![Shock wave-proof 3D printed surfaces [Source: Wright-Patterson AFB]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097c9533dd.jpg)

The US Military has devised a unique method of 3D printing a surface resistant to shock waves.

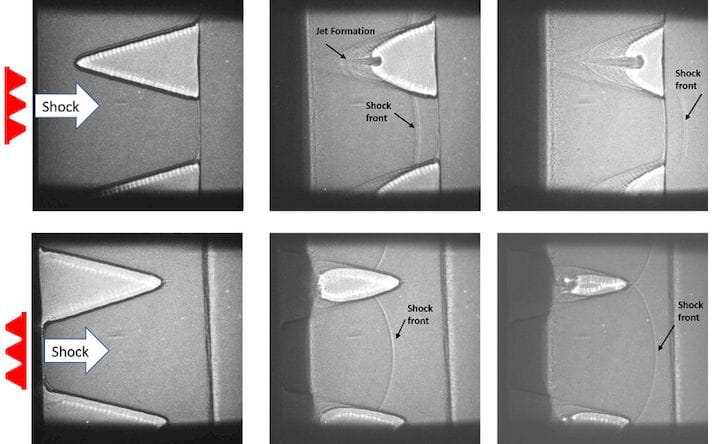

The design, produced by the Air Force Research Laboratory (AFRL), involves 3D printing microstructures that are shaped to absorb shock waves.

The applications for such a material are obvious in the military, which must deal with explosive shock waves on a variety of different equipment. If there were ways to reduce the shock effects, then equipment could be kept operational longer during encounters.

The AFRL team has been using computer simulations to identify promising designs, which are essentially small holes in a surface. The aggregation of these cone-like holes makes the substance take on a foam-like appearance. Designs of particular utility in simulations would be 3D printed and tested in live environments.

But how does it work? They explain:

“When these cones encounter a shock wave, they collapse inward, forming jet protrusions that project from the opposite side. These jets localize the shock wave energy, which is the origin of the material’s unique directional behavior.”

Thus far the experiments are being 3D printed at rather small scales, under a centimeter in size. However, the researchers are quite hopeful that the technology could be scaled up significantly.

One can imagine panels with this type of surface being 3D printed and then applied to the side of devices requiring additional protection. Note that shock wave protection need not be restricted to vehicles or weapons; it could also find significantly valuable usage in adding protection to static infrastructure, such as communication relays, etc, which might otherwise be disabled by nearby mild explosions.

I am impressed by this development, as it shows there are countless new designs yet to be discovered that leverage the new properties making enabled by 3D printing. For too long we have had our design heads stuck in the baggage of old design approaches that were constrained by traditional making techniques.

Now that’s beginning to change.

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.