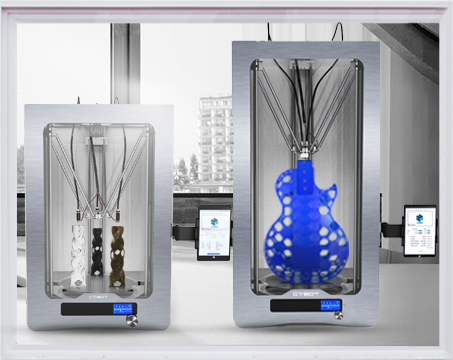

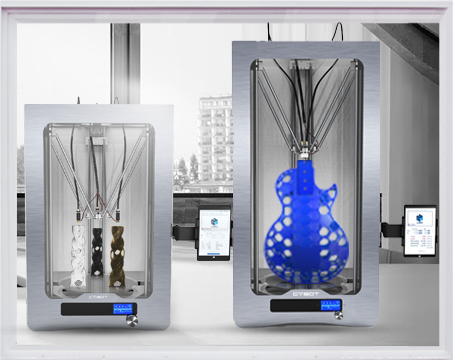

We had a chat with the producers of the upcoming Cybot 330 PRO desktop 3D printer to find out more about the mysterious device.

The company’s website doesn’t seem to tell the whole story, but this machine appears quite interesting. First, here’s that main features you can find out publicly about the machine:

- It’s a delta-style machine with a very generous build volume of 330 x 330 (cylindrical volume).

- It can print layers as small as 0.05mm – with a new “HD” version able to hit 0.025mm – and double height, too!

- It handles a variety of plastic filaments, including the higher temperature materials Nylon, PEEK and Polycarbonate in its sealed chamber. In all, the machine is said to support over 30 different materials.

- It apparently can print at speeds up to 400mm/s, with up to 900mm/s on the HD machine. There’s even a hint of being able to run at a stupefying 3,000mm/s.

- There’s some kind of self-leveling feature.

- Pricing is listed as “$1XXX” for the PRO version.

Well, that was enough mystery for us so we asked Cybot some direct questions about this machine:

Fabbaloo: What is the actual retail price? Your site says “$1xxx”. What currency is this? Is this retail or distributor price? Are we talking $1,100 or $1,999?

Cybot3D: Final MRSP price of the Cybot 330 PRO will be closer to $1900 in today USD. Our distribution partners in North American are positioning the Cybot 330 PRO in the league of large format 3D Printers such as Ultimaker 2 Extended, Delta WASP 20×40, and the upcoming 2016 Makerbot Replicator GEN 6.

As you can notice that besides being a full metal chassis machine, the Cybot 330 PRO will come standard with a stand-alone WiFi enabled touch controller that promises to bring the best touch and print experience for the user. And we believe consumers will hardly find alternative 2016 machine model that offers similar comfort and features / ratio.

Fabbaloo: When are you expecting the device to be available for sale? This year? Next year? Can you give us a hint?

Cybot3D: In the US and Canada, the Cybot 330 PRO will be available for sale in October of this year on our official web store, iMakr store, and Amazon.

Fabbaloo: Can you explain how the self-leveling is accomplished? It appears that you are dynamically adjusting the Z-height during printing to account for tilt?

Cybot3D: The machine uses high quality capacitive proximity sensor such as Z-Probing to detect and automatically adjust the Z-height for self- calibrating.

The printing glass plate is also designed to be used as a 3D scanning rotatory that works with RealSense Color 3D Sensor and other open sourced scanning devices.

Fabbaloo: What is the normal, practical print speed on the device? 3000mm/s is likely only for some non-printing travel moments.

Cybot3D: We recommend using high quality filament brand to archive high speed printing. Our high speed printing setting mode will have large partial portion of the object to be printed at 340mm/s (extrusion rate), but advanced users can increase the speed by following our power-user instruction.

Unlike most other 3D Printers in the market today, Cybot machines use high speed bearings (like those found in motorcycles) and a rigid stainless steel chassis to ensure performance and durability of the sliding mechanism system. We are also invested heavily in R&D of our all metal feeding extruder that promise to bring more speed and can be an easily upgrade module to improve productivity.

Fabbaloo: What filament dimension is used? 1.75mm?

Cybot3D: Default filament feeding size for our extruder is 1.75mm, but we do offer upgrade option for 3.00mm filament.

Fabbaloo: Will you be selling directly from the website, or are you looking for distributors?

Cybot3D: Currently, we have a lot of interest from local and US educational equipment distributors to sell the machine. There will be an All-in-one 3D Printing & Scanning Cybot 330 Enterprise model that focus heavily on business and large corporation that we will Introduce to worldwide distributors after the release of Cybot 330 PRO.

Fabbaloo: Finally, who are you guys? Where are you located? How big is your team? What inspired you to build this printer?

Cybot3D: Our main office is located in Vancouver, BC, Canada. We have 42 technical staffs specialized in consulting and have maintained industrial manufacturing equipment for more than 10 years. The Cybot3D 3D Printer Brand is the collaboration result of the company with our CNC Machining Metal Parts Supplier.

Cybot 3D will also be one of the first firms to provide solution to boost productivity of mass 3D printing such as multi-object parallel extrusion of up to 3 object at the same time and external convey table module that are found in CNC machines.

We believe large 3D printed parts is the future of 3D printing and they should be made from wide range of materials for engineering and ergonomic purpose of large objects that require multiple assemblies, high cost of tooling, and long production startup time.

Via Cybot3D