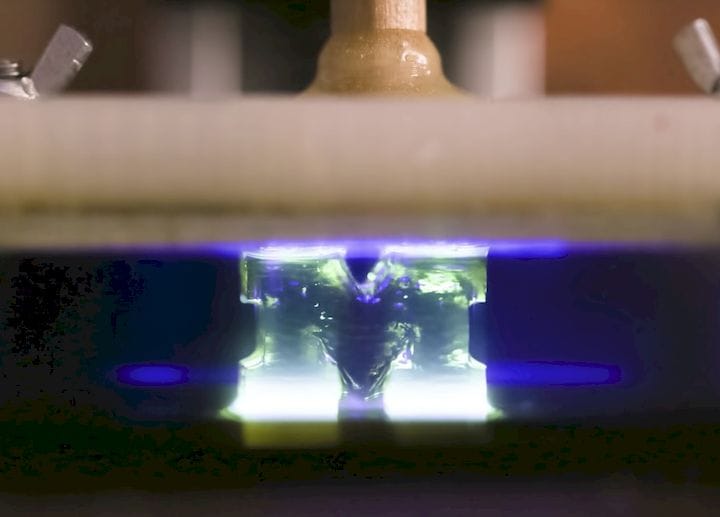

![A new process for 3D printing in resin [Source: UMich]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ec6e38fc.jpg)

Researchers at the University of Michigan have developed an extremely interesting 3D printing process that is quite different from current approaches.

The researchers sought to eliminate one of the most pervasive problems when 3D printing photopolymer resin: window adhesion. This occurs when the light engine solidifies liquid material at the bottom of the resin tank through a transparent window. The problem is that the newly solidified material also sticks to the window itself, necessitating special action.

Earlier resin 3D printers simply stopped printing and made the machine perform a mechanical maneuver to rip the fresh layer off the tank, then allow fresh liquid resin to flow in and repeat the process for the next layer. This works, but drastically slows printing because the layer “peel” maneuver is very time consuming. Even worse, the window transparency gradually degrades and messes with the print accuracy, requiring tank replacement or refurbishment.

Several 3D printer manufacturers have attempted to get around this effect by producing a resin tank window that doesn’t stick as much. This is done by sophisticated coatings by most, but Carbon’s unique approach is to use a window that permits oxygen to permeate. The oxygen prevents the resin from solidifying, essentially eliminating adhesion.

But that doesn’t completely solve the problem, as fresh liquid resin must move into the new layer space once the platform is raised by one layer’s thickness. The new problem is resin flow: these adhesion solutions only provide a minuscule area to be used for new resin flow.

The implication is that the resin must be quite watery in order to flow into the thin space in a reasonable time for printing to proceed. However, that creates constraints on the nature of the resin itself. Watery resins tend to produce parts of lesser strength; if materials for rigidity were added they could contribute to increased viscosity.

They say:

“The thickness of this polymerization inhibition volume adjacent to the projection window is a critical parameter for continuous stereolithographic fabrication. Previously reported inhibition layers resulting from oxygen inhibition are typically only tens of micrometers thick. Although this inhibition layer eliminates adhesion to the window, its small thickness curtails resin reflow underneath the emergent object, especially in objects with large cross-sectional areas, and necessitates the use of low-viscosity resins or fabrication of objects with small cross sections.”

This is the problem the researchers were solving, and their solution is amazing.

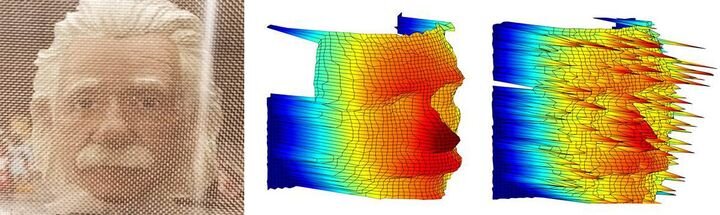

![The dual-light resin 3D printing process [Source: ScienceMag]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ec78e3fb.jpg)

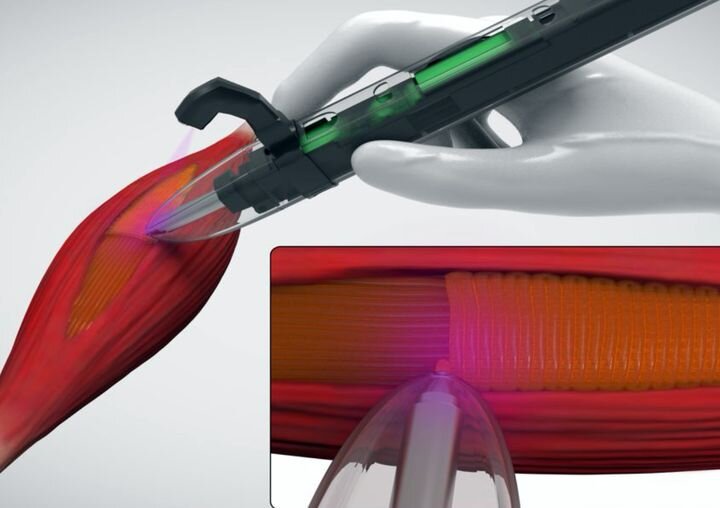

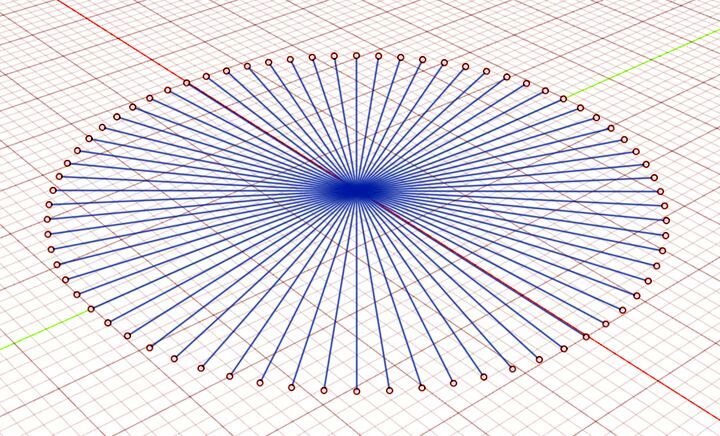

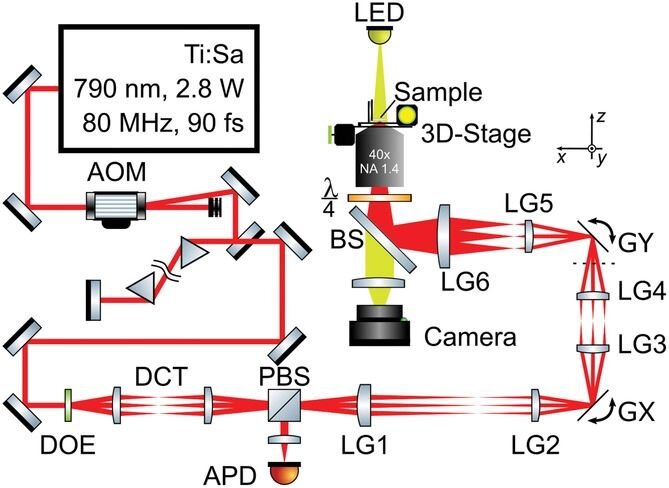

Their printing process includes the usual light sources to perform solidification – but also includes a secondary light engine to prevent solidification.

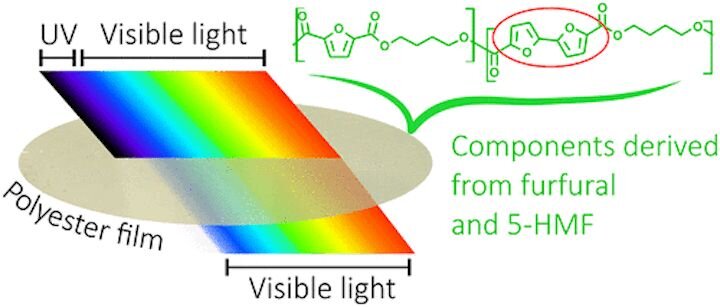

They’ve created a photopolymer resin that has two reactions: solidification if exposed to one wavelength, and inhibit solidification if exposed to a secondary wavelength.

Using this light engine capability they constructed a 3D printer that used the secondary light engine to create a “huge” gap between the resin tank window and the area of solidification, said to be millimeters in size, far greater than the near microscopic layers of other approaches.

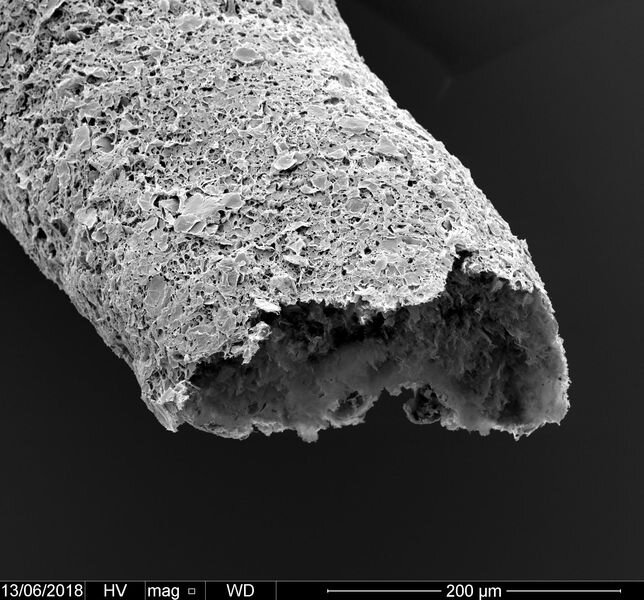

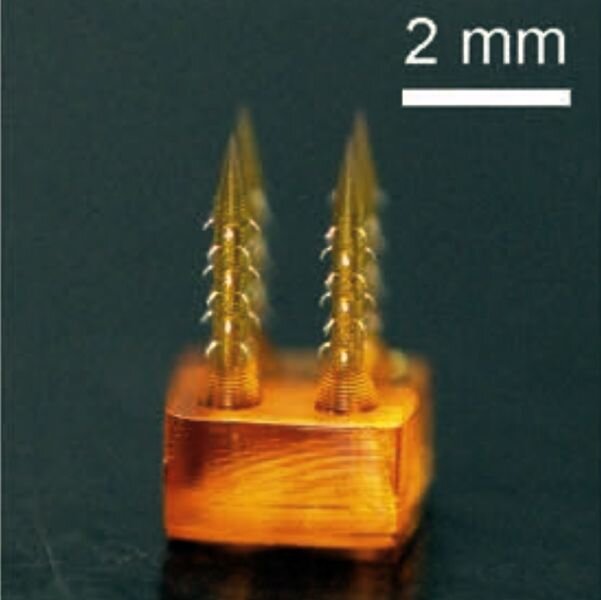

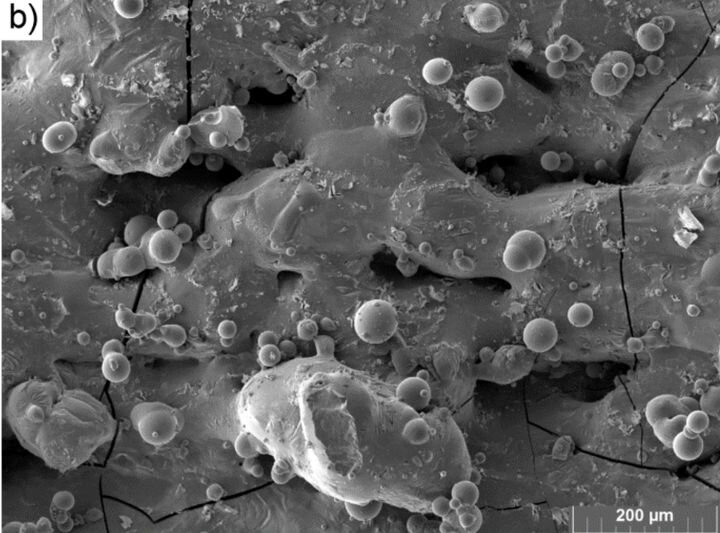

![3D print samples using the new dual-light printing process [Source: ScienceMag]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ec7dd81d.jpg)

This means their process can 3D print at much higher speed — not only because they don’t require a peel process, but also because they don’t have to wait very long for the fresh resin to flow inwards. Their print speeds should be more or less consistent per layer regardless of the printed object’s geometry – which is NOT true with the other speedy resin 3D printing solutions.

Here you can see a video showing a print from the new process, which, even though it is sped up 6x, is still impressive:

How fast can this process print? Incredibly, the researchers produced a device that can print 2 METERS in height each hour. And this would no doubt be only a proof of concept device that could likely be optimized for further speed improvements.

They say that the process uses photoinhibitors that are compatible with major types of photopolymer resin, making the material types usable in this process quite broad.

The implications of this discovery are quite significant.

First, added speed of 3D printing will certainly resonate with those considering the method for production uses. Current 3D printing processes, even the most speedy ones, are still quite slow when compared to traditional manufacturing processes.

Secondly, the ability to use more interesting materials in resin 3D printing will also attract those seeking unusual production uses.

Apparently the researchers have (unsurprisingly) patented the process, and are seeking to develop a startup company to commercialize the process. I suspect they will easily receive considerable funding to proceed and in a couple of years might rival Carbon.

Finally, I’m wondering if the revelation of two-light source resin 3D printing might generate even more processes than simply inhibiting the bottom layer solidification. What if beams of solidification and non-solidification were angled through the resin tank? Could you 3D print, “in 3D”?

We will soon see.

Via UMich and ScienceMag

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.