched the model, castle was just a word.’ And I thought, we need to make concepts more than just words.” She started exploring how she could helpforge connections between visually impaired people and sighted people who would be interested in 3D printing models for them.

Karbowski named her project See3D, and created a website with the help of several friends. Blind and visually impaired people could send in requests for item models, and sighted people who were enthusiastic about 3Dprinting could print them off and send them to See3D’s address. The project became her school’s 2016 Tech Olympics Showcase project, and won the school a grant that provided filaments, printers and 3DP software.

Now, See3D operates both in the U.S. and internationally. Its models have been incredibly useful, especially to students. While tactile models existed pre-3DP, they have historically been large and expensive, meaning that students generally can’t take them home to study. In contrast, 3D-printed models are relatively inexpensive, and they can be printed in many different sizes.

One intriguing possibility that Karbowski discussed during her talk was that you could 3D print small models of an item to allow people to get the “big picture,” then print larger versions to enable people to examine items in finer detail afterward. So far, the most popular items include tiny objects like cells and protein carrier molecules, as well as much larger ones such as castles and The Statue of Liberty.

Read more at ENGINEERING.com

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.