If there ever was a 3D printer that bridges the gap between expensive industrial 3D printers and inexpensive desktop machines, the AON is it.

The story of Canada-based AON is familiar: some folks involved in 3D printing experienced issues, and they set about to solve them by making their own product. In AON’s case, they were a 3D print service bureau, providing prints to those without printing equipment. But they found that:

We were limited by size, frustrated by the high failure rates of dual extrusion, and could not combat warping and cracking in large prints with useful engineering plastics.

For many desktop 3D printer owners, this is the case: the major reason PLA plastic is so popular is that it tends to print successfully, whereas other materials can be problematic or require additional printer features. That changes with AON’s first 3D printer, and it’s quite a machine.

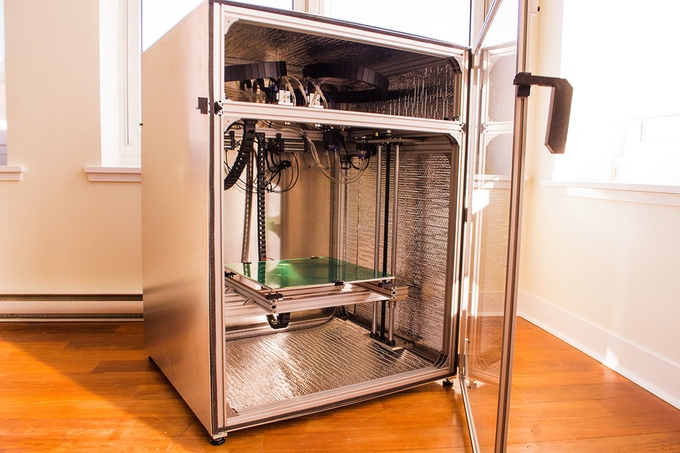

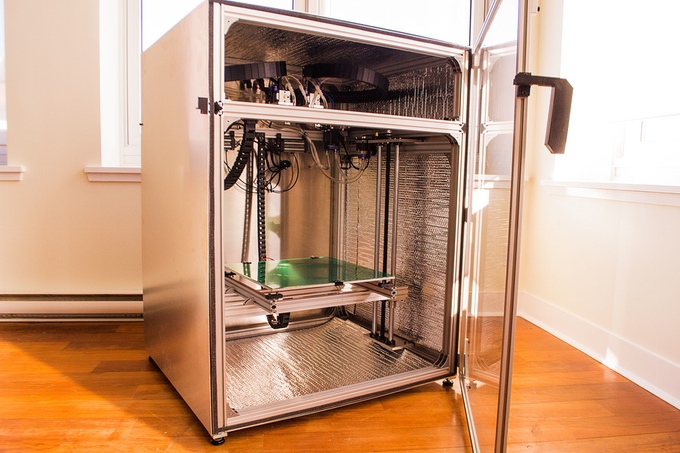

They’ve engineered the device specifically to be able to produce large-format, high-quality results in a wide variety of engineering-quality plastics. Here are the highlights, as we see them:

The massive build volume of 450 x 450 x 640mm is not the largest you can buy, but it is far larger than typical machines at this price point. The AON can also print layers with 0.05mm height, and includes a WiFi network interface. Check out the size of this machine with a person beside it here:

AON recognizes one of the issues facing those with large prints: extremely long print times. They’ve therefore included a number of different swappable nozzle sizes. The default is 0.6mm, larger than the standard 0.4mm you’d find in most other 3D printers. Also available are 0.4, 0.8, 1.0 and a huge 1.2mm nozzles.

Most notably they’ve solved one of the rudest problems in 3D printing: interference from the second extruder. A second extruder is frequently necessary when printing complex objects for providing support material, but the typical arrangement is to pair the two extruders together on the gantry. This means the “other” extruder passes over the print in progress. Normally this is inconsequential, but in the case where a slight mis-extrusion causes a bit of material to be above the current print layer, the second extruder can come in contact with it and risk print failure.

AON solves this problem by making the second extruder completely independent! If not used for support material, it simply parks itself on the side, far away from active printing. Here’s how it works:

This second extruder approach also provides an ability to print two objects simultaneously, if they are sufficiently small and separated on the build platform. That should not be an issue with the ridiculous size of the AON 3D printer.

For printing engineering-grade plastics, the machine includes a heated print surface, but they’ve gone beyond that. Far beyond:

But we didn’t just slap some acrylic paneling on the sides and called it a day. Up to 1800W of chamber-heating power keeps the interior nice and toasty (rated up to 70C).

This should definitely provide a significant boost to the reliability and ability to print large objects in plastics such as ABS, although it appears this is an optional feature.

In fact, this approach is precisely what’s done by Stratasys in their FDM equipment: the chamber is heated, coincidentally, to the same temperatures to avoid warping. And it works very well for them, so it should work the same for AON’s machine.

But this leads us to the question of patents. Our understanding is that Stratasys still claims the right to use of temperature controlled build chambers, so it remains to be seen whether they will challenge AON on this feature. Perhaps that’s one reason why it’s optional?

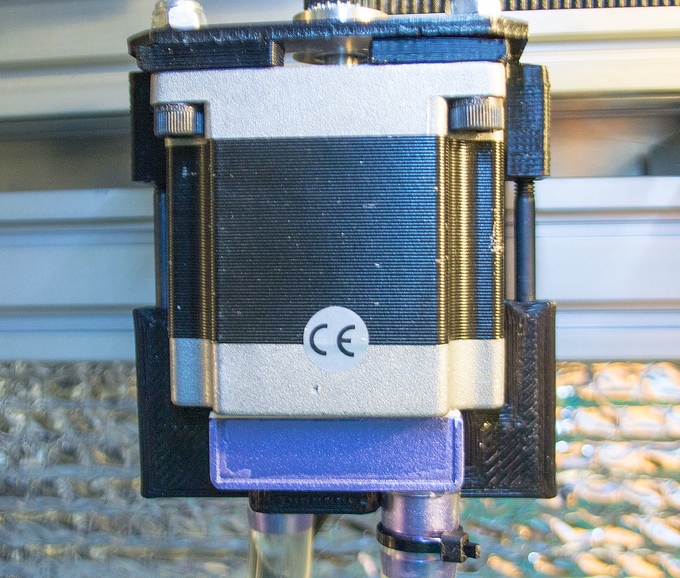

One issue that may occur in a heated chamber is heat creep, where excess heat “creeps” up the extruder to cause plastic to melt in places where it shouldn’t. Normally this is handled by a block of fans towards the top of the hot end, but that is less effective if the ambient air is already quite warm, as would be the case in AON’s heated chamber.

To counteract this, AON has also added an innovative water-cooled extruder! They’ve taken a stock E3D metal extruder and modified it to handle up to 450C, which, as you can imagine, can cause heat creep on its own. The water cooling is also optional, but we suspect it might be a good idea to order both options together.

The AON machine also is built quite robustly:

- They don’t use any 3D printed parts on “any sensitive structural or motion components to ensure long-term, reliable operation even in the heated environment”

- The motion system is built on very high grade components, including precision linear guides, enabling movements up to 500mm/second (but that would be travel speeds, not printing speeds)

All this makes the machine reasonably heavy at 70kg (154 pounds), but if you price this machine by weight, it’s quite a good deal.

For their initial launch, the machine’s price was set at CAD$5,500 (USD$4,000), but those are all gone. The price you’ll see is still quite a good deal at CAD$6,500 (USD$4,800). But remember, this does not include the optional heated chamber and water cooled extruder. Orders today are expected to ship in 5 months, with inevitable price rises after the launch period.

They say it’s for “Real Industrial 3D Printing”, and we don’t doubt it. The AON is a very intriguing machine and at the prices they’ve set for launch it appears to be a very good deal, too. There’s only a few days left in their launch campaign, so be sure to check it out now.

[UPDATE: We’ve been informed that both the heated chamber AND water-cooled extruder are in fact standard items, while you can also order the water-cooled extruder on its own if you wish to upgrade your own E3D setup.]

Via Kickstarter