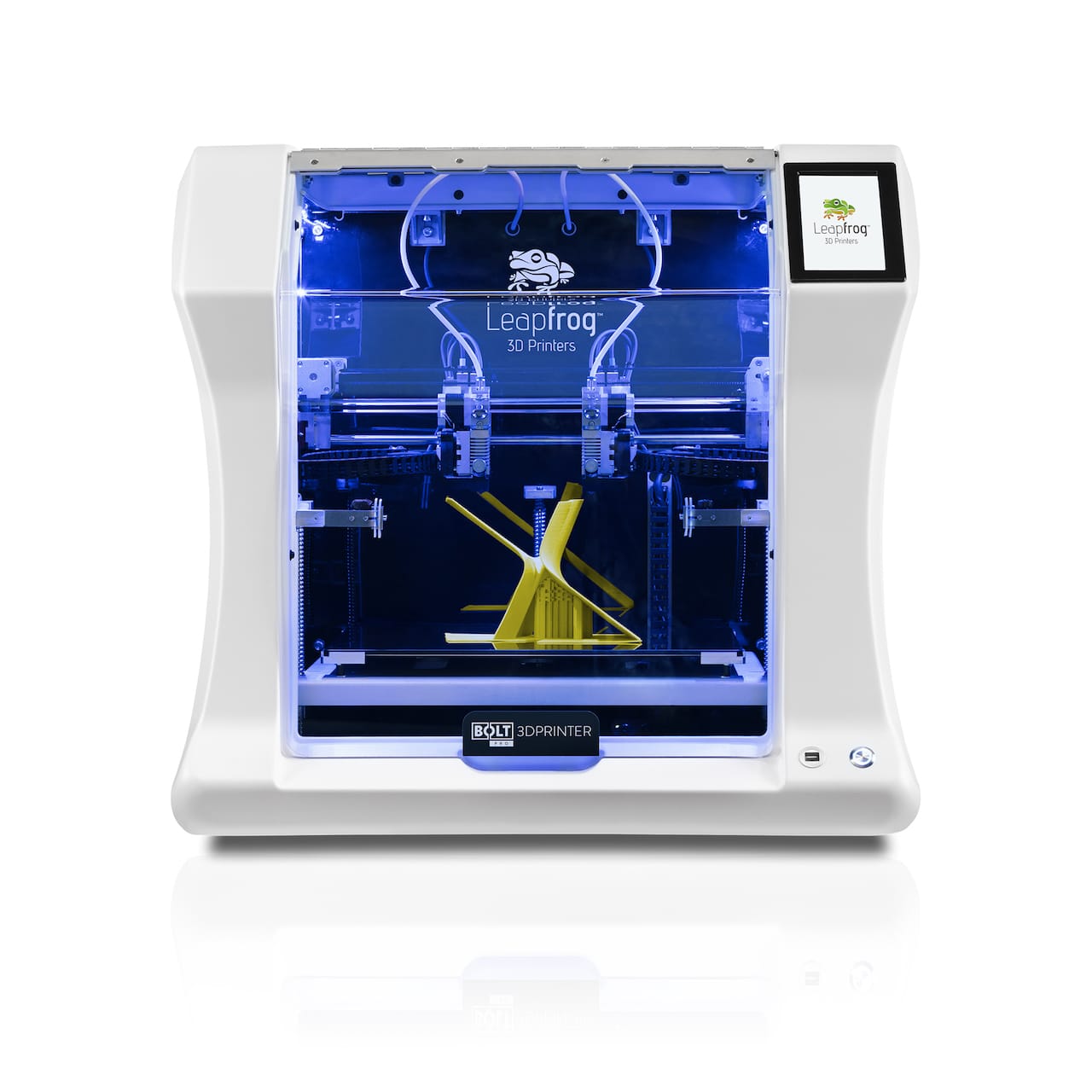

Leapfrog has announced a new flagship 3D printer, the Bolt Pro.

The Netherlands-based company had last year announced the Bolt, a grand departure from their previous models with new features and larger build volumes. The notable feature of the original Bolt was its independent dual extrusion system, which permits printing two different models simultaneously (or two copies, or two materials, etc.)

Now, a year later, they’ve announced the Bolt Pro. What’s different? I looked at the feature changes:

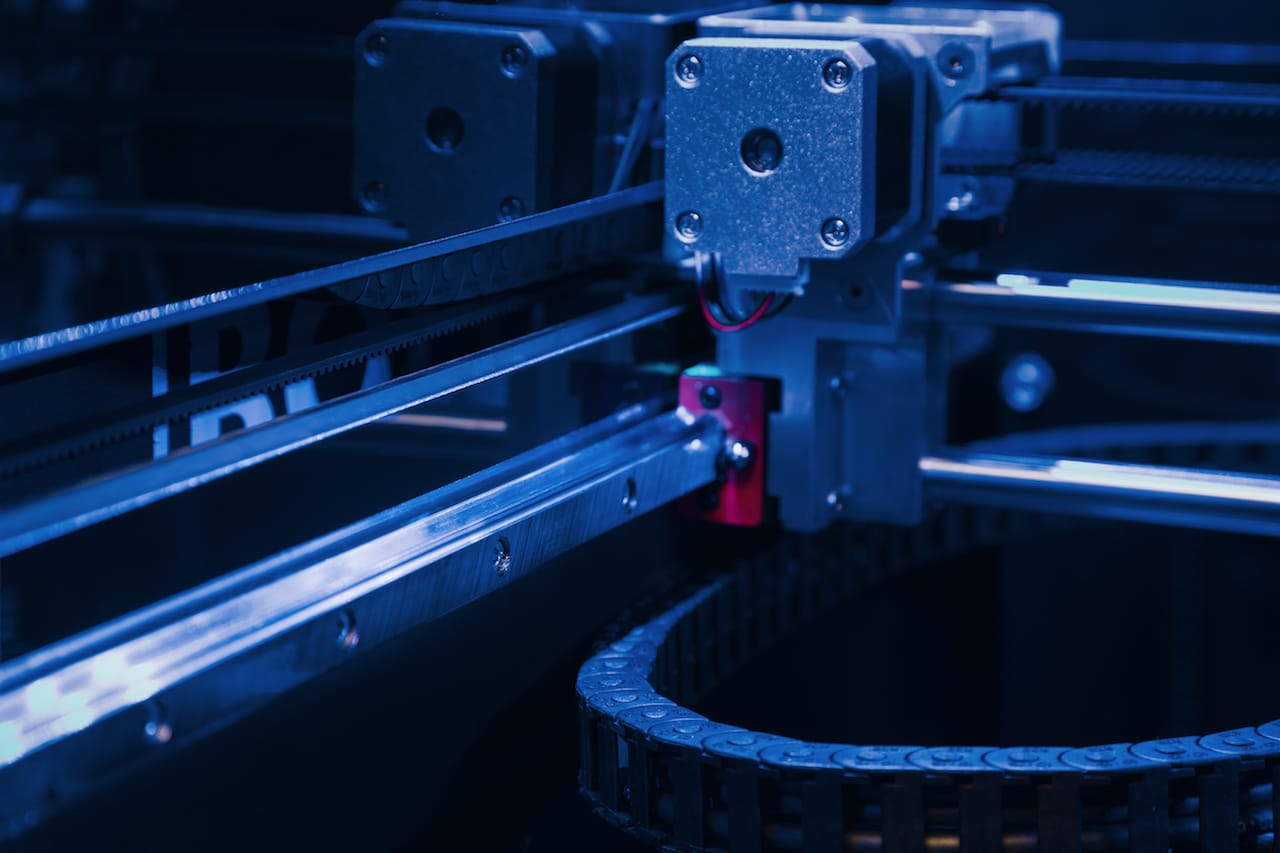

Industrial linear guides in the Y-axis increasing printing precision and reducing noise: This is a good upgrade, as it provides the independent dual extruders with a superior motion system over the previous solid rod system. While the dual extruder system may suggest a requirement for an improvement to the Y-axis, I am wondering why there isn’t a linear guide on the X-axis. However, their detail page says the Bolt Pro “has linear guides“.

Interactive user interface start-up guide: This type of feature is always helpful, but usually only for new installations or operators.

Ability to swap filaments mid-print: I’m not sure why this is a feature, as almost all 3D printers can do this by simply pausing the machine and changing the filament. However, it is very important if your spool is nearing completion. There may be an advantage to being able to do so on a single extruder during a dual print, particularly if you are 3D printing objects serially (whole objects at a time), as you could end up with a print plate containing objects with different materials.

Improved cooling and fan-duct: This, I believe, could be very important for print quality. Cooling is vitally important as the soft extruded plastic should be frozen into shape as soon as possible. It appears Leapfrog is focusing on this, so expect higher quality prints on the Bolt Pro.

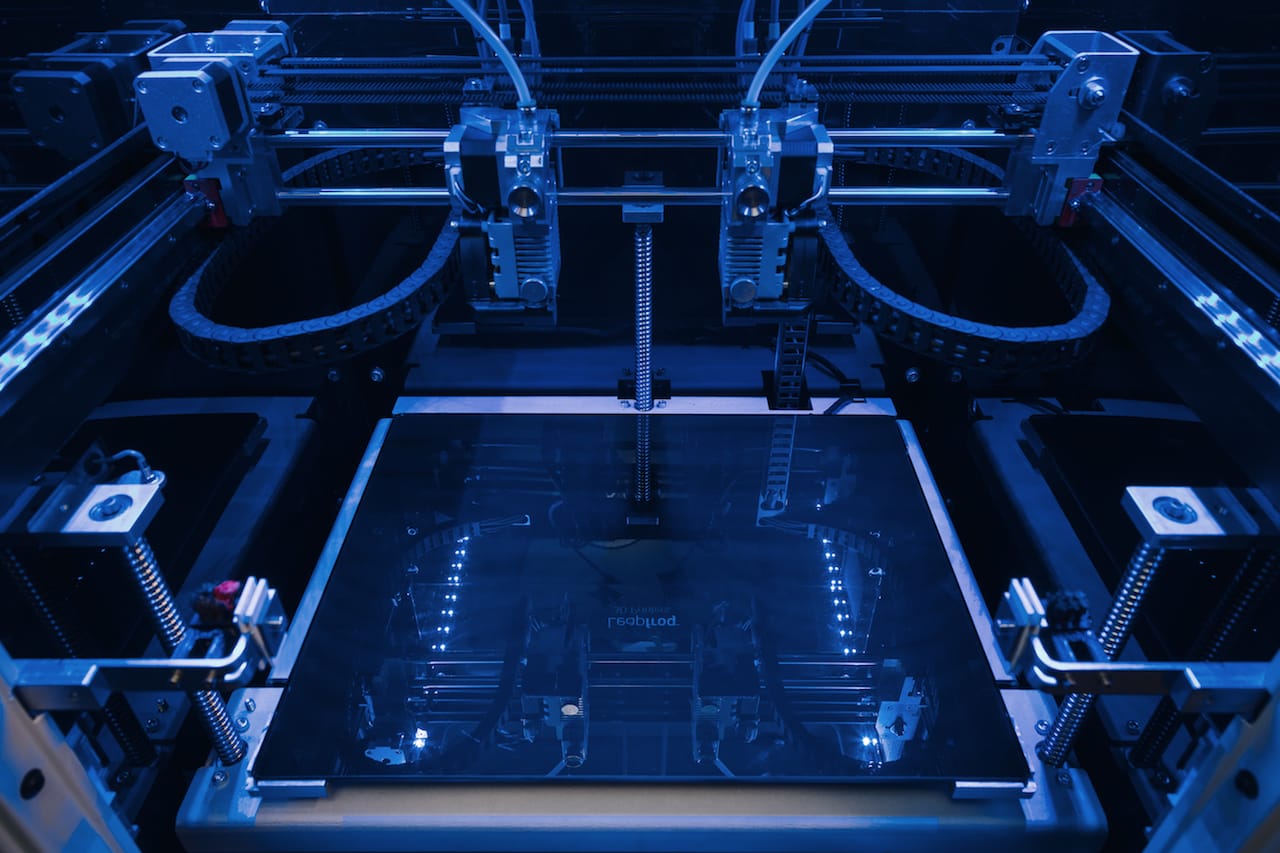

Instantly swappable print beds: with a standard Borosilicate bed and option for granite: Swappable print beds is always important if you are printing continuously, as you can pull out a completed print bed and immediately pop in the next for instant printing. But what I find quite interesting here is the granite option, which would provide the most rigid and flat print surface possible. I’ve seen granite beds in only one other 3D printer, and it was substantially more expensive.

Magnetic closing of doors and filament compartment: A nice feature, but I can’t imagine this will assist much in either usability or print quality.

Improved cabling based on IGUS industrial grade components: This is another key upgrade. Machines that run for long periods do eventually fail, and often its a failure of the cabling system. Older MakerBots, for example, were frequently victim to broken cables due to repeated flexing. Improved cabling in the Bolt Pro should alleviate similar concerns.

RGB LED status indication: Another minor usability feature.

Reading between the lines here, it appears that Leapfrog is tuning their machine for continuous 3D printing. The swappable beds, swappable filament, improved cabling and magnetic doors all should assist an operator that intends on running the machine 24 x 7.

The linear guide feature and fan ducting change should improve print quality as well.

Remember, these are the changes to the Bolt Pro, as the machine inherits all the other characteristics of its predecessor, the Bolt, including the 330 x 320 x 205 large build volume. The machine was already capable of 3D printing exotic materials with its optional 360C hot end and higher quality 3D prints from its all-metal construction and enclosed build chamber.

The Bolt Pro should make this a better option for professional 3D printer operators hoping to run long prints frequently.

The pricing of the system is set at €6,500 (USD$7,260). This is slightly more than the price of the original Bolt at USD$5,500.

Via Leapfrog