A new UK-based 3D printer startup has developed an even more flexible dual extrusion approach.

Modix announced the Modix Tango desktop 3D printer with an unusual feature, a completely independent dual extrusion system.

I’ve seen this approach previously, namely in the Kloner3D 240Twin and more recently in the Cosine Additive AM1. However, the Modix folks boast they have the “World’s First Dual 3D Printer”.

I’m not so sure it’s actually the first, as Kloner3D has been doing something like this for about a year. However, when you look deeper, Modix’s approach is a bit different.

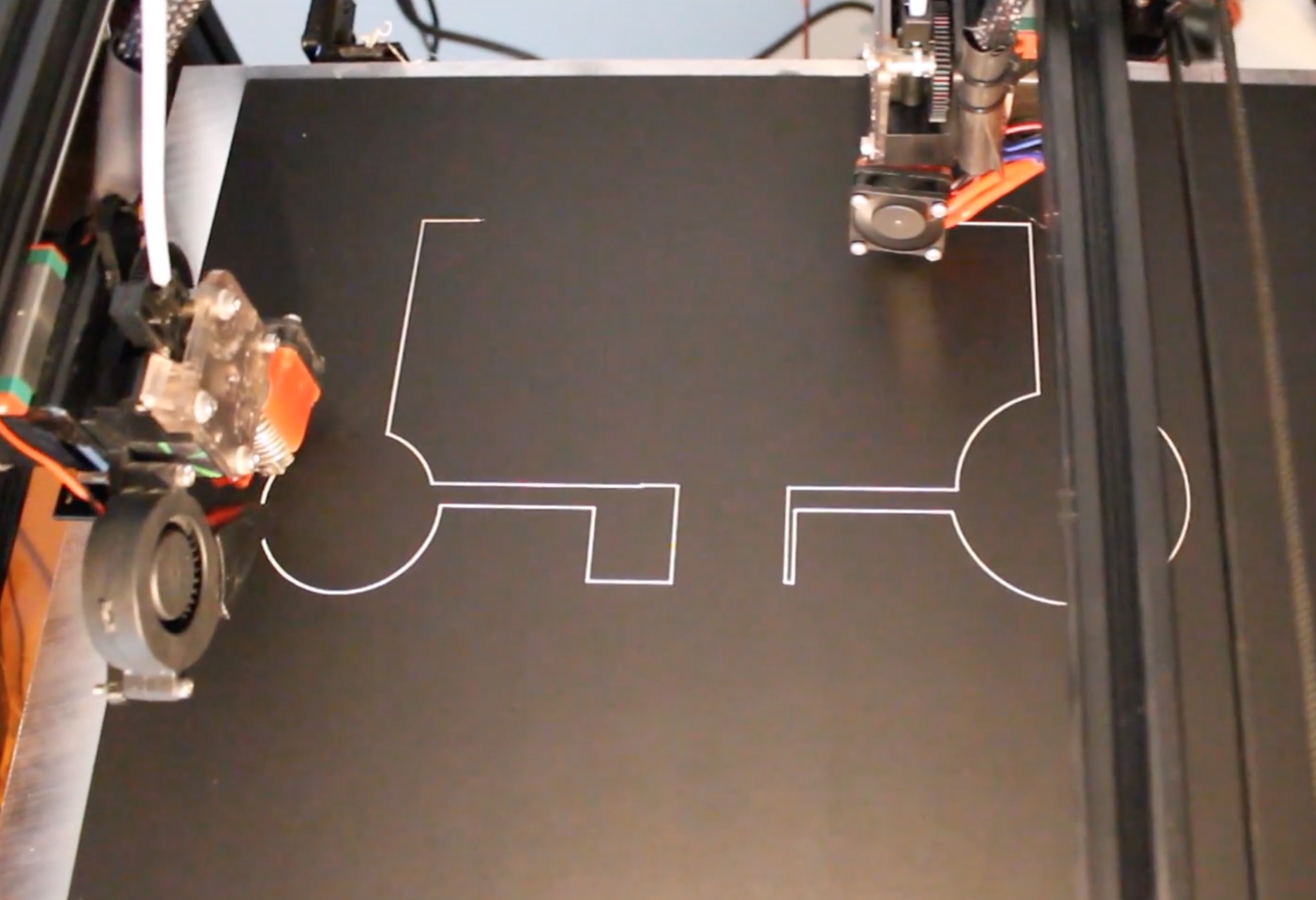

In the Kloner3D approach and others, actually, there is some shared hardware between the dual extruders. For example, they might be independent, but move along a common rail. This limits the capability of a dual approach: only one Y-axis position is possible for both extruders at one time.

However, Modix seems to have completely and entirely separate systems for the extruders, making possible some interesting scenarios.

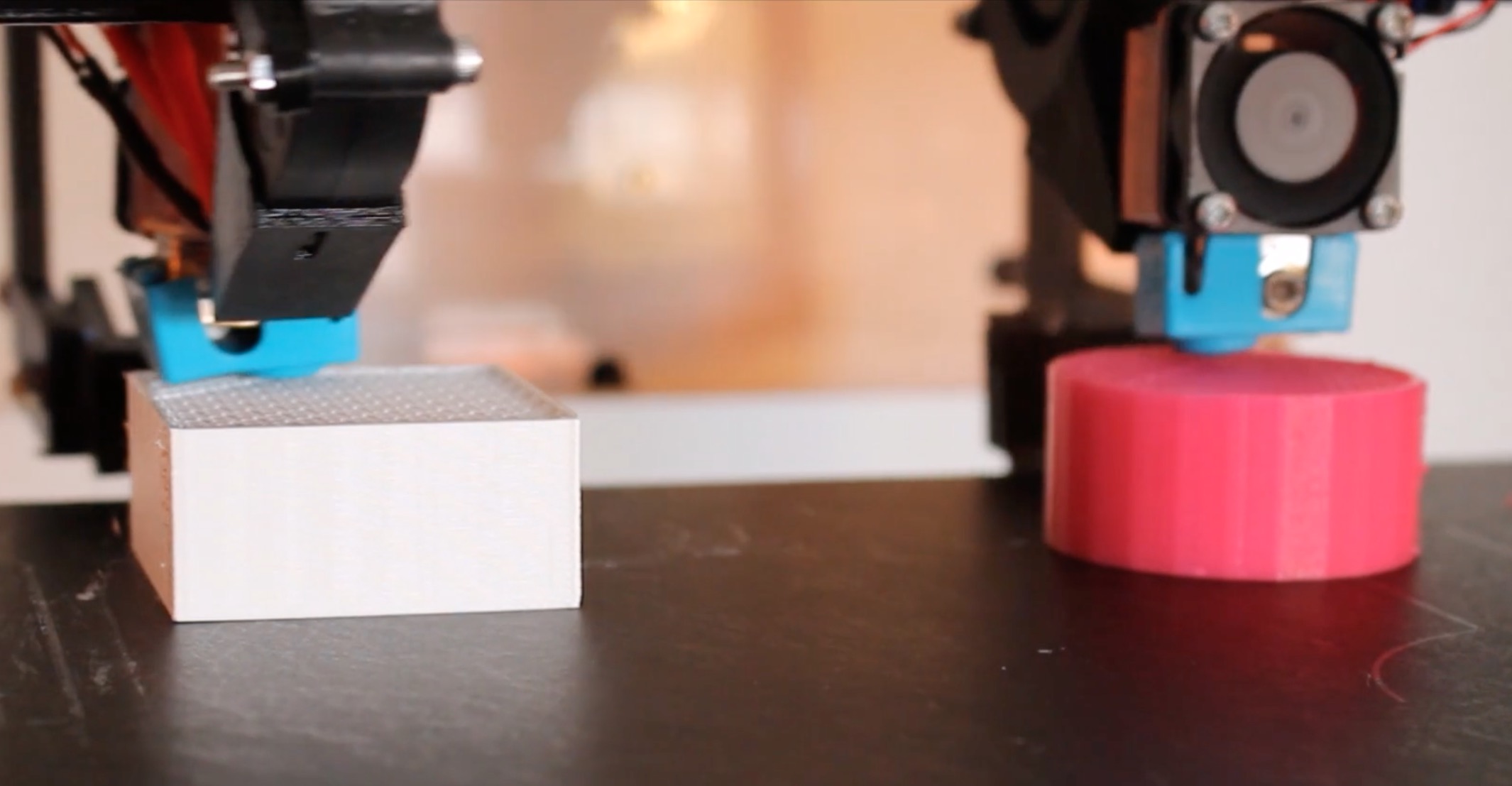

You can print two items at once, each at full speed.

You can print in two different colors at full speed.

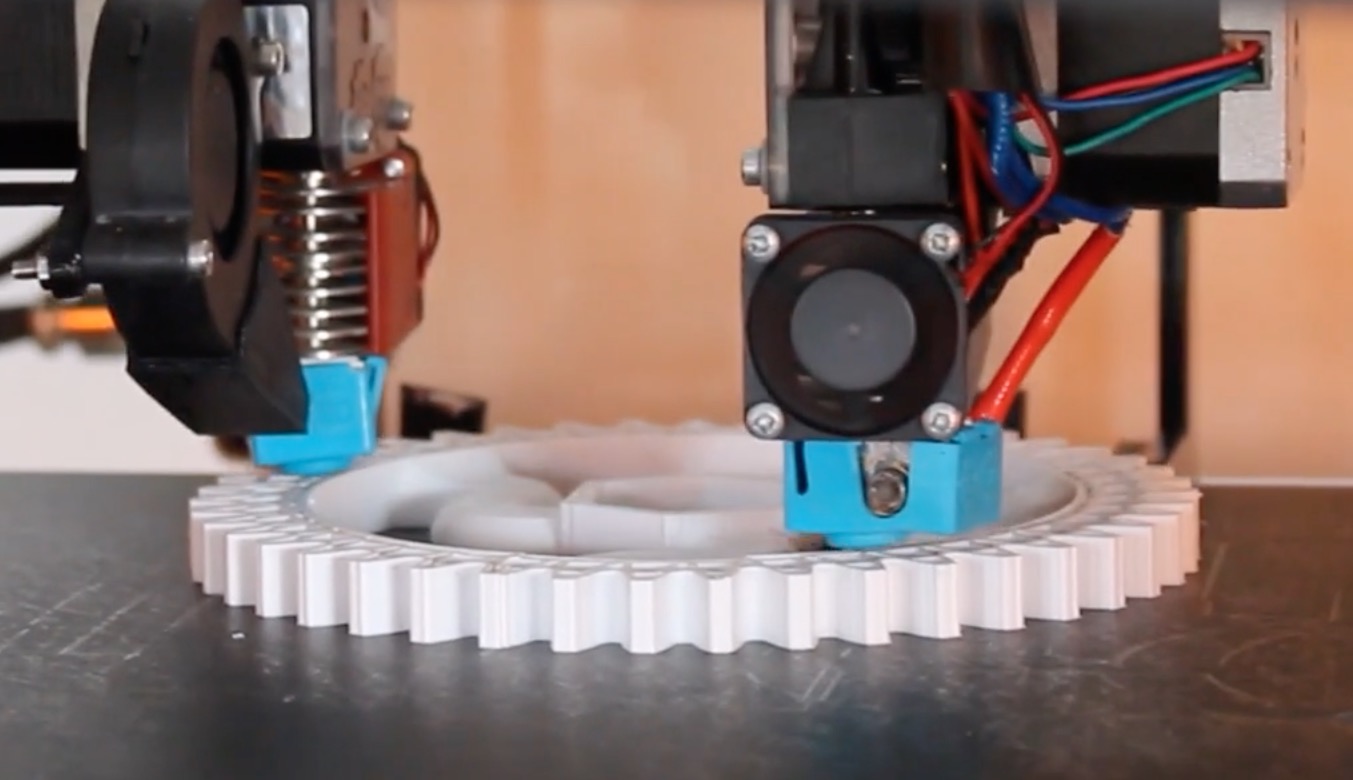

You can print a single object at (almost) twice the speed as both extruders can work on different portions of the object at the same time.

Watch their video to see how it works:

That’s not something I’ve seen previously.

Hold on, I have in a way. There are high-powered industrial metal 3D printers that use multiple lasers to speed printing by using up to four lasers at a time. This is a similar parallel approach, but using extruders instead of lasers. The effect should be the same: more throughput.

The Modix Tango has a build volume of 400 x 400 x 400mm, which is quite generous, although maybe not if two extruders are operating within the same volume. It’s like having two 200 x 200 x 400mm printers in some scenarios, I suppose

There are some other good features, too. The machine includes E3D V6 hot ends and E3D Titan extruders for reliability and performance. The aluminum build plate has a PEI coating for easy adhesion and removal of completed prints.

As of now, this machine is only announced; it’s not yet available and is expected to be released in December along with pricing. I don’t know the price now, but I imagine it might be based on the price of two 3D printers, which is essentially what you’re getting here.

This is an approach to watch.

Via Modix