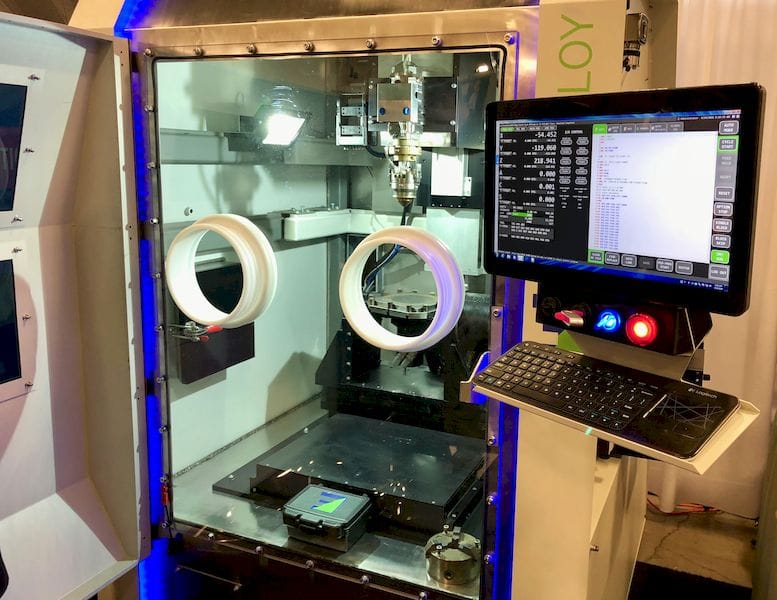

Larger scale 3D metal printing is available with Formalloy’s X-Series.

The San Diego-based company is only two years old, but today they market not one, but two 3D metal printing systems. One, the L-Series targeted at labs, is a small-volume version of their larger machine, the X-Series.

But the X-Series is much larger, and has a build volume that can be “millimeters to meters”, depending on what you want to order.

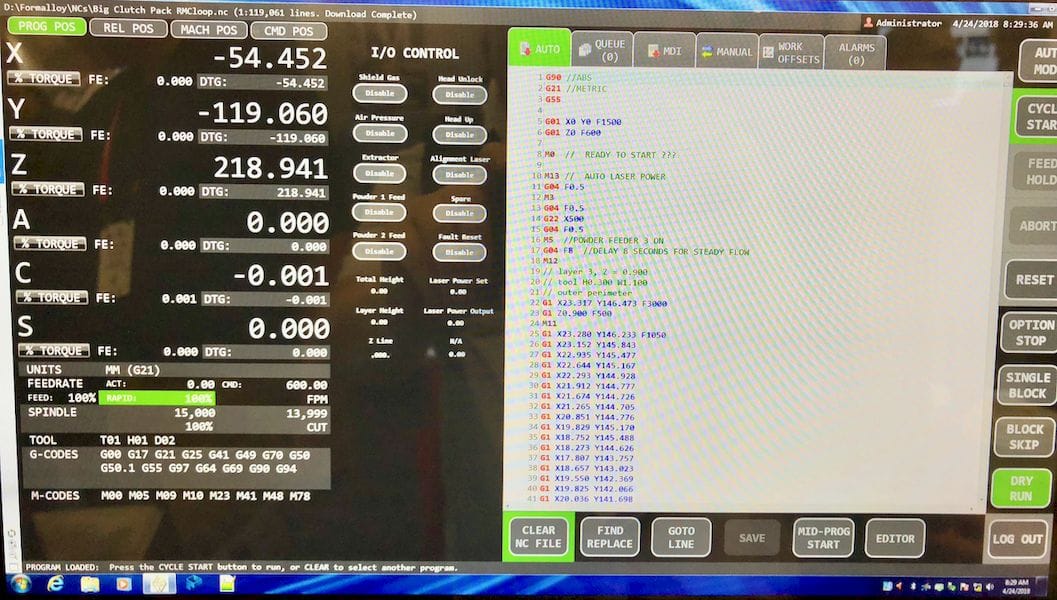

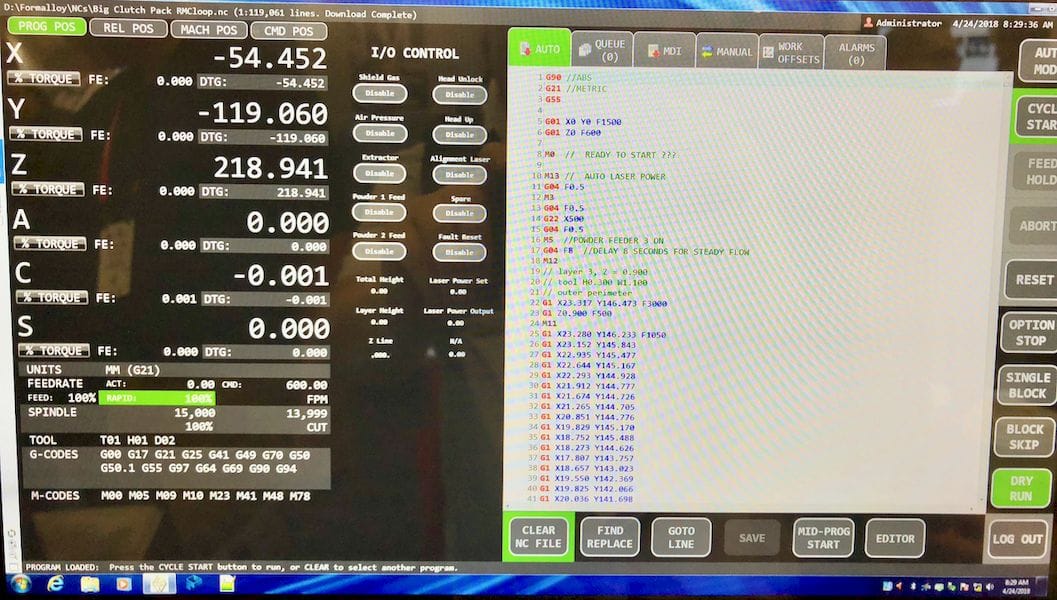

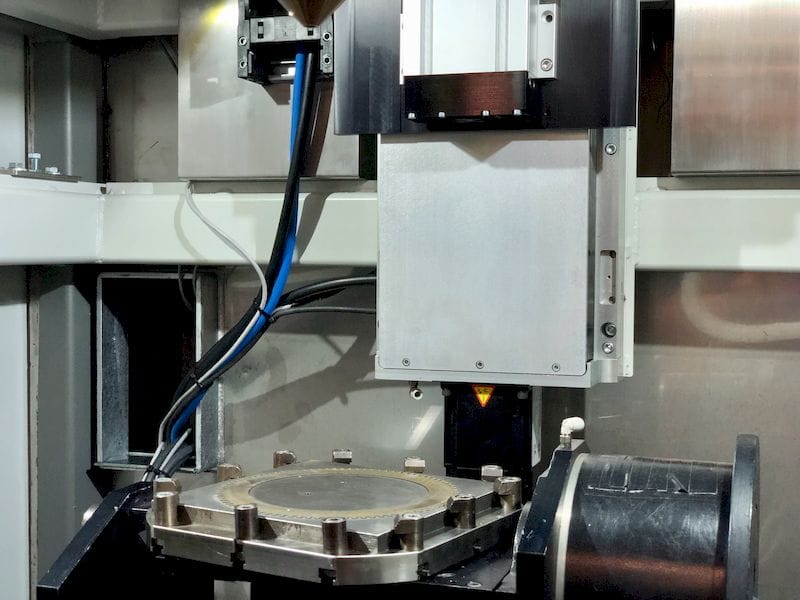

The machine uses a process they call “Laser Metal Deposition”, or LMD. A stream of metal powder is jetted out and a high power laser hits this stream, instantly melting it for deposition.

There are two very interesting aspects to their process.

First, the “Formax” nozzle is of a coaxial design. The laser beam itself is emitted from the center, while the powder stream emerges from all sides in a 360 degree manner. Think of it like a donut, with the beam in the center, and the metal as the donut. I am not certain if any other powder-jet laser approaches do this, but it would likely increase the build quality as the powder deployment would be uniform regardless of the direction of movement.

The second interesting aspect is that the machine’s motion system is optionally a 5-axis design. This means that unlike the very common 3-axis machines one usually encounters, the Formalloy X-Series can rotate the print around during printing. This means they can potentially eliminate the need for support structures: just tip the print over a bit to eliminate the overhang temporarily. By gyrating the print in different directions, you should not require support material at any time.

The system works very rapidly, able to deposit up to an astounding 7kg per hour, far more than typical 3D metal printers.

Even better, the feeder system for the nozzle is built with up to four feeds. This means you can equip this machine with four different powdered metals and mix them on the fly, creating dynamic alloys – hence the company’s name. They say they’ve been able to 3D print in nickel, iron, cobalt and tungsten carbide.

They claim a powder efficiency (which I take to mean the amount of powder attached to the print rather than leftover on the build chamber’s floor) at a very high 95%, meaning you won’t have that much to clean up with this machine.

The prints from this machine won’t be as finely detailed as available in some other processes, but there is plenty of room for this style of equipment in the market.

Pricing is quite reasonable for this equipment, given its print speed: USD$250K for the base model of the X-Series. However, there are a number of options that you likely would consider, including the 5-axis upgrade, laser power level, inert gas build chamber and more, which could raise the price somewhat.

Yet another competitor in the now-fierce 3D metal printing business.

Via Formalloy