Japan-based Mimaki formally announced a new and rather interesting full color industrial 3D printer.

The new machine, the 3DUJ-553 UV LED, is the first 3D printer for the organization, which to this point has produced only 2D color equipment.

But they are a large corporation with decades of experience developing very high quality printing solutions, today making most of their revenue from equipment that can produce large format signage and customized clothing & product prints. They have very significant experience in the color market, unlike most 3D printer companies.

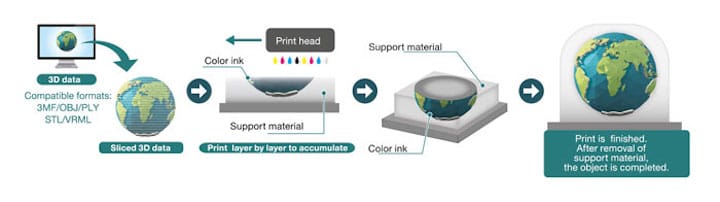

The 3DUJ-553 UV LED uses a somewhat familiar process for 3D printing: they have leveraged their ultra-high resolution liquid inkjet system to selectively deposit “ink” (as they call it) on a surface in layers. An ultraviolet LED subsystem then illuminates the layer and causes solidification.

The 3DUJ-553 UV LED’s inks are really “inks”, as they contain precision pigments, which are deposited pixel by pixel, or I should say, voxel by voxel.

You might wonder how a system depositing liquid can work: overhangs could be challenging. They’ve solved this problem by including a secondary liquid photopolymer that is used to generate support structures. Even better, this material is water soluble, so you simply dunk your full color print in a tub after printing to completely remove all the support material, even on delicate objects.

The results are spectacular, as seen in this example.

Materials required are 1L bottles of CMYK ink, as well as 4.8L bottles of White, Clear and Support materials, purchasable from Mimaki.

The 3DUJ-553 UV LED has an enormous build volume, of 508 x 508 x 305mm, far larger than most 3D printers. However, it’s print speed is quite slow, with the company benchmark for a 100 x 100 x 100mm object at 14.4, 17.0 and 25.7 hours for draft, standard and HD modes respectively.

Combined with the enormoussize, this means that a print occupying the entire build volume would take almost 56 days of continuous operation. However, there is a reason for this: precision.

This machine is perhaps the only full color 3D printer that actually uses true color specifications, as they use the FOGRA39-L specification. All other full color 3D printers seem to ignore the need to precisely match the color of the original design to the print. I believe this is a philosophy the Mimaki machine inherits from the company’s long history in dealing with color challenges in 2D printing. They have that experience, while other 3D printer manufacturers do not.

Otherwise their process seems quite similar to the Stratasys’ PolyJet process, which by no coincidence can also produce full color 3D prints. However, it appears that Mimaki’s can produce more accurate colors: 10M, in fact.

One question I do have is pricing, which could determine the success of this machine in the somewhat limited full color 3D printing market. If their machine is substantially more expensive than Stratasys’ options, they may not make much headway. They are certainly priced at higher levels than less expensive color options, such as MCOR Technologies’, so it remains to be seen where they land.

But definitely a great development for those interested in full color 3D printing.

Via Mimaki