It takes a lot to make a splash in the world of desktop 3D printers these days, with fierce competition from all sides. The new N-Series from Raise3D is going to make a big splash. Or two.

Raise3D is a company based in Pasadena, California and Shanghai, but seems to have benefited from several generations of Asian 3D print manufacturing experience, which originally evolved from the open source RepRap and MakerBot projects.

With a never ending parade of highly similar new consumer and prosumer 3D printers hitting the market over the last year, it’s refreshing to see a new product quickly become a “must have” item among the hardcore 3D printing community.

Sometimes Chinese manufactures can be viewed with skepticism, but Raise3D is derived from a lineage of developers and engineers with considerable experience in the field, which seems to have largely overcome the typical skepticism.

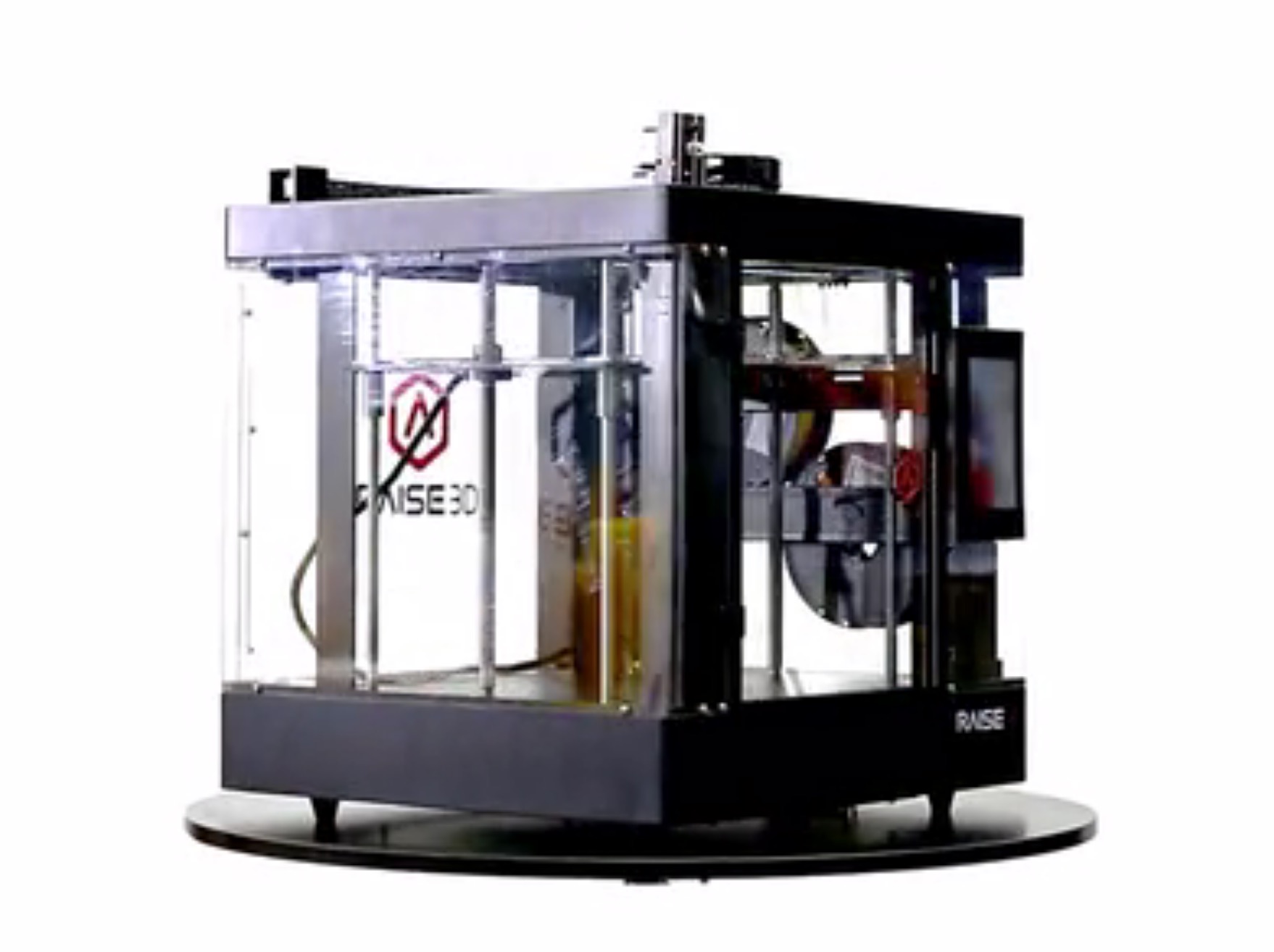

But let’s take a closer look at why Raise3D’s N-Series has garnered such interest. While it includes the now defacto standard features of: a full-sized, 7-inch full-colored touch-screen with an easy-to-use interface; heated print surface; an all-metal hot-end that can operate up to +300C, meaning it can print almost any 3D print material; Dual extruders; Network connectivity for remote operation; a fully enclosed print chamber for temperature moderation; and more, there are several significant innovations that make this line of 3D printers quite different from most of the competition:

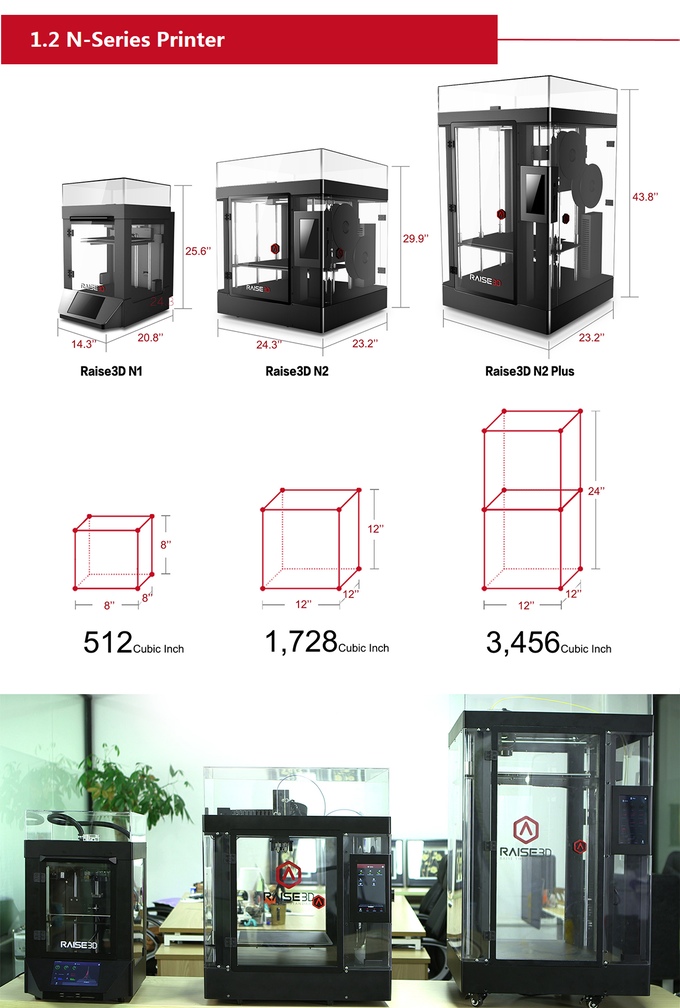

Huge build volume: 203 x 203 x 203mm (N1), 305 x 305 x 305mm (N2), and a truly massive 305 x 305 x 610mm. That’s taller than many delta 3D printers!

Power interruption recovery: You can literally resume printing after a power failure. The N-Series detects power loss and saves the state of the machine so that it can restart upon power restoration. This is particularly important for the long print jobs that will take place on these huge machines.

Onboard computing: The N-Series includes a Quad-Core 1Ghz ARM processor with 8GB internal memory storage and 16 GPIO ports can provide incredible real-time dashboard information (including a visual view of print progress), as well as managing print queues and visual maintenance aids.

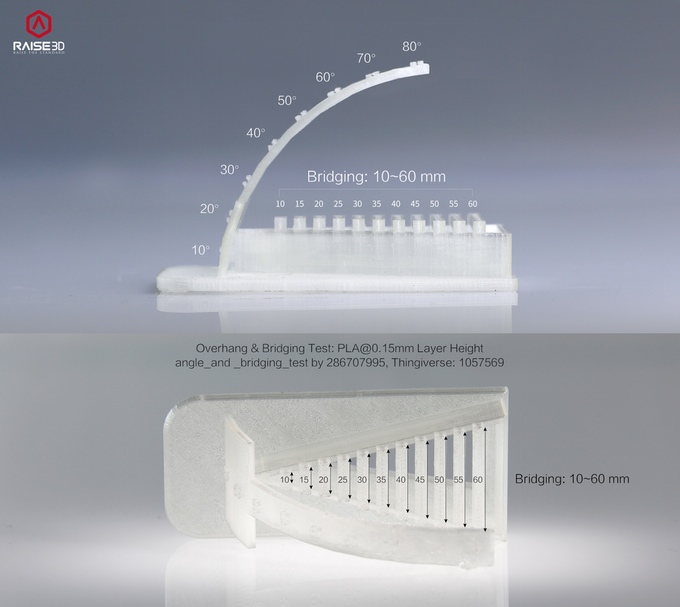

Superb print quality: Based on the documentation we’ve seen, particularly the images of sample prints, the print quality is spectacular. Their specs boast layer sizes of 0.010 to 0.025mm layers, far smaller than typical 0.100mm of other plastic extrusion machines. Here we see an image of a very nicely formed print. The print quality is derived from high-quality components and careful engineering.

This shot of an overhang and bridging test on the N-Series. Is this even possible? We’ve never seen a machine execute an 80 degree overhang. More than likely, this print took considerable tuning of print parameters. Please take a very close look at the images on their Kickstarter page and prepare to be amazed.

Pre-Leveled: The N2 machines include a specially designed build surface that is “pre-leveled” at the factory and does not require any subsequent adjustment. The borosilicate glass surface is also covered with BuildTak to aid adhesion.

Three form factors: The N-Series is actually made up of three separate, but similar machines. The “baby” machine is the N1, with the smallest build volume of the family. The N2 and N2 Plus adds the pre-leveled platform, but the machines are otherwise similar.

Software: Their “IdeaMaker” slicing software can use its network integration to operate the N-Series remotely. It has features similar to other slicing engines, except for two additional integrated features: Advanced “Free Cut” and “File Repair”, which should prove quite useful.

Their crowdfunding launch has already been hugely successful, with pledges vastly outstripping their campaign goals, so we can expect this project to proceed.

For now, you can pre-order an N1 for only USD$1,199, with the more popular N2 priced at USD$1,749. The huge N2 Plus is priced at a very reasonable USD$2,199, far less than competing large-form factor 3D printers.

Via Kickstarter and Raise3D

Duplicat, aka: Gene Crady of Indiana, USA, is a 3D Creative Technologist, and FDM/FFF Additive Manufacturing Specialist and owner of Duplicat 3D Printer Services.

Fabbaloo founder/editor Kerry Stevenson, a.k.a. “General Fabb” has been writing and exploring 3D printing with Fabbaloo since 2007.