![A tiny 3D printed metal object using the screen printing process [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c8cce27.jpg)

We ran across a metal 3D printing process we had not seen previously: screen printing.

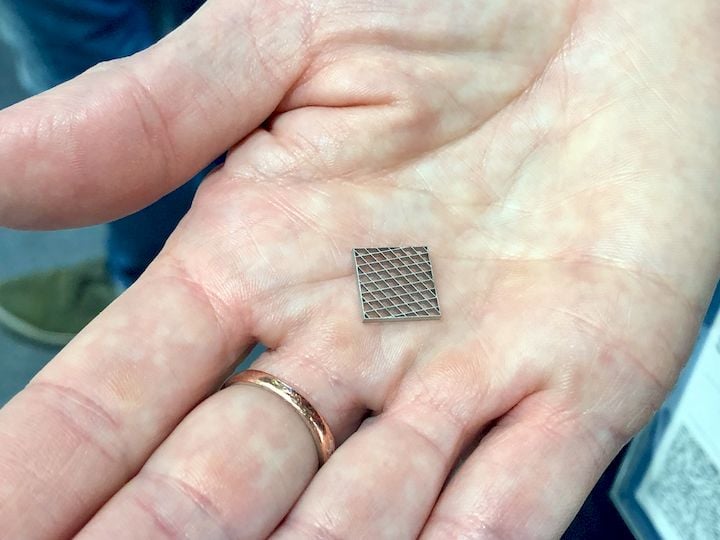

The process, developed by the Fraunhofer Institute, is currently licensed by several commercial firms, including H.C. Starck, who produced this detailed anti-scatter grid collimator for radiation imaging in a tungsten heavy alloy.

![A tungsten anti-scatter grid collimator 3D printed using the screen process [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c9064e1.jpg)

The process doesn’t work for everything, but does very well for certain simple geometries. Thus it is unsuitable for producing lattice-filled aerospace parts, for example. But it is entirely usable for producing small metal parts such as gears, plates and filters.

![Illustrating the size of possible 3D scren prints [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c93ac2f.jpg)

The screen printing process is very much like the 2D screen printing process. Essentially a printing paste made from a mix of material powder and binder is pushed through a fine mesh, but some of the mesh is protected by a layer stencil. The resulting layer is then added on by subsequent layers, eventually producing a complete object.

![The 3D screen printing process overview [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c968235.jpg)

But that’s an object made from binder and material, and thus post-printing steps are required to remove the binder and sinter the material particles together. This means the screen printing process is capable of making objects in both ceramics and metal. And thermoplastics, I suppose, but there are easier and more common 3D printing processes for those.

![The fine screen used in the 3D screen printing process [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c99899c.jpg)

The sintering and binder removal processes result in a reduction in volume of the object by around 20%, and thus printer operators would have to plan ahead by making their print dimensions about 20% larger than desired.

If that 20% shrinkage factor sounds familiar, it should. This is because the screen printing process uses standard metal injection molding powders. Many MIM powders are commonly available in most markets, and number in the thousands. This makes the screen printing process quite suitable if you have an unusual material on your requirements list.

![Tiny 3D printed metal gears made with the screen printing process [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0c9c541f.jpg)

The only requirement is that the metal (or ceramic) particles must be less than 0.03mm in size, otherwise they won’t pass through the fine screen mesh and be successfully deposited.

The layer size of the screen printing process is 0.08mm, which is decently small for fine-resolution objects.

You might be wondering about support structures, and it’s not clear that they can be done using this process. However, we were told that it is possible to print unsupported bridges within the geometry of up to 3mm in distance.

This is an unusual 3D printing process that has some advantages:

-

High-resolution objects possible

-

Metal and ceramic materials

-

Wide selection of materials from MIM catalogs

But there are some disadvantages, too:

-

Small object size

-

Restricted geometries

As always, choose the right tool for the problem. Screen printing is just another tool in the 3D printing toolbox.

Via H.C.Starck

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.