It has been proven: a rudimentary 3D printer has been built solely from mechanical components – with no electronics involved.

Dutch artist and maker Daniel de Bruin created this startling mechanical creature he calls “this new technology” as a work of art. He says:

3d printing allows me to create products more swiftly and more efficiently than ever. but these products are not mine. they are merely a product of this new technology. I love technology but how can I reclaim ownership of my work? perhaps by building the machine that produces the work. perhaps by physically powering the machine, which I built, that produces the work. in hopes of rediscovering the sense of having created something, I create.

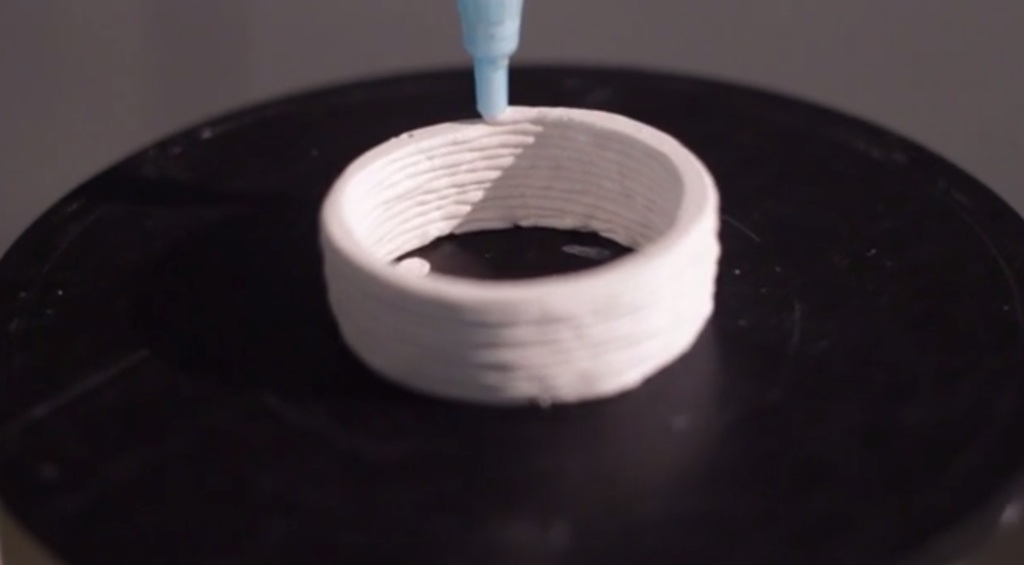

The machine operates by gravity. Some 15kg of metal weights pull a chain that powers all the moving parts of the machine, including the extruder, speed governor, z-axis and print plate spinner. Wait a sec, what are those? The speed governor appears to be a fan-like structure in the rear that uses air resistance to moderate the speed of the machine. The plate spinner, well, spins the print plate, eliminating the need for old-fashioned X and Y axis movements.

You might ask how the machine knows what to print, as there are no electronics to read SD cards, no WiFi to listen for GCODE streams. Instead, the “3D model” is in fact a simple aluminum wire from which the diameter of each layer is read in an analog fashion. Bending the wire provides a different shape. It’s much like a “Lathe” tool found in 3D modeling software, except this one is in real life!

Material options on this machine seem to be limited to room-temperature squishy stuff, as the extruder is a syringe driven by the limited force of gravity.

This design is never going to show up in people’s homes or workshops, but it does demonstrate the possibilities of analog design.

Via Daniel de Bruin