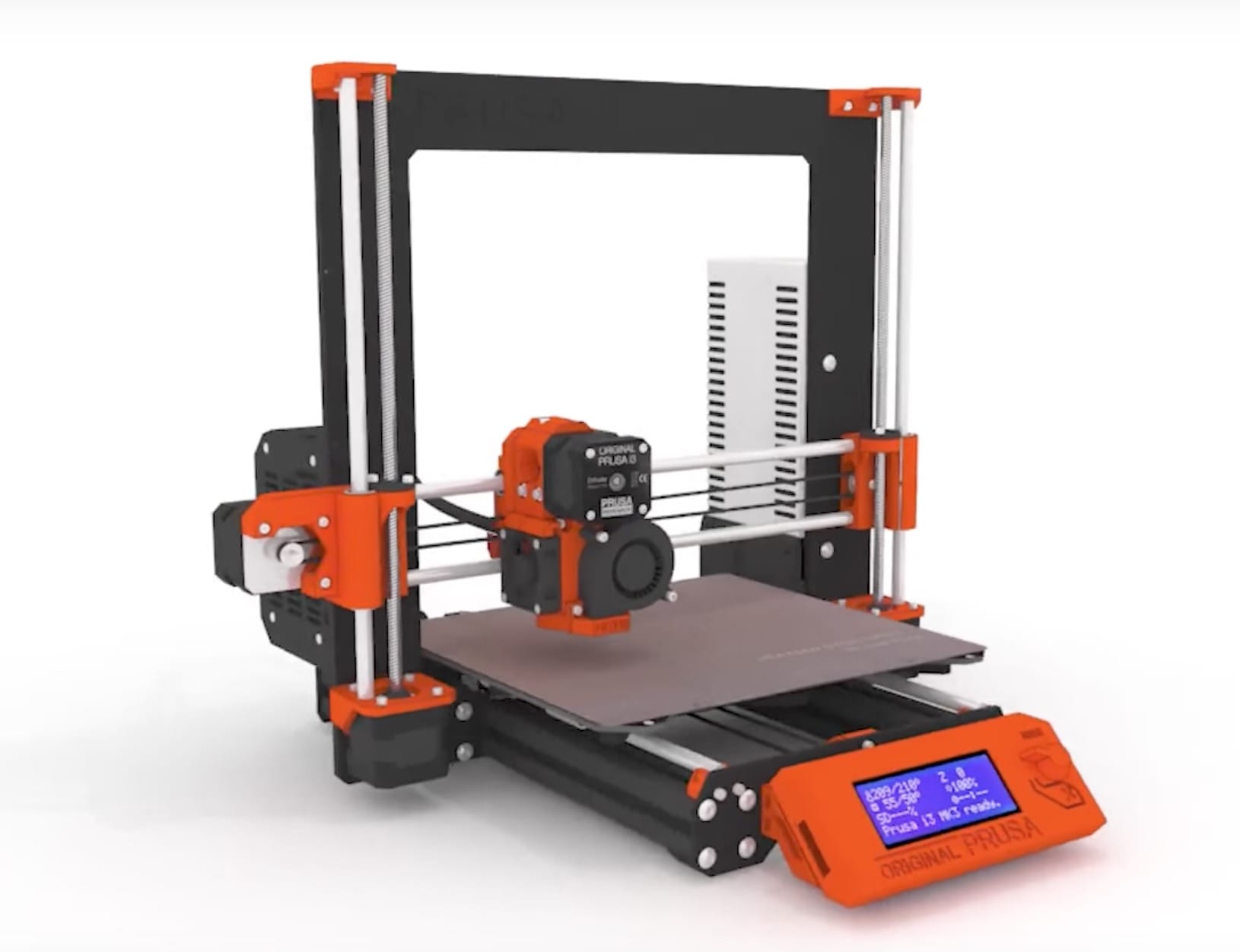

Unexpectedly, Prusa announced a significantly improved desktop 3D printer, the MK3.

Yes, we all expected Prusa to develop and announce a new machine, but what we didn’t know was when. And “when” turned out to be 23 September.

As you might imagine, the MK3’s technology is based on, and is an extension of, their previous MK2. They say it’s “silent, reliable, faster, convenient and smarter”, and all these are entirely true.

Let’s go through the key improvements on the MK3:

Filament sensor: Prusa now includes a laser-based filament sensor that not only detects the presence of filament, but also whether it’s moving appropriately during 3D printing operations. If not, the MK3 declares a “jam” situation, pauses the print and sets up to reload the filament. That’s a lot of manual work during a fault situation that is now done automatically.

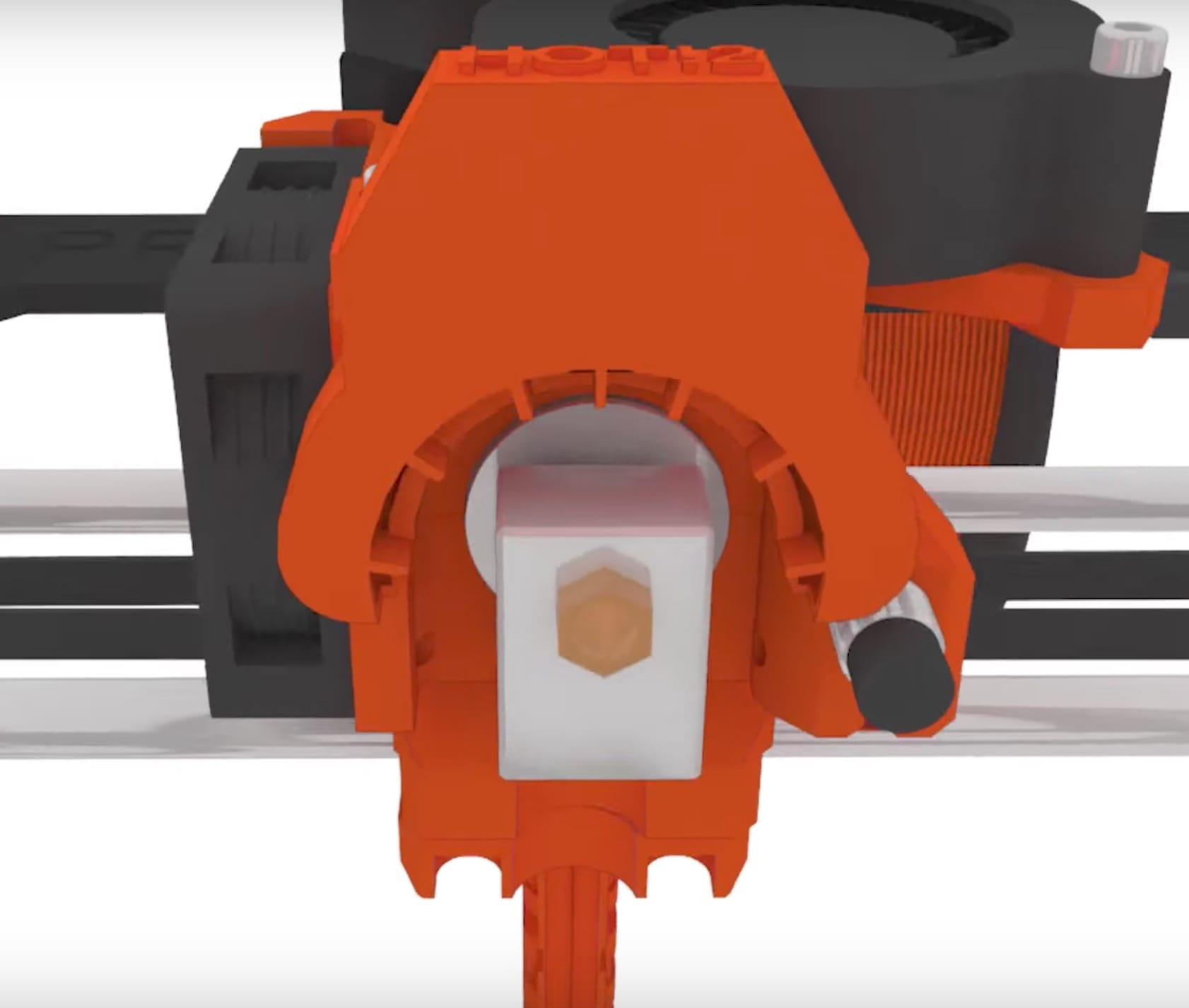

Power Panic: I’ve seen something like this feature on a couple of other machines, but none exactly like this. The MK3 includes a set of capacitors that, when a power outage is detected, pause the print and move the toolhead to parking position. This is important as residual heat from the nozzle might distort the point of contact on the current print. No batteries are used.

RPM sensing fans and Noctua and Ambient thermistor and P.I.N.D.A 2 with thermistor: The MK3 includes several new sensors that provide a variety of reliability features, including these.

EINSY RAMBo motherboard: A new motherboard is the key to many of the new features. The custom developed board includes the ability to detect power loss, enabling not only the power panic mode, but also the ability to detect blown fuses.

Trinamic2130 drivers with layer shift detection, faster and silent printing: Enabled by the new motherboard, the new drivers should make 3D printing operations far smoother and more reliable. According to Trinamic: “Trinamic develops the world’s most sophisticated technology for motion and motor control applications”, and that’s exactly what you’re now getting in the MK3. Note that Prusa now says the maximum print speed on the MK3 is now 200mm/s, over the 100mm/s rate of the MK2S. Wow!

New Y axis: The lower Y-axis structure has been replaced with a more robust design. The extruded aluminum design should provide more rigidity during printing, which is especially important if you are running the MK3 at higher speeds, as above.

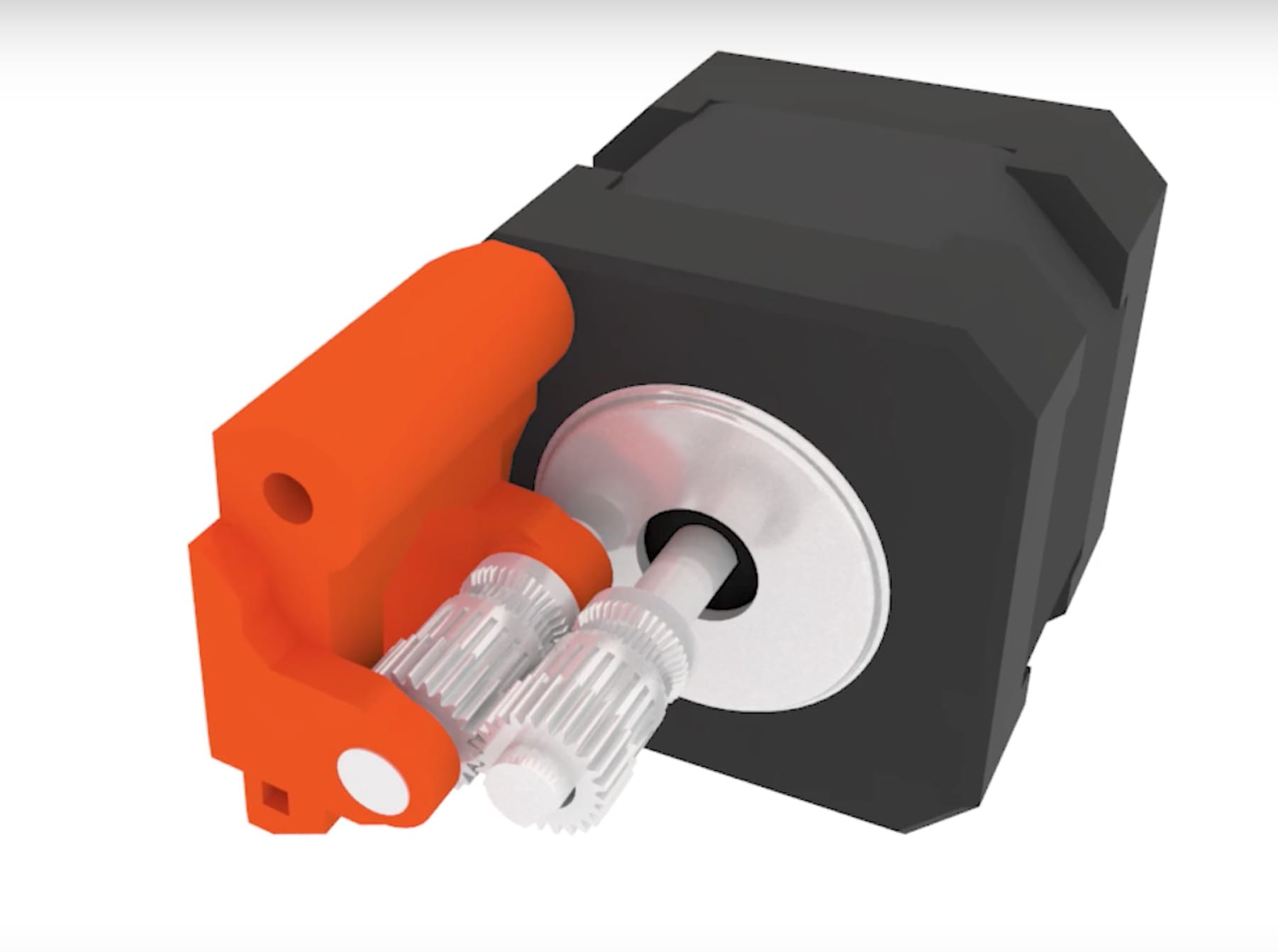

Bondtech extruder: The extruder now includes technology from Sweden-based Bondtech. It’s essentially a dual geared system that grips the filament from both sides. Most filament-based desktop 3D printers have grip from only one side, opposite a friction wheel. The dual Bondtech drive gears should significantly increase reliability and, again, enable higher speed 3D printing.

Magnetic MK52 Heatbed and Powder coated PEI spring steel print sheet: This is perhaps the most visible improved feature. One issue with the previous MK2 is that the print surface is permanently attached to the machine, making it a bit tricky to remove uncooperative overly-adhesive prints. Basically you had to smack the print strongly on the side, but this risks damaging the machine if you’re not careful. Now that problem is entirely gone sa the MK3 includes a removable print surface. And it’s better than that – it is a magnetically attached spring steel plate that, when removed, can be flexed to instantly remove the print.

Ready for OctoPrint: Prusa has smartly decided to install an accessory header on the new motherboard. With this you will be able to quickly install a tiny Raspberry Pie Zero W directly inside the motherboard case on the MK3. Why would you do this? Because you can run wireless set-top box software on it, like OctoPrint. For a mere USD$20 you can install this hardware and software and instantly make your MK3 a “smart” 3D printer with a number of monitoring and control features. Read more about Octoprint here.

All this adds up to a greatly improved desktop 3D printer that, when combined with the low price, should be considered by those seeking a very reliable option.

One thing you may be wondering about is whether you can purchase an upgrade kit to convert your MK2 into a Mk3. Apparently Prusa apparently discussed this extensively, but in the end realized that it is not possible do to so, as there are too many different components; they say “basically, all parts would end up replaced”. So, no MK3 upgrade kit is forthcoming, breaking with their tradition.

However, Prusa realizes MK2 owners would indeed wish for MK3 features, and they’ve arranged what they call a “MK2.5” upgrade, which contains some MK3 features that can actually fit on a MK2 platform. These include: the “magnetic bed with spring steel sheet, whole new extruder head with Bondtech and Noctua fan goodness and also the P.I.N.D.A. 2 bed leveling sensor and filament sensor“. It’s not a MK3, but it’s close. This upgrade kit is priced differently based on your situation. Prusa explains:

The retail MK2 to MK2.5 upgrade price is $199. If MK2S was bought during the last 30 days before this release, it is just $99. If you bought MK2/S before, ever, it will be $149 for you.

But more about the machine pricing. As you might imagine, Prusa has raised the price of the MK3 slightly over the MK2, which itself was reasonably priced. Now the MK3 is available at USD$745 for the kit version, and USD$999 for the assembled version, about USD$100 more than the MK2 pricing.

And about that MK2 pricing, the company has made a reduction. You can today order a MK2S kit for only USD$599, and it’s a very good machine.

These price changes are all good, but the unexpected announcement has caught a number of Prusa customers unaware. I’ve read a number of complaints from those who have recently purchased a MK2 model, only to have the price drop suddenly. Some have not even completed building their MK2 kit when the MK3 appeared.

There’s not much Prusa can do about this, as they have to announce a new machine at some point, and any buyers at the time may encounter this situation. It’s unfortunate, but happens all the time with other products.

Should Prusa have pre-announced the machine well ahead of the release date so folks could make a decision? That’s not really feasible for them either, as such an announcement would have collapsed their current MK2 sales, leaving them with a huge inventory of unsold MK2 machines and parts.

My advice: it’s just bad luck, but even with a MK2, you have an excellent 3D printer.

For those who don’t, check out the new Prusa i3 MK3

Via Prusa Printers